Starting up

- 38 - 01.21909.2669.9-02

14 Starting up

14.1 Electrode welding process

Select the electrode welding process with button 30 (LED

electrode- DC 33 or LED electrode- AC 34 lights up).

9 You are in the parameter main current I1 (LED Main current

I1 37 lights up).

Use the rotary knob 41 to set the desired current intensity.

9 Your welding machine is now ready for use.

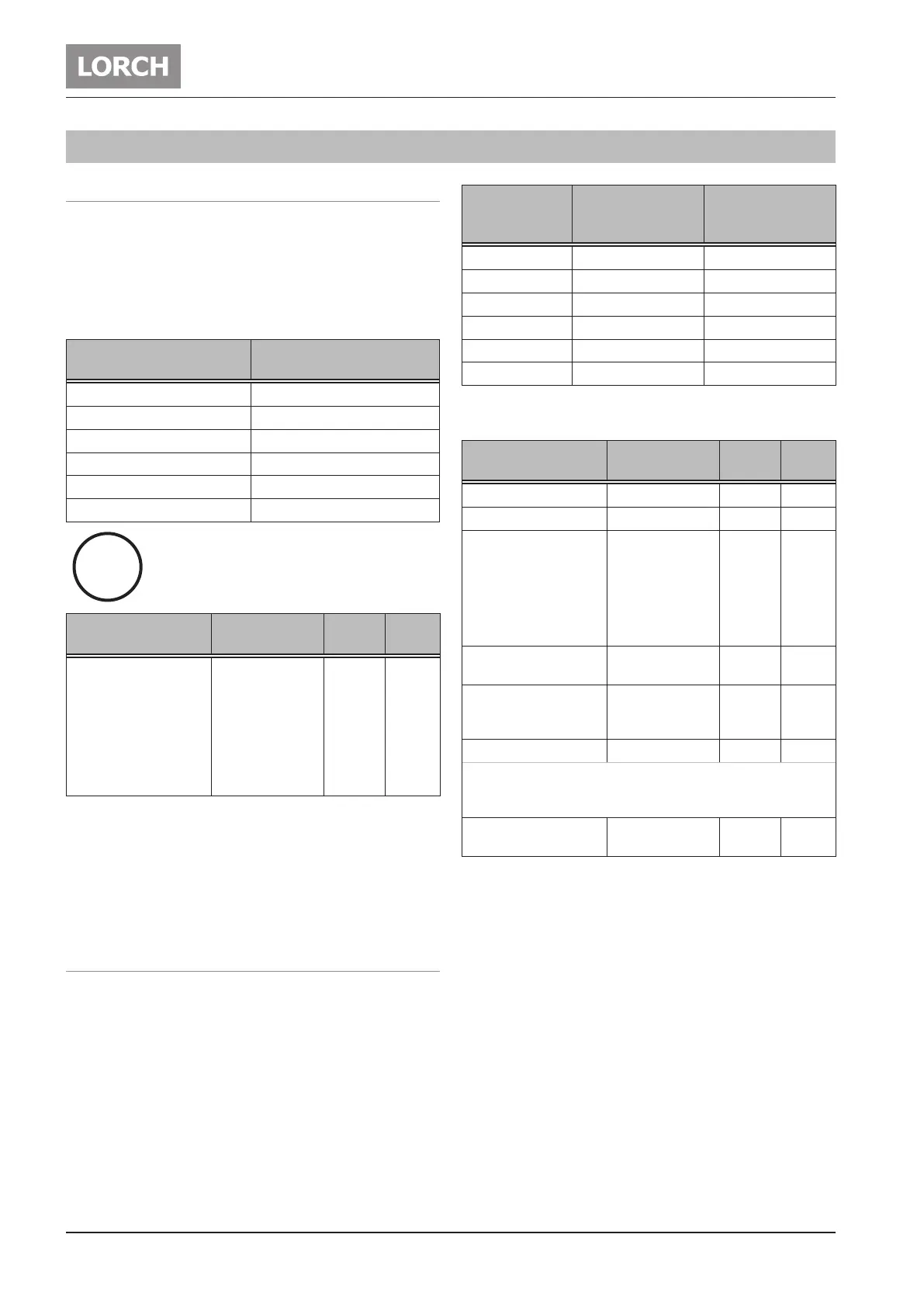

Electrode diameter [mm]

Recommended current

intensity [A]

1,5 20 - 40

2,0 35 - 60

2,5 45 - 100

3,2 75 - 140

4,0 130 - 190

5,0 180 - 260

Heed the electrode manufacturer’s instruc-

tions.

Parameter Range

Factory

setting

LED

Main current I1

100 37

T 180 10 - 150 A

T 220 AC/DC 10 - 170 A

T 220 DC 10 - 180 A

T 250 10 - 200 A

T 300 10 - 200 A

Tab. 1: Main parameters

The factory setting values are optimised thanks to automatic

parameters.

You can use these factory settings unchanged for most weld-

ing jobs.

Further ne adjustment facilities can be found in Chapter „14.3

Secondary parameters“ on page 39.

14.2 TIG welding process

Select the TIG welding process with button 30 (LED TIG-

DC 31 or LED TIG- AC 32 lights up).

Select the desired mode with button 47 (LED 2-stroke 44,

LED 4-stroke 45 or LED Pulse 46 lights up).

48 Press the main parameter button on the bottom right

until the desired parameter appears (the corresponding

LED 35 - 43 lights up).

Use knob 41 to set the desired value.

9 Your welding machine is now ready for use.

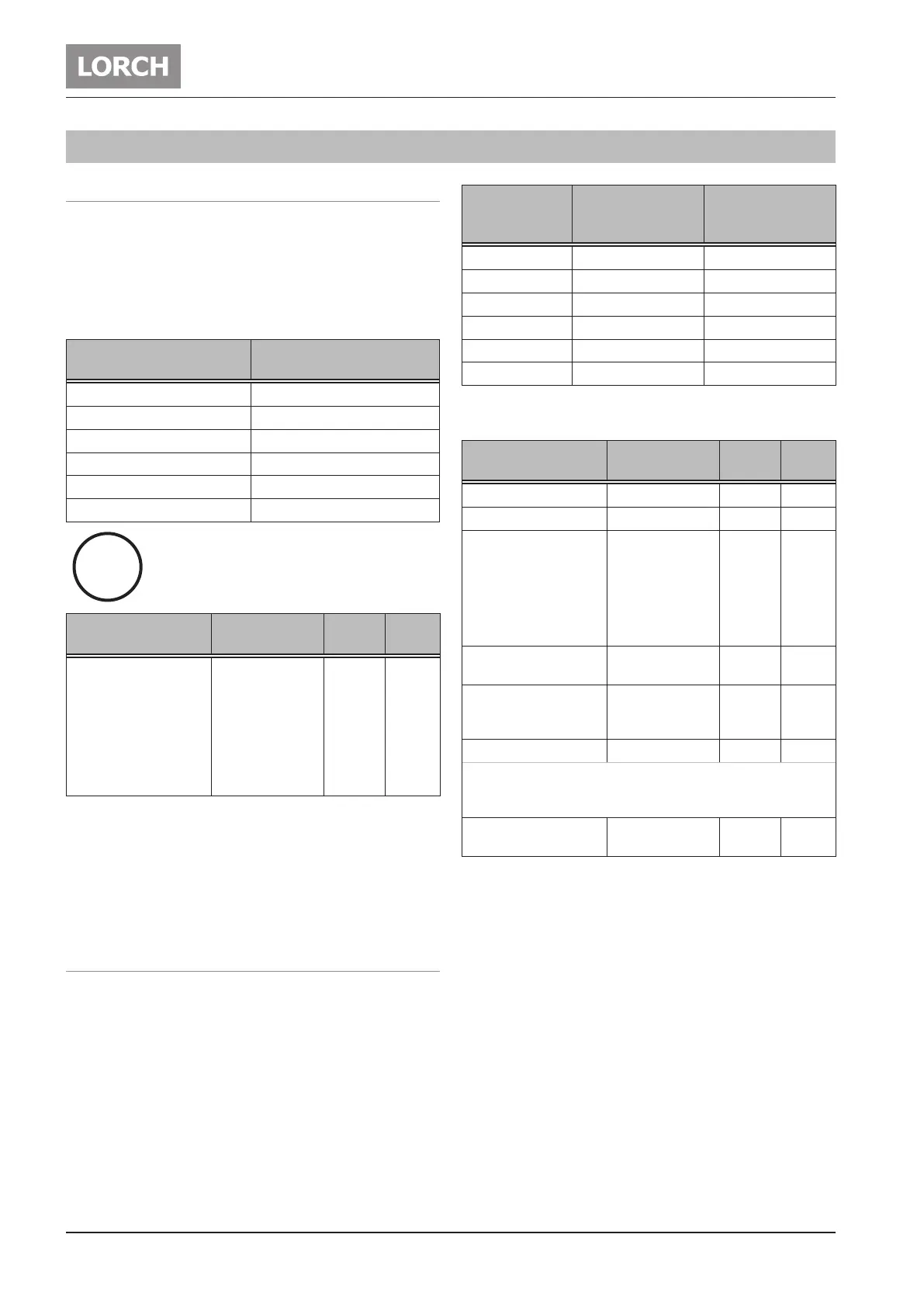

Electrode

diameter [mm]

Recommended

current intensity

DC [A]

Recommended

current intensity

AC [A]

1,0 3 - 40 5 - 30*

1,6 15 - 130 20 - 90*

2,0 45 - 180 45 - 135*

2,4 70 - 240 70 - 180*

3,2 140 - 320 130 - 250*

4,0 220 - 450 200 - 320*

*) Depending on the type of electrode and AC-Balance param-

eter setting

Parameter Range

Factory

setting

LED/

Code

Gas pre-ow time 0,1 - 10 sec. 0,1 35

Upslope 0 - 99 % 5 36

Main current I1

100 37

T 180 3 - 180 A

T 220 3 - 220 A

T 250 5 - 250 A

T 300 5 - 300 A

Second current I2

1 - 200 % of main

current

50 40

Pulse frequency (only for

pulse mode)

0,2 - 2000 Hz

(representation

0.2 - 2.0t)

5 39

Downslope 0 - 500 % 20 42

A synchronisation takes place in the DC pulse operating mode

with feed or control The current reduction always begins with I2

independent of the current status I1 or I2.

Gas post-ow time cor-

rection

20 - 500 % 100 43

Tab. 2: Main parameters

The factory setting values are optimised thanks to automatic

parameters.

You can use these factory settings unchanged for most weld-

ing jobs.

Further ne adjustment facilities can be found in Chapter „14.3

Secondary parameters“ on page 39.

i

Loading...

Loading...