55365

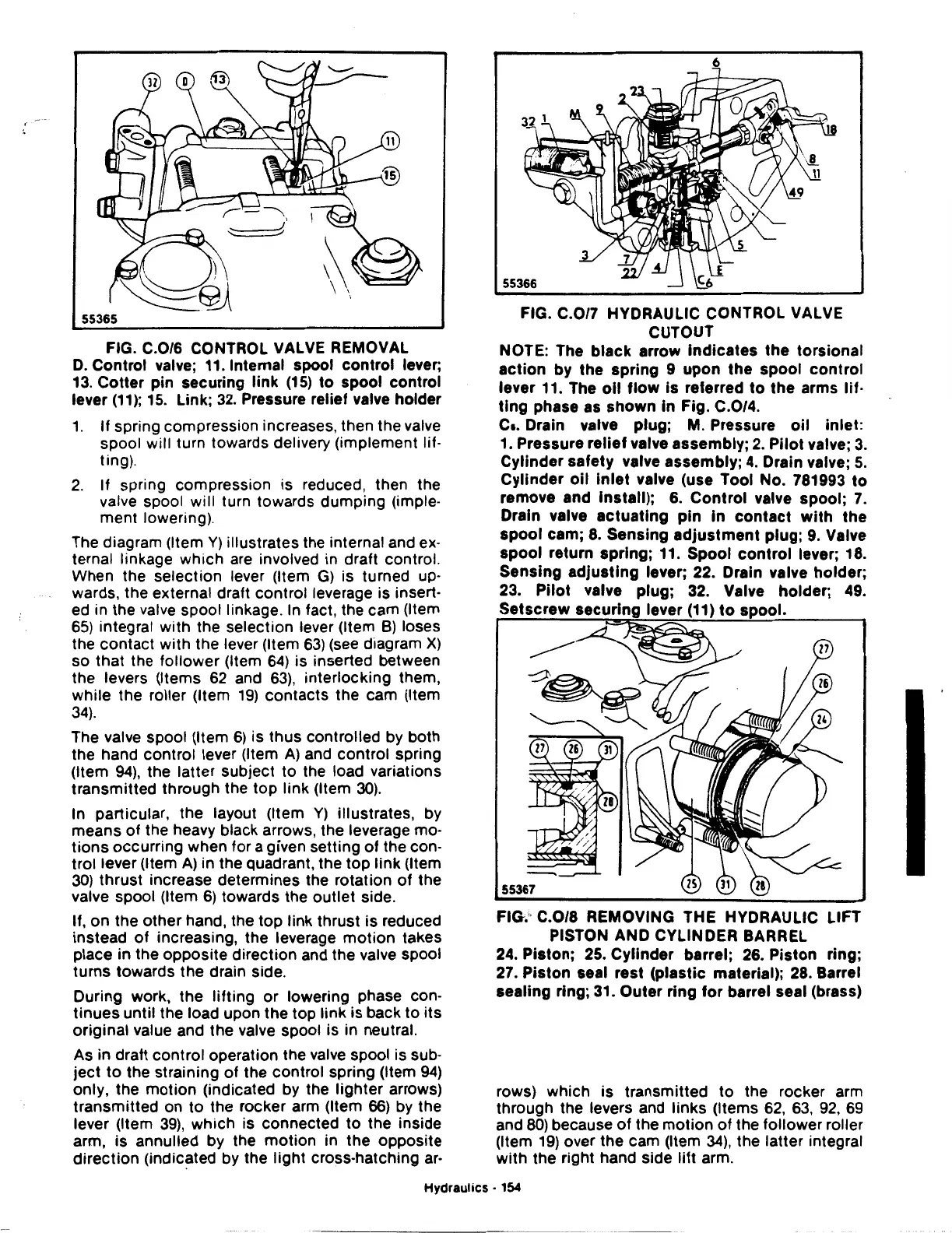

FIG. C.0/6 CONTROL VALVE REMOVAL

D.

Control valve; 11. Internal spool

control

lever;

13.

Cotter

pin securing

link

(15)

to

spool control

lever

(11

);

15.

Link;

32.

Pressure relief valve holder

1.

If

spring compression increases, then the valve

spool will turn towards delivery (implement lif·

ting).

2.

If spring compression is reduced, then the

valve spool will turn towards dumping (imple·

ment

lowering).

The diagram (Item

Y)

illustrates the internal and ex·

ternal linkage

which

are involved in draft control.

When the selection lever (Item

G)

is turned up·

wards, the external draft control leverage is insert·

ed in the valve spool linkage. In fact, the cam (Item

65)

integral

with

the selection lever (Item

B)

loses

the

contact

with

the lever (Item

63)

(see diagram

X)

so that the

follower

(Item

64)

is inserted between

the levers (Items

62

and

63),

interlocking them,

while the roller (Item

19)

contacts the cam (Item

34).

The valve spool (Item

6)

is

thus

controlled by both

the hand control lever (Item

A)

and control spring

(Item

94),

the latter subject

to

the load variations

transmitted through the

top

link (Item

30).

In particular, the layout (Item

Y)

illustrates, by

means

of

the heavy black arrows, the leverage

mo·

tions

occurring when for a given setting

of

the con-

trol lever (Item

A)

in the quadrant, the

top

link

(Item

30) thrust increase determines the rotation

of

the

valve spool (Item

6)

towards the

outlet

side.

If,

on

the

other

hand, the

top

link

thrust is reduced

instead

of

increasing, the leverage

motion

takes

place in the opposite direction and the valve spool

turns

towards the drain side.

During work, the

lifting

or

lowering phase con-

tinues

until the load upon the top link

is

back

to

its

original value and the valve spool is in neutral.

As in draft control operation the valve spool is sub-

ject

to

the straining

of

the control spring (Item

94)

only, the

motion

(indicated by the

lighter

arrows)

transmitted on

to

the rocker arm (Item

66)

by the

lever (Item

39),

which

is connected

to

the inside

arm, is annulled by the

motion

in the opposite

direction

(indicated by the

light

cross-hatching

ar-

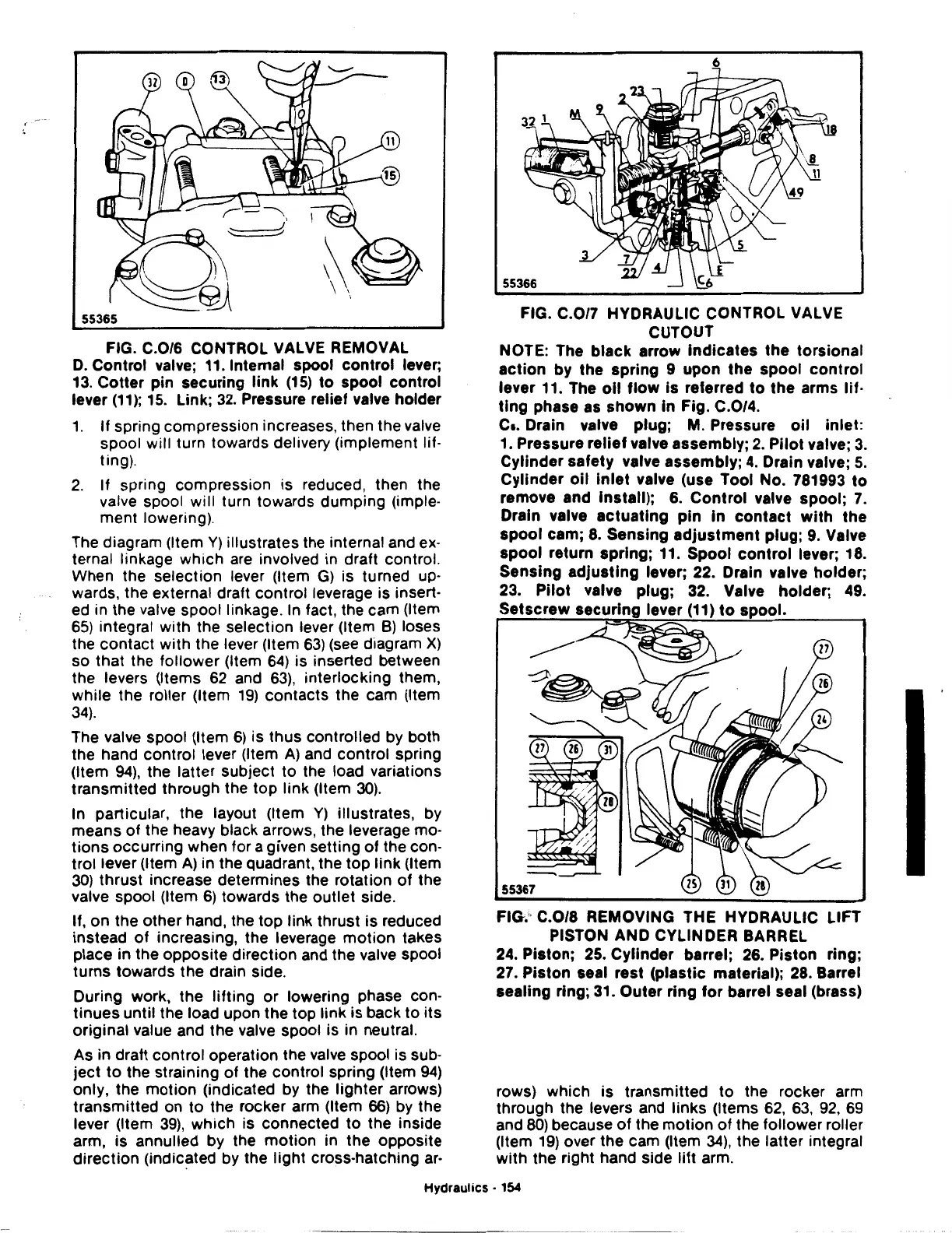

FIG.

C.0/7

HYDRAULIC CONTROL VALVE

CUTOUT

NOTE: The

black

arrow

Indicates

the

torsional

action

by

the

spring

9

upon

the

spool

control

lever 11. The

oil

flow

is

referred

to

the

arms

lif·

tlng

phase as

shown

In Fig. C.0/4.

c

•.

Drain valve

plug;

M. Pressure

oil

inlet:

1. Pressure

relief

valve

assembly;

2.

Pilot

valve;

3.

Cylinder

safety

valve

assembly;

4.

Drain valve;

5.

Cylinder

oil

Inlet

valve (use Tool No. 781993

to

remove and Install); 6.

Control

valve

spool;

7.

Drain valve

actuating

pin

In

contact

with

the

spool

cam;

8.

Sensing

adjustment

plug;

9.

Valve

spool

return

spring;

11.

Spool

control

lever; 18.

Sensing

adjusting

lever; 22. Drain valve

holder;

23.

Pilot

valve

plug;

32. Valve

holder;

49.

lever 1)

to

s

55367

FIG.'·

C.0/8

REMOVING THE HYDRAULIC LIFT

PISTON AND CYLINDER BARREL

24.

Piston;

25.

Cylinder

barrel;

26.

Piston

ring;

27.

Piston

seal

rest

(plastic

material); 28. Barrel

sealing

ring; 31.

Outer

ring

for

barrel seal (brass)

rows) which is transmitted

to

the rocker arm

through the levers and links (Items

62, 63,

92,

69

and

80)

because

of

the

motion

of

the follower roller

(Item

19)

over the cam (Item

34),

the latter integral

with

the right hand side

lift

arm.

Hydraulics

· 154

Loading...

Loading...