Quattro DC Troubleshooting

107

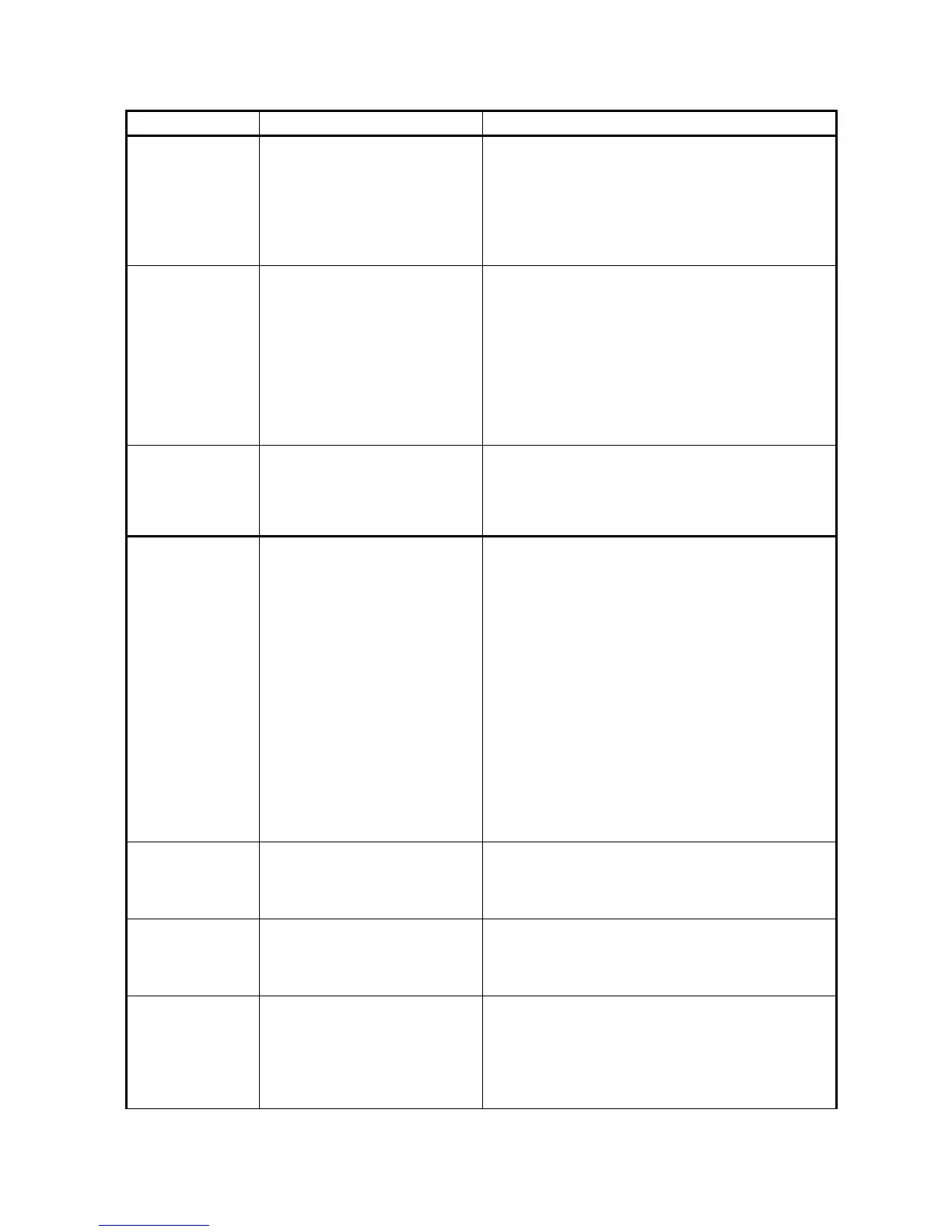

Name Description

Possible Causes & Corrective Action

Fld PWM Set Hi

The FLD CARRIER FRQ (A4)

is set too high for the type of

Field Module detected.

Check Parameter Settings

Verify FLD CARRIER FRQ (A4) is set at or

below 10kHz when a standard field module is

being use.

Note: Drive automatically detects the type of field

module, either Low Voltage Field Module or

Standard Field Module.

Fld Over Curr

If field current exceeds 250%

the fault is declared

immediately.

If field current exceeds 150%

for 0.5 seconds, the fault will be

declared.

If field current is less than

110% no fault will be declared.

Check Parameter Settings

Verify parameter settings for motor field

control

Check motor field and wiring

Check motor field and wiring for short circuits

Note: This fault cannot be reset, unit must be

powered down before fault will clear.

Full Fld Time

Drive was commanded to

provide Full Field current but

not told to Start for longer than

the time set in FULL FIELD

TIME (A1)

Incorrect Start Timing

Check for proper drive Start sequencing

signals

Verify FULL FIELD TIME (A1)

Hit Torque Limit

(alarm)

The drive is or was being

limited by the motor current

limit setting. This can limit

acceleration rates and cause

subsequent velocity tracking

errors.

Incorrect Wiring

Verify motor armature circuit wiring

Verify motor field current is correct

Drive and/or Motor is Undersized

Verify drive and/or motor sizing. May need a

larger capacity Drive and / or motor.

Check Parameter Settings

Check the torque limit parameter MTR

TORQUE LIMIT (A1)

Alarm sensitivity - TRQ LIM MSG DELAY (A1)

parameter determines the amount of time the

drive is in torque limit before the alarm

message is displayed.

Problem in the motor fields

Verify that the motor field coils are operating

correctly, check DC resistance and perform an

AC drop test to verify.

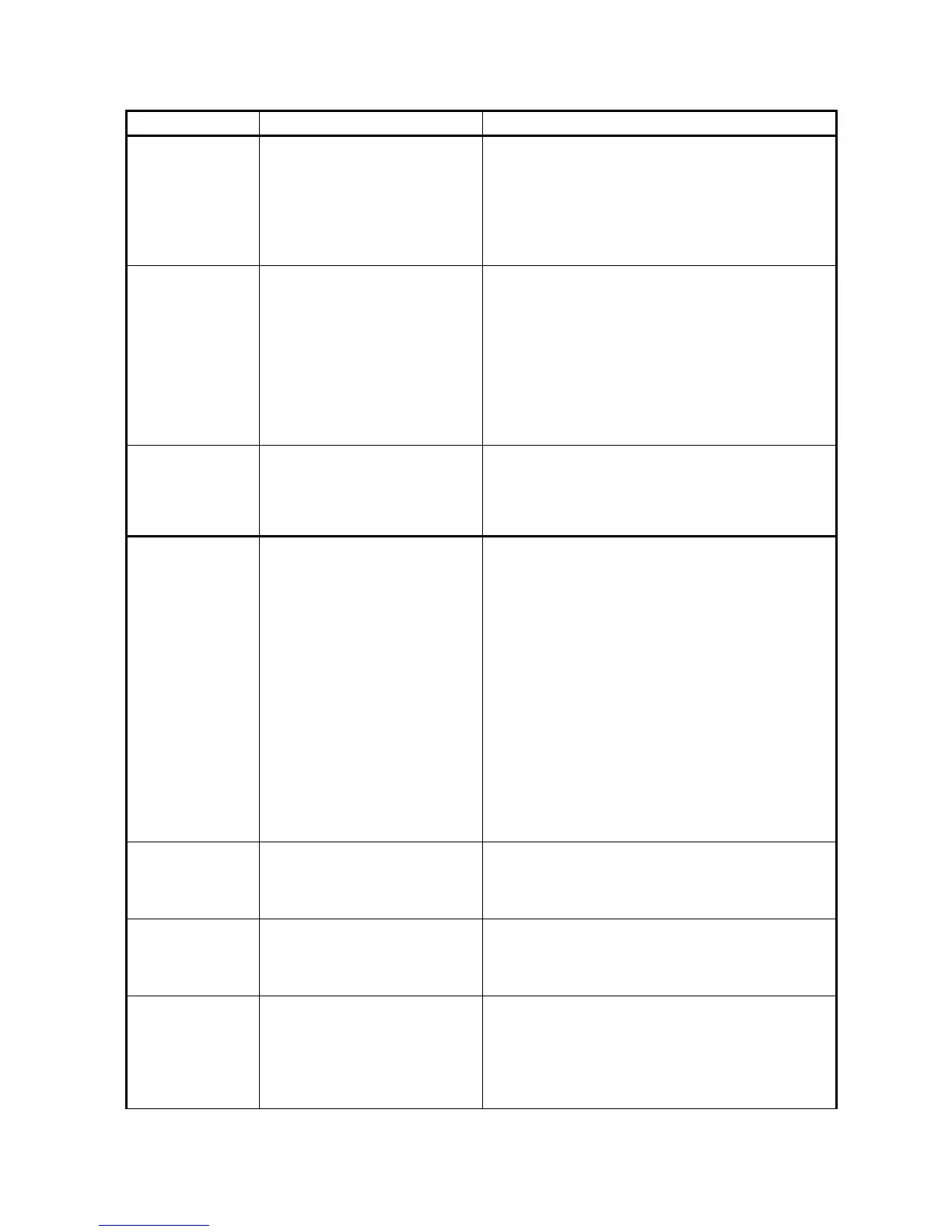

HW/SW

Mismatch

Line side software is installed

in the motor side control board

and cube id is for motor side

Mismatching cube ids vs. software

Replace A2 board with correct software for

board location or program correct software

into Motor Side Board

Invalid

Checksum

(operator serial

link error)

The operator received four

consecutive invalid messages.

Noise or Bad Connector Connection

Remove and re-seat the operator in its cradle.

If re-occurs, the operator or the drive’s control

board may need to be replaced.

IP Comm

A fault has occurred in the

communications channel

between the Line side and

Motor side processors. This

was detected on the motor

side.

Communication problem

Reset drive

Verify Line Side software and Motor Side

software is compatible

If re-occurs, replace Main Processor PCBs

Replace the low voltage power supply

Loading...

Loading...