214683 64 Revision A

3.7.3 Header Float

The header float system reduces the ground pressure at the cutterbar allowing the header to more easily follow the

ground and quickly respond to sudden ground contour changes or obstacles.

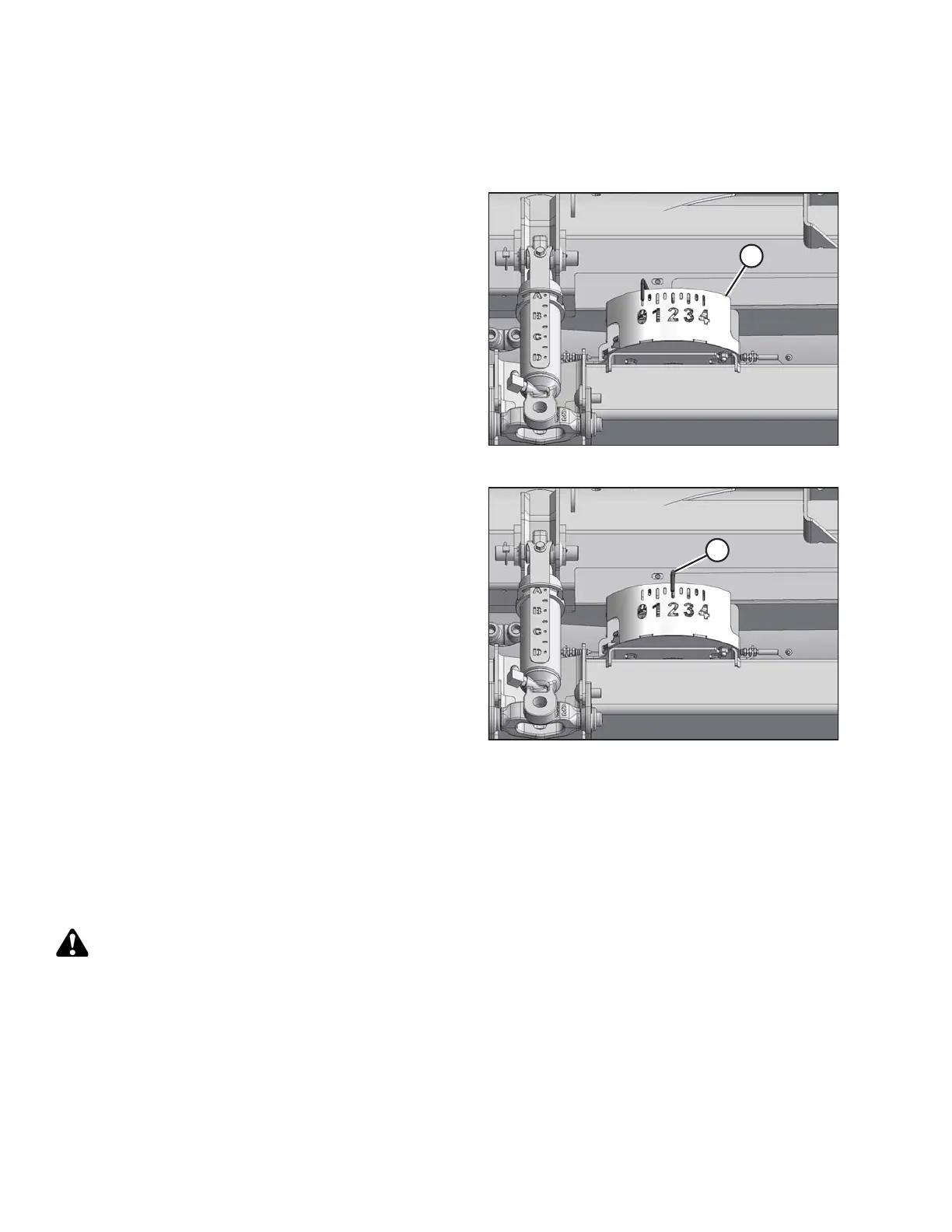

Figure 3.34: Float Indicator

Header float is indicated on the float indicator (A). Values 0

to 4 represent the force of the cutterbar on the ground with 0

being the minimum and 4 being the maximum.

The maximum force is determined by the tension on the

float module’s adjustable float springs. Float can be

changed to suit field and crop conditions and is dependent

on what options have been installed on the header. Refer to

Checking and Adjusting Header Float, page 64.

The FD1 Series combine header performs best with

minimum ground pressure under normal conditions.

Readjust the float if adding optional attachments to the

header that affect header weight.

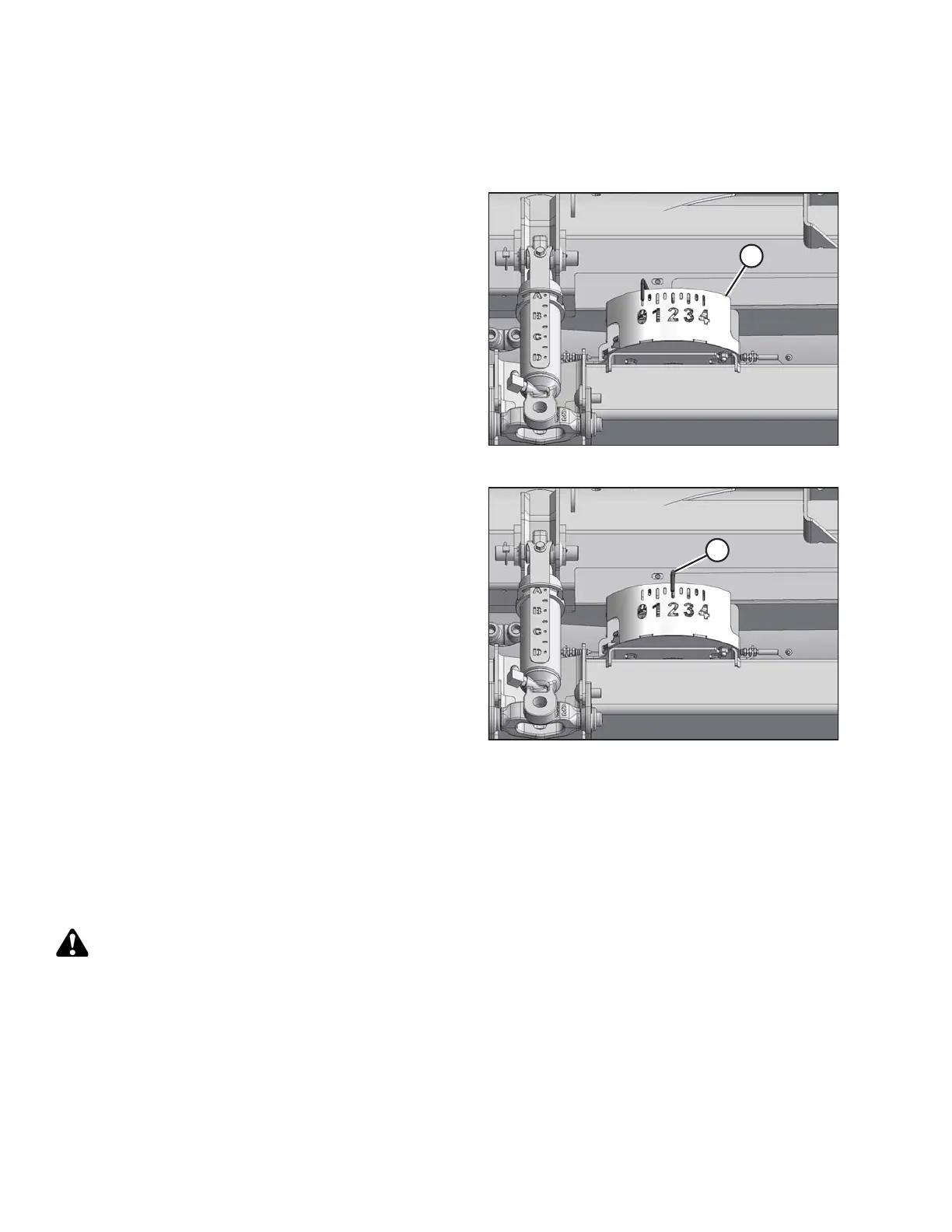

Figure 3.35: Cutting on the Ground

1. Set the float for cutting on the ground as follows:

a. Ensure the header float locks are disengaged.

Refer to Locking/Unlocking Header Float, page 69.

b. Lower feeder house using the combine header

controls until the float indicator (A) reaches the

desired float value (cutterbar ground force). Set the

float indicator initially to float value 2 and adjust as

necessary.

2. Set the float for cutting off the ground as follows:

a. Set up the stabilizer wheels. Refer to 3.7.1 Cutting

off the Ground, page 58.

b. Note the float value on the float indicator and

maintain this value during operation (disregard

minor fluctuations on the indicator).

Checking and Adjusting Header Float

The header is equipped with a suspension system that floats the header over the ground to compensate for ridges,

trenches, and other variations in ground contour. If the header float is not set properly, it may cause the cutterbar to

push into the ground or leave uncut crop. This procedure describes how to check header float and adjust to the

factory-recommended settings.

DANGER

To avoid bodily injury or death from unexpected start-up of machine, always stop engine and remove key

from ignition before leaving operator’s seat for any reason.

Use the following guidelines when adjusting float:

• Turn each adjustment bolt pair equally. Refer to Step 12, page 67, and repeat torque wrench reading procedure

on both sides of header.

OPERATION

Loading...

Loading...