214683 388 Revision A

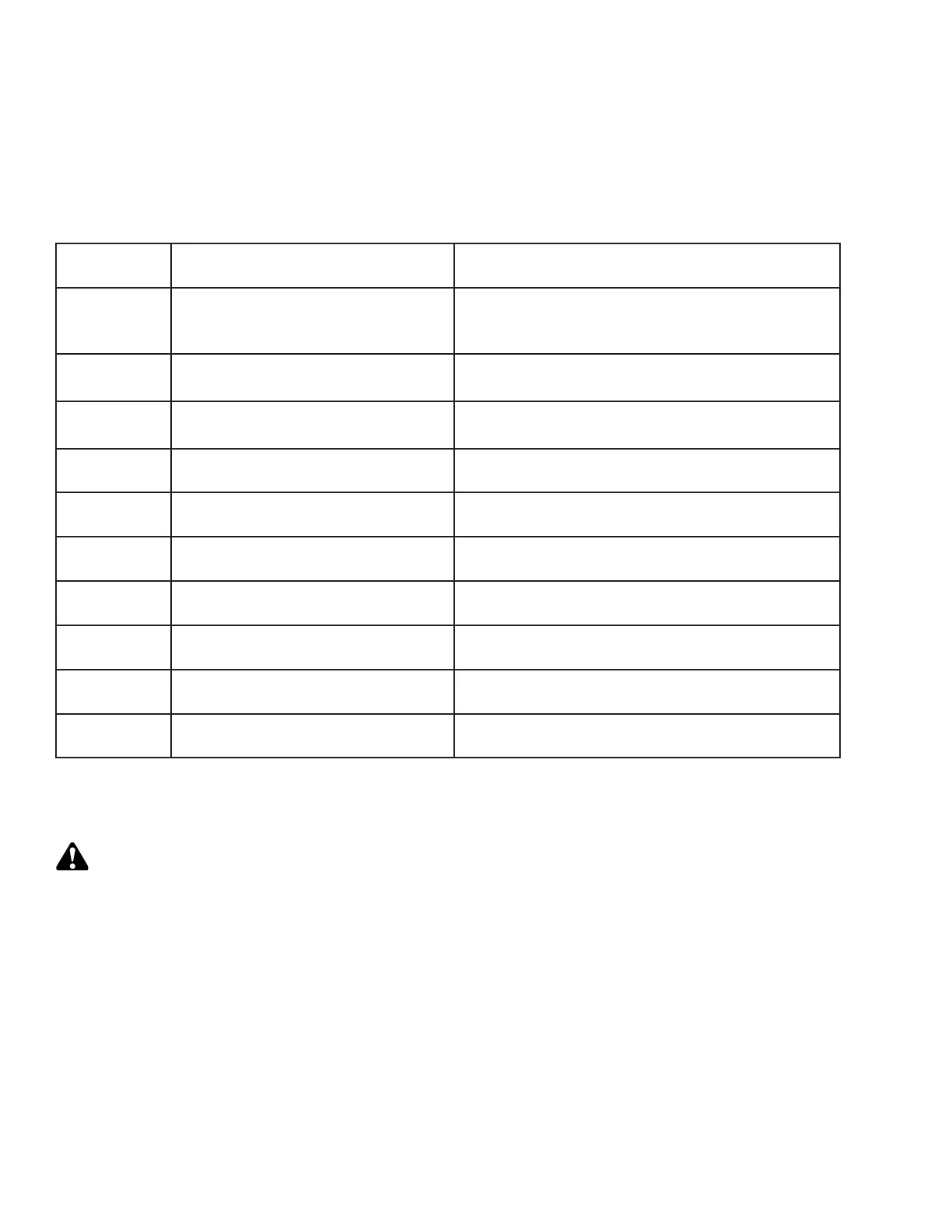

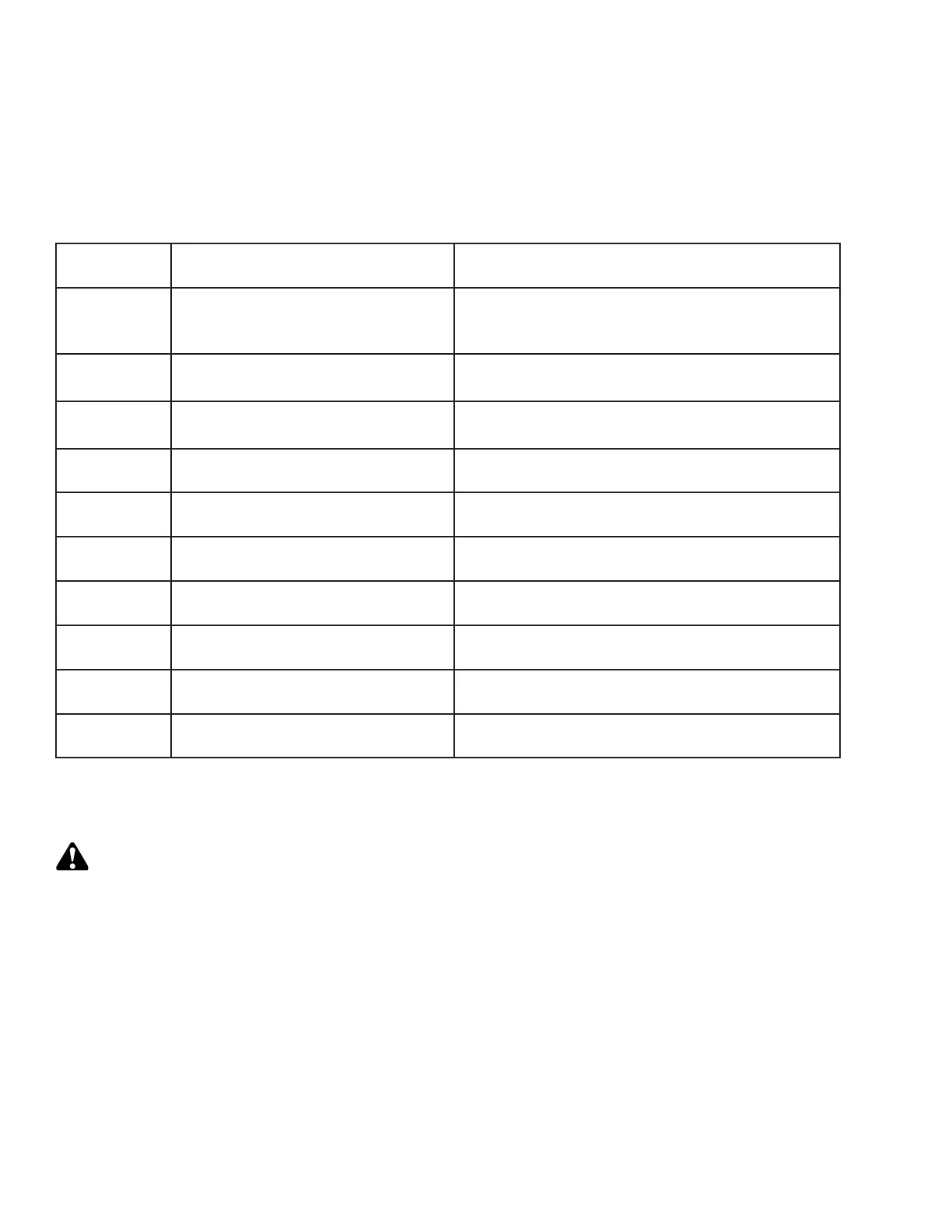

5.3.2 Break-In Inspection

Break-in inspection involves checking belts, fluids, and performing general machine inspections for loose hardware

or other areas of concern. Break-in inspections ensure that all components can operate for an extended period

without requiring service or replacement. The break-in period is the first 50 hours of operation after the machine’s

initial start up.

Inspection

Instance

Item

Refer to

5

Minutes

Check hydraulic oil level in reservoir

(check after first run-up and after the

hydraulic hoses have filled with oil).

5.4.1 Checking Oil Level in Hydraulic Reservoir, page

407

5

Hours

Check for loose hardware and tighten

to required torque.

8.1 Torque Specifications, page 577

5

Hours

Check knife drive belts tension (check

periodically for first 50 hours).

Checking and Tensioning Knife Drive Belts, page 464

10

Hours

Check auger drive chain tension. 5.7.2 Checking Auger Drive Chain Tension, page 421

10

Hours

Check knife drive box mounting bolts. Checking Mounting Bolts, page 455

50

Hours

Change float module gearbox oil. Changing Oil in Header Drive Gearbox, page 405

50

Hours

Change float module hydraulic oil filter. 5.4.4 Changing Oil Filter, page 410

50

Hours

Change knife drive box lubricant. Changing Oil in Knife Drive Box, page 461

50

Hours

Check gearbox chain tension.

5.6.5 Adjusting Gearbox Drive Chain Tension, page

418

50

Hours

Check deck height adjustment.

5.14.5 Adjusting Deck Height, page 492

5.3.3 Preseason Servicing

Perform the following procedures at the beginning of each operating season:

CAUTION

• Review this manual to refresh your memory on the safety and operating recommendations.

• Review all the safety decals and other decals on the header and note the hazard areas.

• Be sure all the shields and guards are properly installed and secured. Never alter or remove safety

equipment.

• Be sure you understand and have practiced safe use of all controls. Know the capacity and operating

characteristics of the machine.

• Ensure you have a first aid kit and fire extinguisher. Know where they are and how to use them.

1. Lubricate the machine completely. Refer to 5.3.6 Lubrication and Servicing, page 390.

2. Adjust the tension on the drive belts. Refer to Checking and Tensioning Knife Drive Belts, page 464.

MAINTENANCE AND SERVICING

Loading...

Loading...