Â

50H- WEEKLY SERVICE OR EVERY50 HOURS OF SERVICE

CHECK Alternator belt tension

IMPORTANT

If the compressor belt has to be changed, check the tension again after the first 20 hours of operation.

- Remove the access panel 1.

- Check the belt for signs of wear and cracks and change if necessary (FILTER

CARTRIDGES AND BELTS).

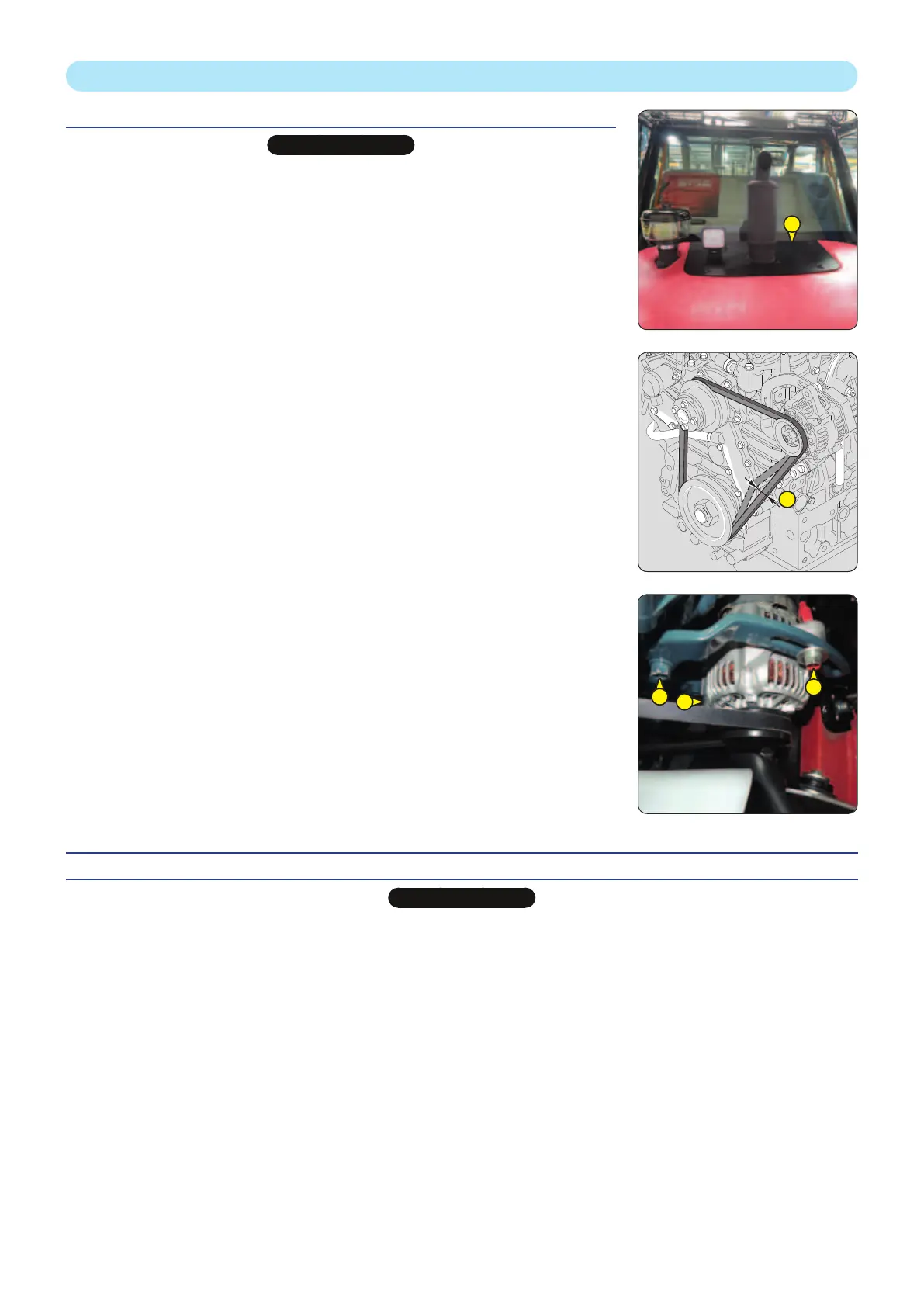

- Check the belt tension between the crankshaft and alternator pulleys.

- Under normal pressure applied by the thumb (98 N), belt movement A should be

between 10 and 12mm.

- Carry out adjustments if necessary.

- Loosen screws2 by two to three thread turns.

- Swivel the alternator assembly so as to obtain the required belt tension.

- Retighten the screws 2.

CHECK Tyre pressures

CHECK Wheel nut tightening

IMPORTANT

Check that the air hose is correctly connected to the tyre valve before inflating and keep all persons at a distance during inflation.

Inflate to the recommended tyre pressures.

- Check the wheel nut tightening. Non-compliance with this instruction can lead to deterioration and breakage of the

wheel bolts and distortion of the wheels.

- Check and restore tyre pressures if necessary (2-DESCRIPTION: TYRES).

NOTE: There is an OPTIONAL wheel toolkit.

3 - 14

A

1

2

2

2

647837 M1 (A052020)

MC 18-2/18-4 D K ST5 S1

Loading...

Loading...