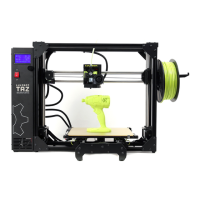

Maintaining Your 3D Printer

3.1 Overview

Little maintenance is required keep your LulzBot TAZ Workhorse 3D

printer running. Depending on your rate of use you will want to perform a

quick check of your printer every 2 to 4 weeks. The following maintenance

guidelines will keep your printer printing quality parts.

3.2 Smooth Rods

Wipe the smooth steel rods with a green scrub pad, clean cloth, or

paper towel. The linear bushings leave a solid lubricant that builds

up over time. Squeaking noises while the printer is in operation is

likely a sign that the smooth rods need to be cleaned. NOTE: Never

apply any lubricant or cleaning agent to the smooth rods as

the bushings are self-lubricating.

3.3 PEI Print Surface

The PEI print surface is the key to well-balanced part adhesion and release.

While long-lived, it will need to be replaced periodically and is considered

a consumable item. To clean the PEI print surface, wipe clean with

watered-down Isopropyl Alcohol 10:1 IPA to water ratio and a clean

cloth. If you encounter prints lifting from the PEI surface, use ne grit

sandpaper, typically 2000-2500 grit to clean the PEI print surface. We

do not recommend printing on bare glass, as it can lead to glass bed

damage or failure. Never use acetone to clean the PEI print surface as

doing so can damage the lm. You can nd our maintenance and guides

here: https://www.lulzbot.com/learn/tutorials

3.4 Hobbed Bolt

Filament is pulled through the extruder by a hobbed (or toothed) bolt.

After repeated use, the teeth of the hobbed bolt can become lled with

plastic. Using the dental pick from the printer kit, clean out the hobbed

bolt teeth. If an extruder jam ever occurs, remove the plastic lament

from the extruder and clean out the hobbed bolt.

76

Loading...

Loading...