25

15. Then take the bag from the lower side

of the tunnel (left or right) and insert it

over the rack in same proportion (50%),

repeat this task in the other side. Then

locate the central part of the bag 50%

over the central section of the rack.

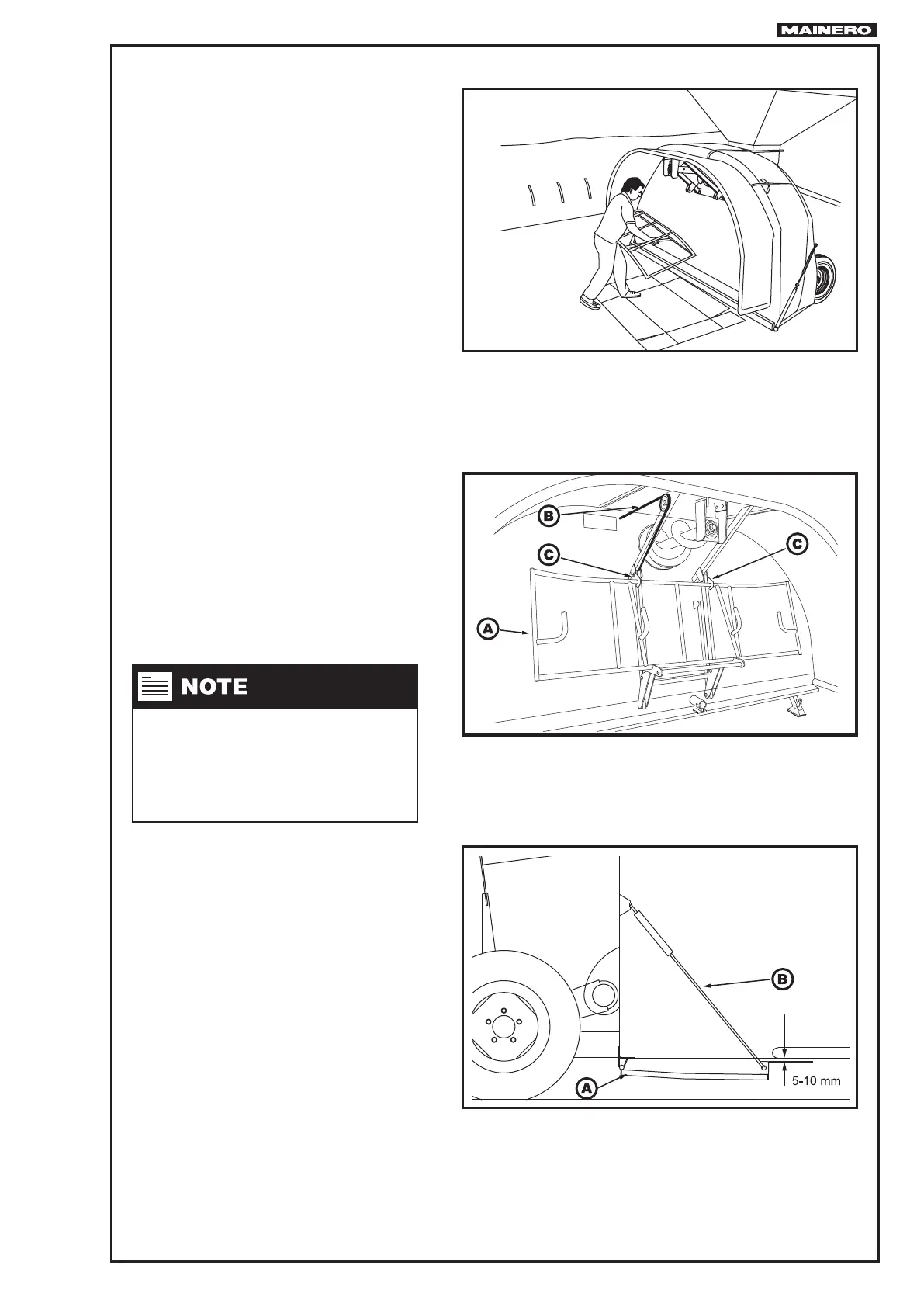

16.Continue displacing the bag until

mount it totally upon the tunnel and the

rack Fig. 37 (make it ow until the end

of the tunnel).

17.Lower the parallelogram “A” Fig. 38,

until be supported in the tunnel, loosing

all the cable “B”, turn it 90º upwards

and put the safety locks “C”.

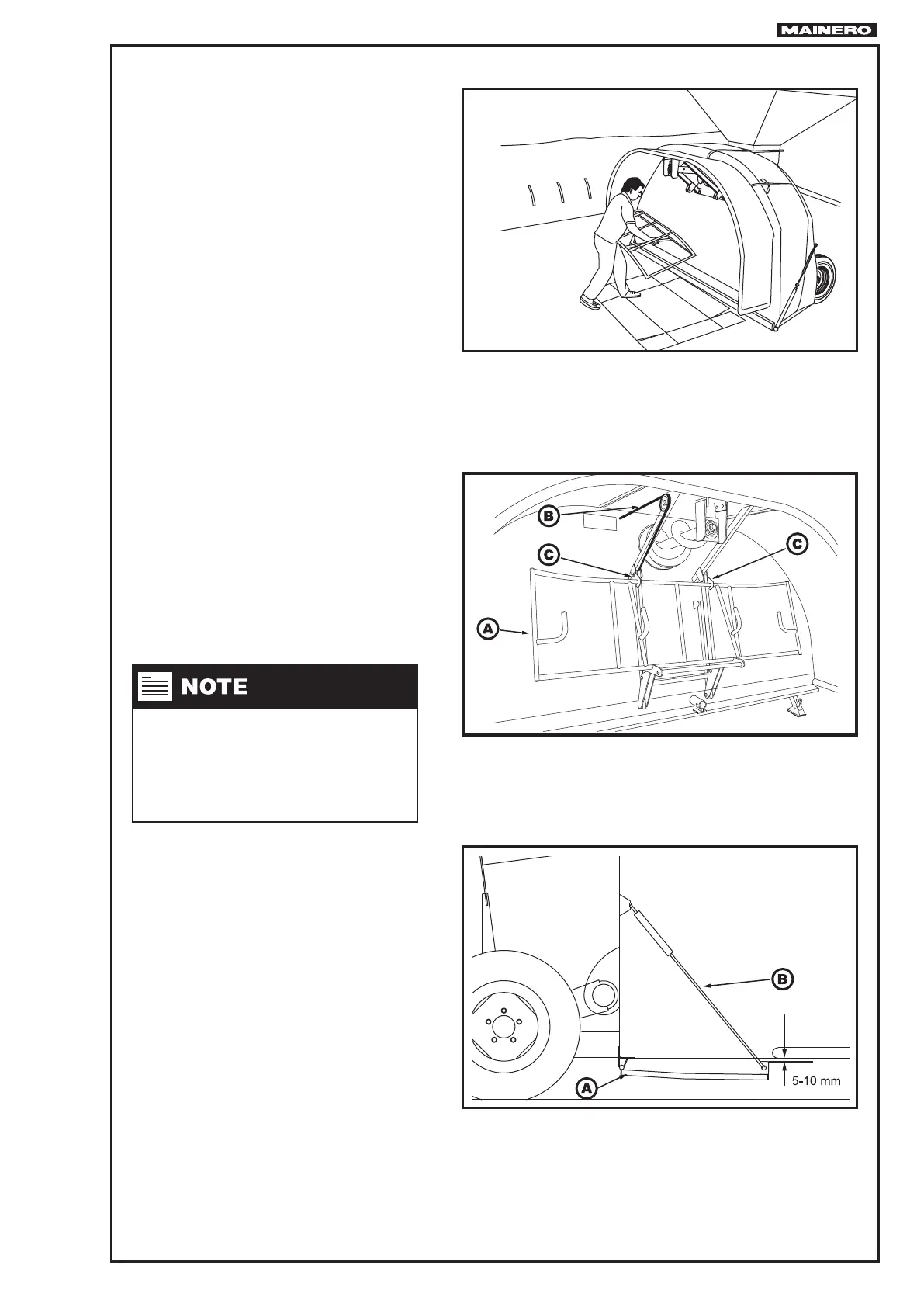

18. Lower the machine to a 50% of the

hydraulic cylinder stroke. Then raise

the rack “A” Fig. 39 and hitch it onto

the side adjusters “B”. Regulate the

openning of the rack and the chassis

to a value“5 – 10 mm”( 0.2 - 0.4 in),

never less thjat the grain size that is

been bagged.

19. Take off all the security belts “B” Fig

35, that maintain the folds armed.

20. Start taking out the bag from the outer

fold, in its entire periphery, in equal pro-

portion. From above toward the sides

and nally in the rack, aproximately 1

m (3 ft. maximum) out of the tunnel.

Ipesasilo

Ipesasilo

Ipesasilo

Ipesasilo

If it exists a passage of grain from the

lling tunnel to the front side of the

machine, it is because the opening

between the rack and the chassis is

too big, it must be reduced.

FIG.37

FIG.38

FIG.39

Loading...

Loading...