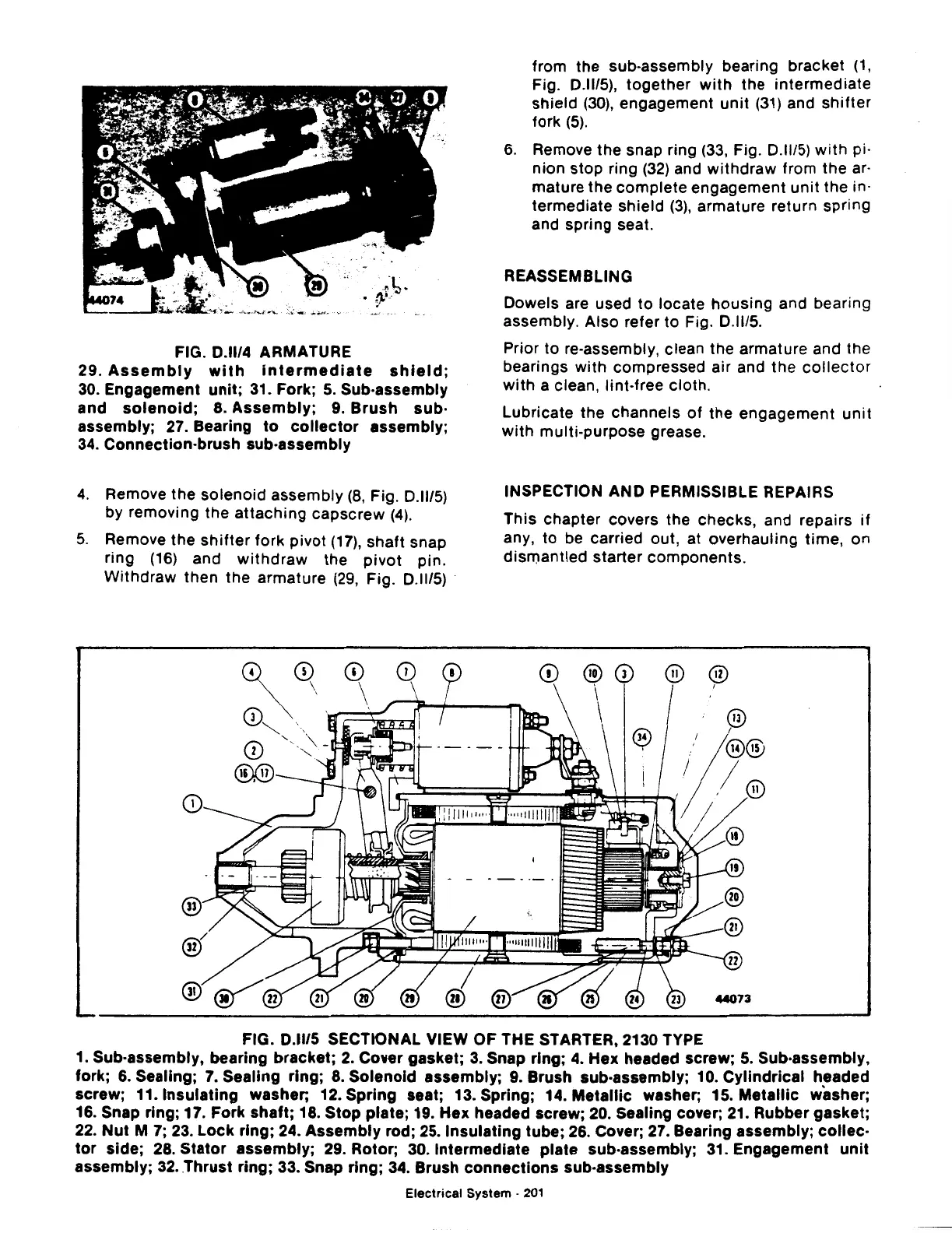

FIG.

0.11/4

ARMATURE

29.

Assembly

with

intermediate

shield;

30.

Engagement

unit;

31. Fork;

5.

Sub-assembly

and

solenoid;

8.

Assembly;

9.

Brush

sub·

assembly; 27. Bearing

to

collector

assembly;

34.

Connection-brush sub-assembly

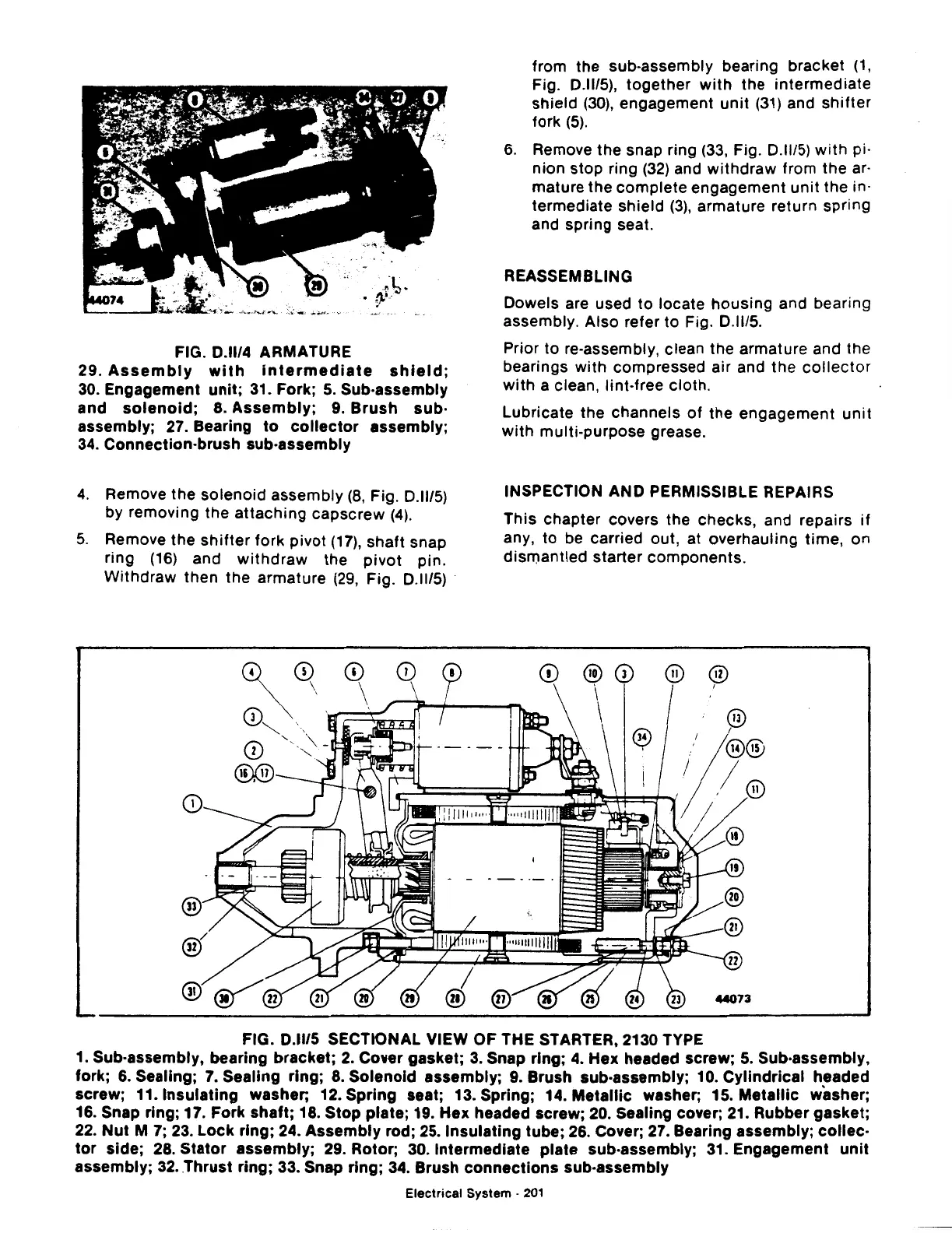

4.

Remove the

solenoid

assembly

(8,

Fig.

0.11/5)

by removing the

attaching

capscrew

(4).

5.

Remove the

shifter

fork

pivot

(17),

shaft

snap

ring

(16)

and

withdraw

the

pivot

pin.

Withdraw

then the armature

(29,

Fig.

0.1115)

·

from the sub-assembly bearing bracket

(1,

Fig.

0.1115),

together

with

the

intermediate

shield

(30),

engagement

unit

(31)

and

shifter

fork

(5).

6.

Remove the snap ring

(33,

Fig.

0.1115)

with

pi·

nion

stop

ring

(32)

and

withdraw

from the ar·

mature the

complete

engagement

unit

the in·

termediate shield

(3),

armature return spring

and spring seat.

REASSEMBLING

Dowels are used

to

locate

housing

and bearing

assembly. Also refer

to

Fig.

0.1115.

Prior

to

re-assembly, clean the armature and the

bearings with compressed

air

and the

collector

with

a clean, lint-free cloth.

Lubricate the channels

of

the

engagement

unit

with

multi-purpose grease.

INSPECTION AND PERMISSIBLE REPAIRS

This chapter covers the checks, and repairs

if

any,

to

be carried out, at overhauling

time,

on

dismantled

starter components.

FIG.

0.1115

SECTIONAL VIEW OF THE STARTER, 2130 TYPE

1. Sub-assembly, bearing bracket;

2.

Cover gasket;

3.

Snap ring;

4.

Hex

headed screw;

5.

Sub-assembly,

fork; 6. Sealing;

7.

Sealing ring;

8.

Solenoid

assembly; 9. Brush sub-assembly; 10.

Cylindrical

headed

screw; 11.1nsulating washer; 12.

Spring

seat; 13. Spring; 14.

Metallic

washer; 15.

Metallic

washer;

16. Snap ring; 17. Fork

shaft;

18.

Stop

plate; 19.

Hex

headed screw; 20. Sealing cover; 21. Rubber gasket;

22.

Nut

M 7; 23.

Lock

ring; 24.

Assembly

rod; 25.1nsulating tube; 26. Cover; 27. Bearing assembly;

collec-

tor

side; 28.

Stator

assembly; 29. Rotor; 30. Intermediate plate sub-assembly; 31. Engagement

unit

assembly; 32 ..

Thrust

ring; 33. Snap ring; 34. Brush

connections

sub-assembly

Electrical System ·

201

Loading...

Loading...