35

BRAKE CIRCUIT

• The working pressure can be adjusted between the following values:

MINIMUM . . . . . . . . . . 4903 kPa (49.033 bar) (50 kg./cm

2

) (735 PSI)

MAXIMUM . . . . . . . . . 14709.9 kPa (147.099 bar) (150 kg./cm

2

) (2200 PSI)

• MANOMETER: indicate the brake circuit pressure, which limits the grade of advance of the machine,

when the material enters the bag.

• CHANGE OF THE COMPACTATION PRESSURE: do it this way:

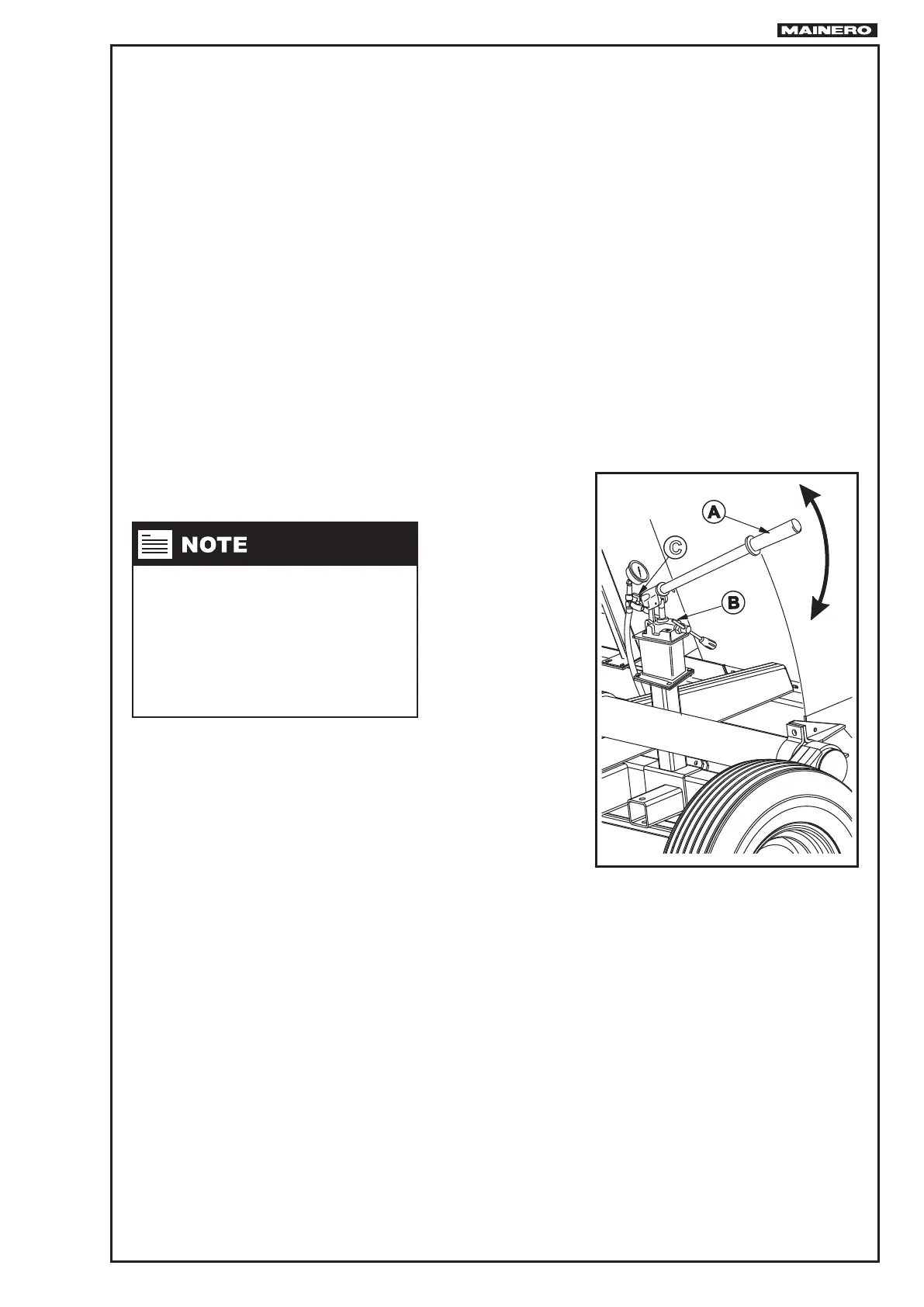

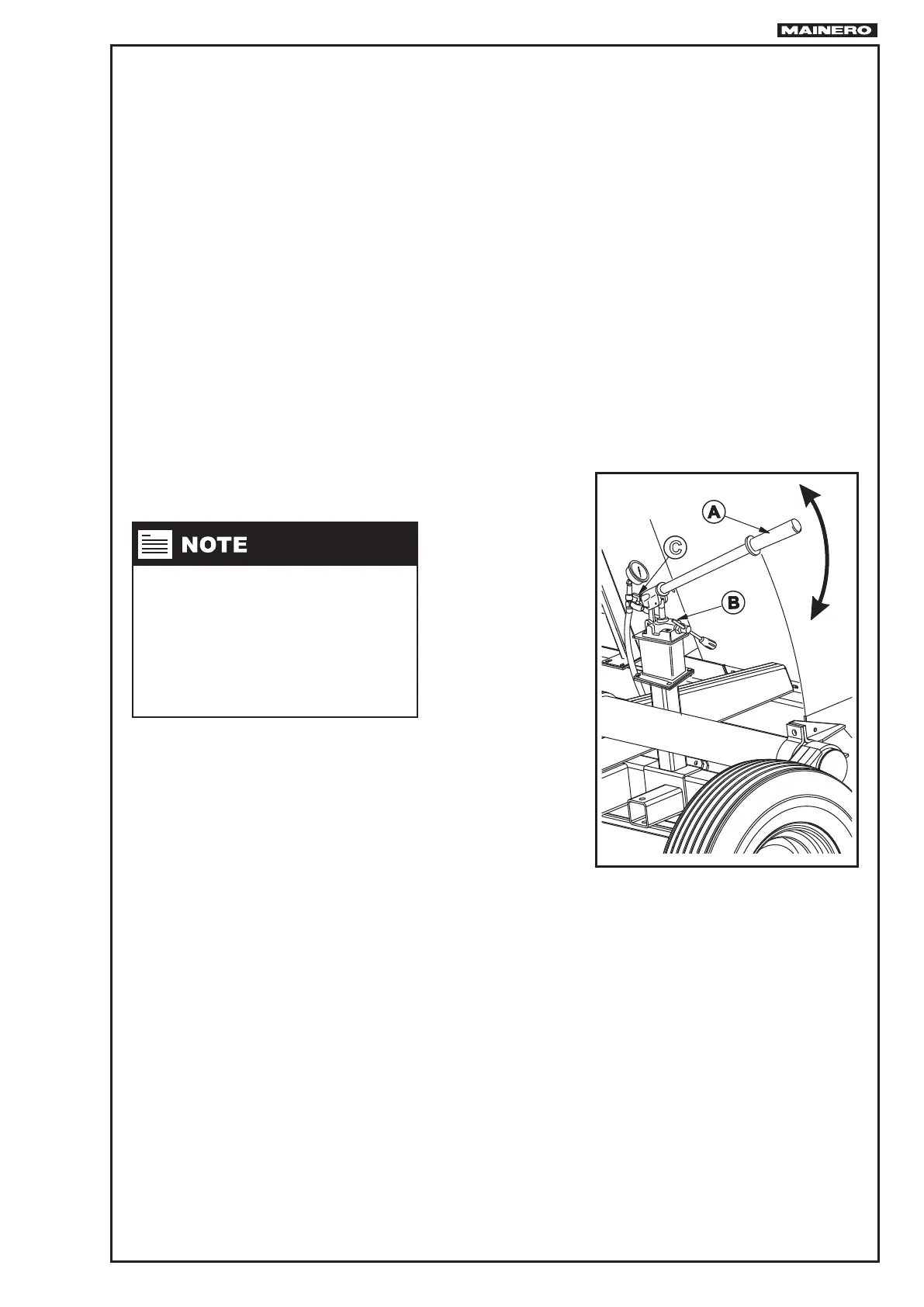

1. Open closing valve “C” Fig. 53.

2. Insert the lever “A” Fig. 53 in the pump.

3. Working the lever “A” up and down is possible increase the compactation pressure.

4. Repeat this operation until obtaining the wanted pressure.

5. Close valve “C”.

Verify in the compaction variation obtai-

ned, for each material.

It is an indispensable condition that, du-

ring the bag lling, not to produce a fall on

the compacting pressure, that will result

in poorly compacted or odd bags.

• If eventualli the gauge DO NOT INDICATE PRESSURE, it can be damaged or the circuit and deposit

liquid is in bad condition. Ask the technical service of your MAINERO dealer.

• Only use MAXIMUM PRESSURE in special cases. Do not use, for normal working use because it will

cause futible over efforts, premature damages in the machine and possible breaking of the bag.

• If the brake disks have been rusted by lack of use or for being outdoor, they must be cleaned with a ne

sand paper, to get the system to work correctly.

• Do not open the valve “B”, the com-

pacting pressure falls to zero.

• Do not increase the compacting

pressure ABRUPTLY, it must be pro-

gresive, maximum 10 - 15 kg/cm²

(140 - 210 psi) every time.

FIG.53

C

Loading...

Loading...