Grove Published 11-10-2014, Control # 524-00 8-37

RT880E SERVICE MANUAL UNDERCARRIAGE

3. Remove the cylinder cap.

4. Place a jack capable of supporting the weight of the jack

cylinder at the base of the cylinder barrel. Jack up the

cylinder just enough to relieve any pressure on the cylin-

der retaining pin.

5. Remove the cotter pins securing the cylinder retaining

pin and remove the cylinder retaining pin and cylinder

cap retaining bracket.

6. Jack the jack cylinder up just enough to insert the retain-

ing pin back into the cylinder. Insert the retaining pin into

the lugs on the cylinder and secure the pin in place with

the cotter pins.

7. Fasten a nylon strap onto the cylinder retaining pin and

use an adequate lifting device to lift the jack cylinder out

of the tube on the beam assembly.

Installation

1. Apply grease (EPMPG) to the ID of the jack cylinder

support tube.

2. If removed, install wear ring in groove in bottom of sup-

port tube and in groove at top on jack cylinder.

3. Place a jack beneath the cylinder tube on the outrigger

beam. Using the same method as described under

Removal, lower the jack cylinder into the cylinder tube

on the outrigger beam until the retaining pin is just above

the tube. Position the jack so that it will support the cylin-

der in this position. Remove the lifting device from the

cylinder.

4. Remove the retaining pin and cotter pins from the cylin-

der.

5. Lower the jack until the holes in the cylinder rod align

with the holes in the outrigger beam.

6. Apply anti-seeze compound to the retaining pin. Secure

the cylinder and cylinder cap retaining bracket to the

support tube with the retaining pin and cotter pins.

7. Install the cylinder cap.

8. Install the fittings in the cylinder ports and connect the

hoses as tagged during removal.

Functional Check

1. Activate the hydraulic system.

2. Extend and retract the jack cylinder.

3. Check for smooth operation of the cylinder.

4. Check all hydraulic connections and hoses for evidence

of leakage.

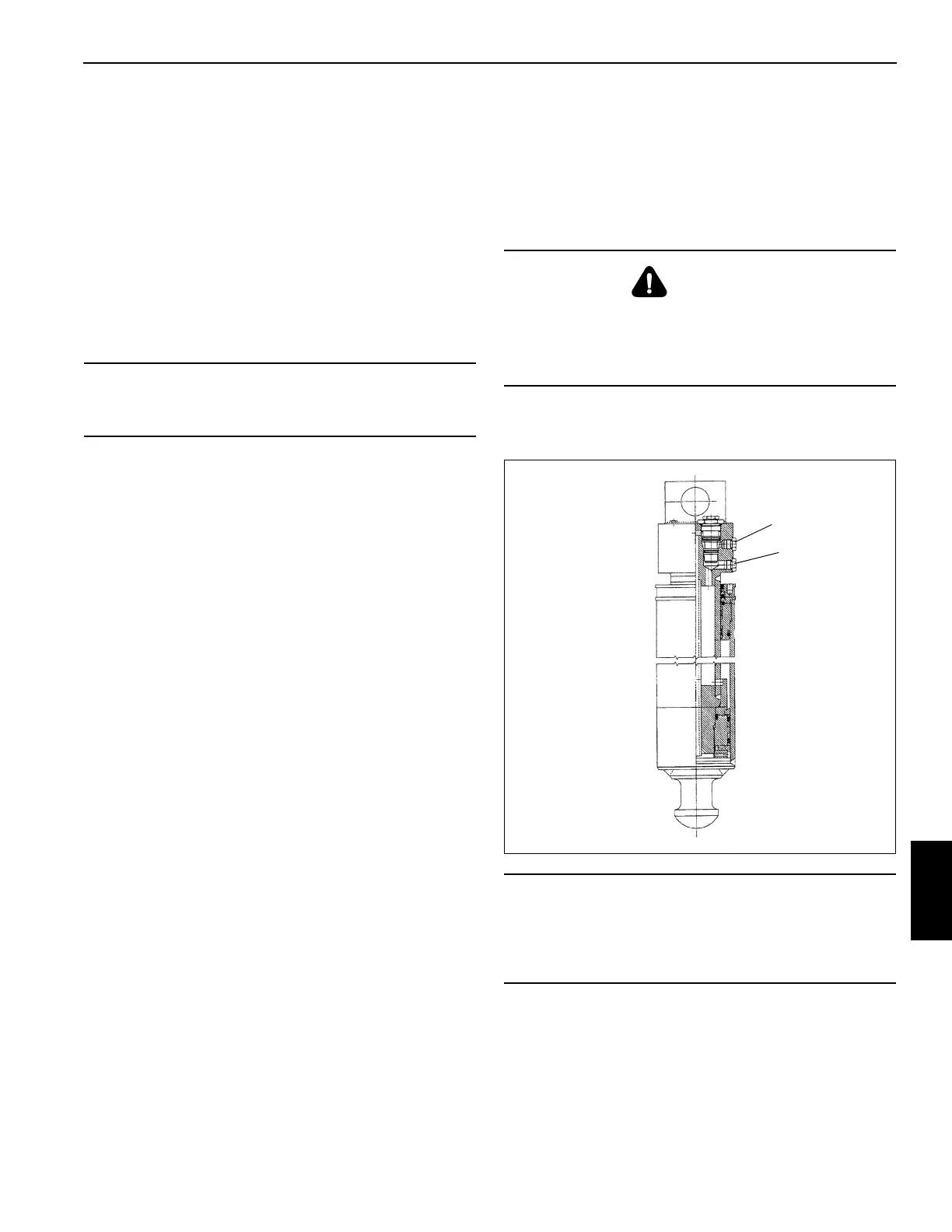

Outrigger Jack Cylinder Internal Leak Test

Use the following procedure to troubleshoot and diagnose an

internal leak, a leaking pilot operated check valve or a

thermal contraction on an outrigger jack cylinder.

Checking Cylinder for Internal Piston Seal Leak

1. Fully extend and set the outriggers.

2. Remove the rod side cylinder hose from the suspected

leaking jack cylinder (see Figure 8-36). Oil will flow until

the cavity in the cylinder port block empties. Once the

port block cavity empties, oil should stop flowing from

the rod side port.

Check for the following conditions:

CAUTION

Use a nylon strap to remove the cylinder. This will ensure

the retaining pin is not damaged.

DANGER

Perform the following procedures with the crane

positioned on a firm level surface with outriggers fully

extended and set, and the crane in the travel position

Remove hoses from one cylinder at a time.

CAUTION

When performing step number 2, remove hose to adapter

connection slowly. Trapped pressure may exit between

the outrigger cylinder and the work port pilot operated

check valves in the outrigger selector valve.

FIGURE 8-36

Piston Port

Rod Port

6432

Loading...

Loading...