REPLACE Alternator belt

IMPORTANT

Check the belt tension again after the first 20 hours of operation.

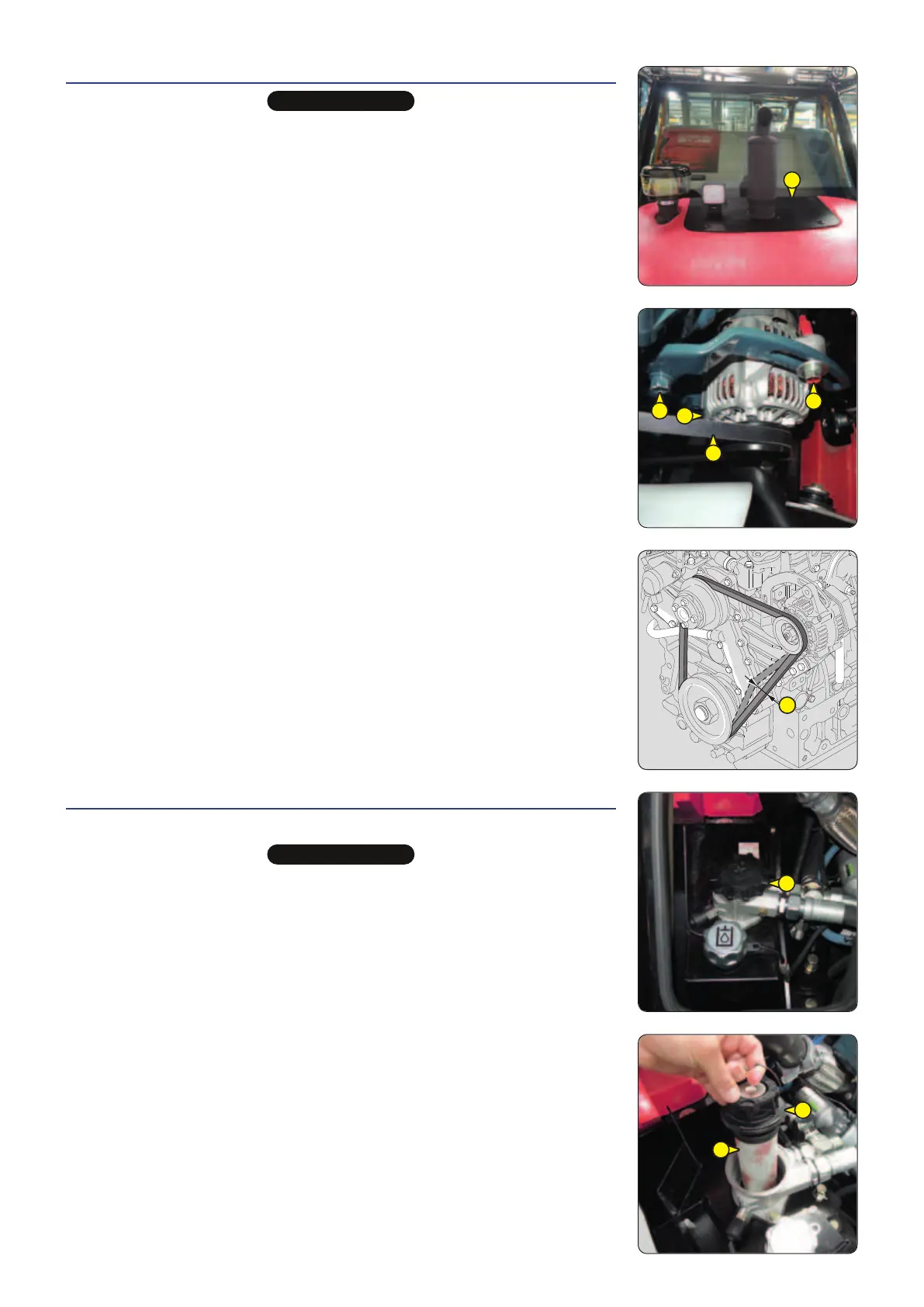

- Remove the access panel 1.

- Loosen screws2 by two to three thread turns.

- Swivel the alternator assembly so as to free the belt 3.

NOTE: Take the opportunity provided by the removal of the belt to check that the

pulleys and bearings are working correctly (noise, friction, play, etc.).

- Remove the belt and replace with a new one (

FILTER CARTRIDGES AND BELTS).

- Ensure that it is properly seated in the grooves of each pulley.

- Adjust the belt tension between the crankshaft and alternator pulleys.

- Swivel the alternator assembly so as to obtain the required belt tension.

- Under normal pressure applied by the thumb (98 N), belt movement A should be

between 10 and 12mm.

- Retighten the screws 2.

REPLACE Hydraulic return oil filter cartridge

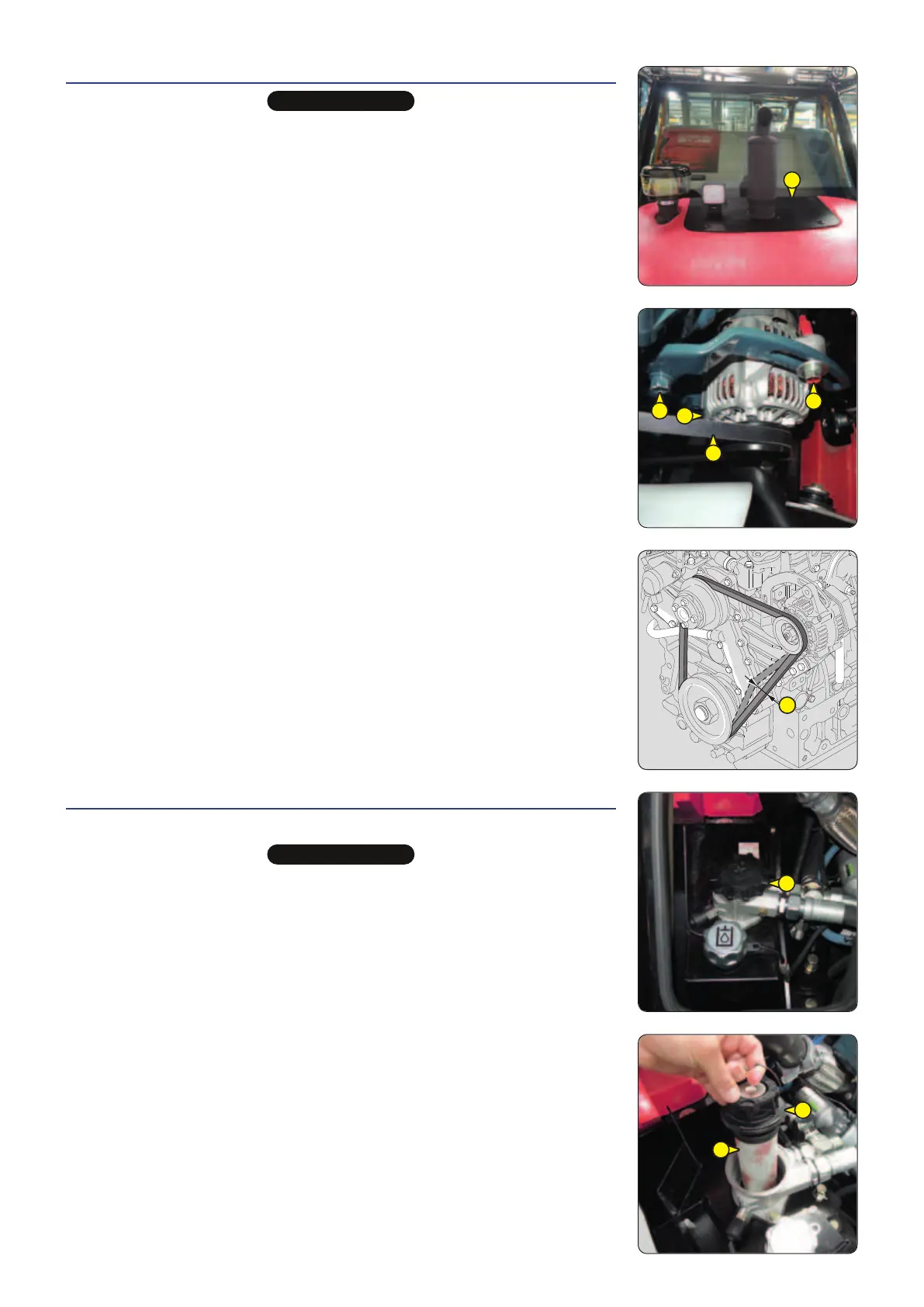

Place the lift truck on level ground with the engine stopped.

IMPORTANT

Do not operate the lift truck without the cartridge in place, as this would immediately damage the hydraulic

transmission system, the pump and the hydrostatic wheel motors.

- Release the pressure from the circuits by operating the hydraulic controls.

- Open the engine cover (2-DESCRIPTION-INSTRUMENTS AND CONTROLS).

- Carefully clean the outside of the filter and the area surrounding it

- Unscrew the plug 1 with a wrench.

- Remove the hydraulic oil filter cartridge 2 from the filter head 3 and replace it with

a new one (FILTER CARTRIDGES AND BELTS).

- Refit the unit.

3 - 23

A

1

2

2

2

3

2

3

1

647837 M1 (A052020)

MC 18-2/18-4 D K ST5 S1

Loading...

Loading...