GROVE Published 10-21-2010, Control# 198-04 4-49

5540F/YB5515 SERVICE MANUAL HYDRAULIC SYSTEM

Installation

1. Position the valve assembly on the mounting plate and

secure with three bolts, washers and nuts.

2. Connect the hydraulic lines to the control valve.

3. Start the engine and release the air captured in the

hydraulic lines, by operating each hydraulic function

several times in each direction.

4. Check for leaks and fill the hydraulic reservoir if

required.

Swing Motor

Removal

1. Shut off the engine and release any hydraulic pressure

in the swing motor circuit by moving the control lever in

both directions.

2. Before disconnecting the hydraulic lines, clean the port

area of the swing motor thoroughly. Disconnect the

hydraulic lines from the swing motor. Put caps and plugs

on the lines and motor ports to keep dirt out.

3. Remove the two mounting bolts from the swing motor.

Remove the swing motor.

Disassembly

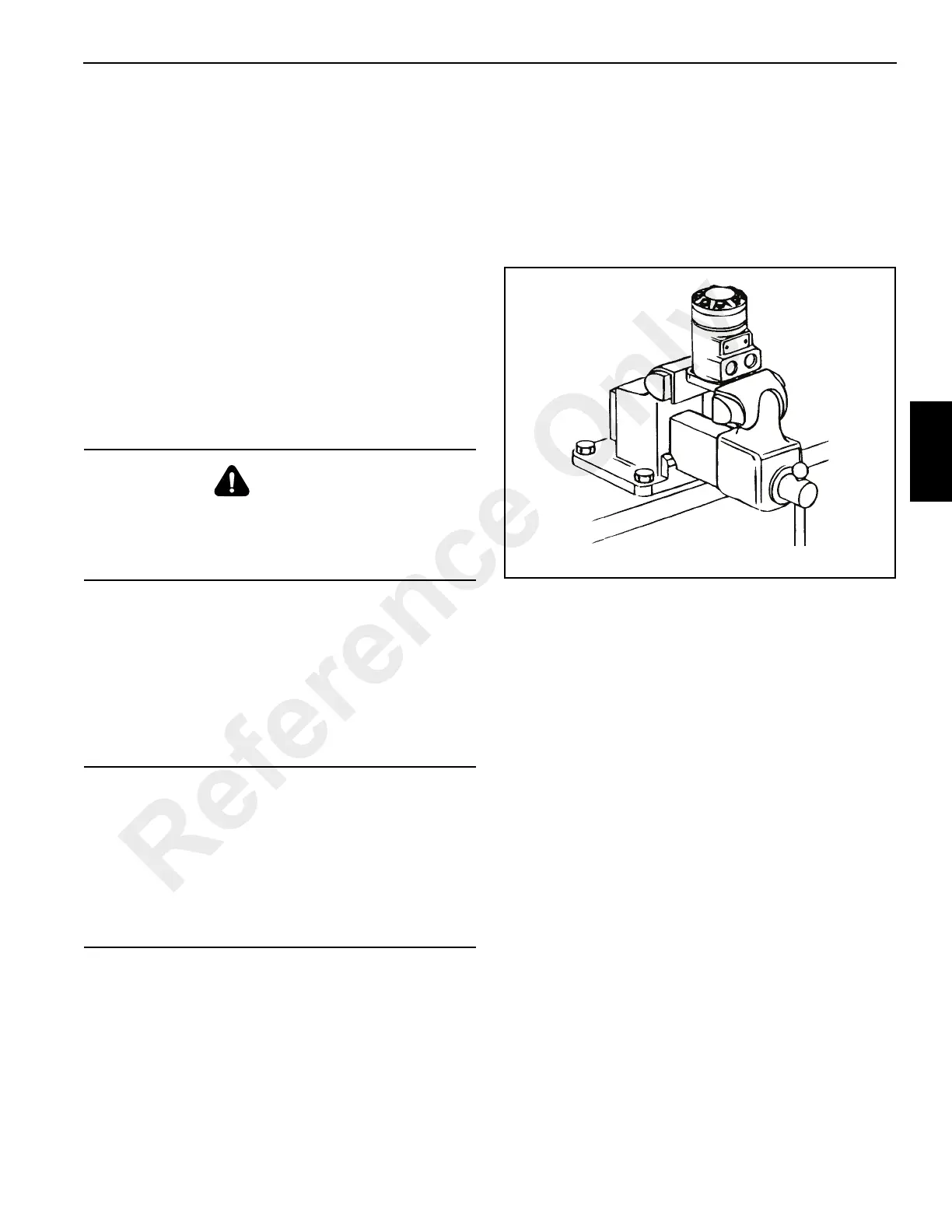

1. Place the motor in a vice and clamp across the edges of

the flange Figure 4-48 with the output shaft facing down.

When clamping use protective devices on the jaws, such

as soft jaws, pieces of rubber or wood.

NOTE: Although not all drawings show the motor in a vice,

it is recommended that you keep the motor in the

vice during disassembly and assembly. Follow the

clamping procedure explained in Step 1.

2. Remove seven capscrews 19 Figure 4-49 and seal

washers 18.

3. Remove end cap 17. Remove and discard seal 13 from

the end cap.

4. Remove gerotor 16. Remove and discard seal 13 from

the gerotor.

5. Remove drive shaft 14.

6. Remove spacer plate 15.

7. Remove seal 13 from housing 10.

8. Remove output shaft 9 from housing 10.

9. Remove needle thrust bearing 8 from shaft or housing.

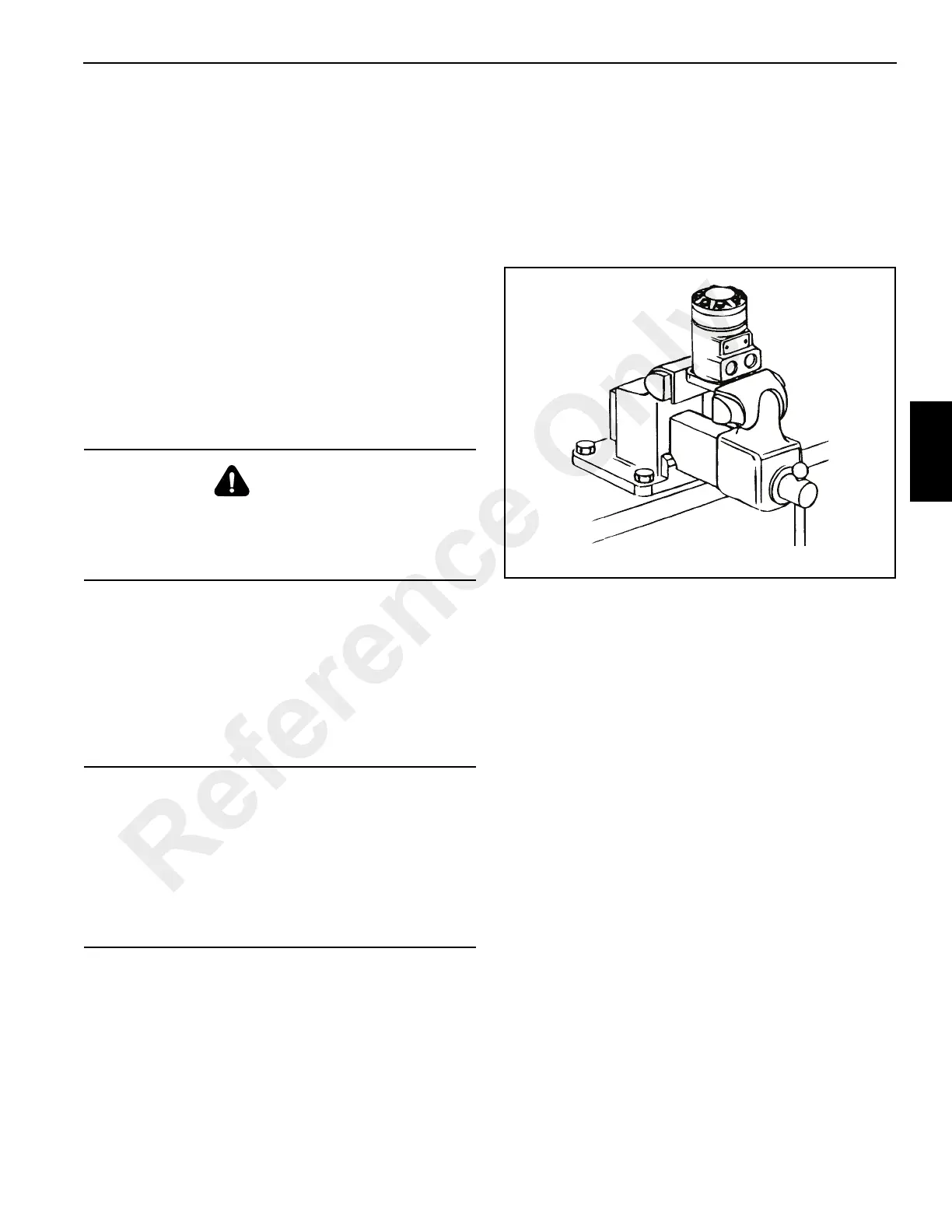

10. Reposition the motor in the vice. Clamp across ports

Figure 4-50. DO NOT clamp on housing. Excessive

clamping pressure on side of housing causes distortion.

CAUTION

The swing motor can only be reached from under the

machine. Shut off the engine and remove the ignition key

to prevent accidental starting and moving of the crane

while working under it. Block all tires.

CAUTION

Cleanliness is extremely important when repairing the

swing motor. Work in a clean area. Plug the ports then use

a wire brush to remove foreign material and debris from

around the external joints of the motor. Check the shaft

and key slot, remove all nicks, burrs or sharp edges that

might damage seals during installation. Before starting

the disassembly procedures, drain any remaining oil from

inside the motor.

Reference Only

Loading...

Loading...