5540F/YB5515 SERVICE MANUAL

9-16 Published 10-21-2010, Control# 198-04

hydraulic system. Keep all parts free of contaminants,

dirt and debris.

NOTE: Coat the surfaces indicated Figure 9-28 with a

Lithium Base, E.P. No. 2 bearing grease or

equivalent.

19. Install new lining 25 Figure 9-28 in housing 26 using new

bushings 24 and pan head screws 27. Tighten the

screws to 22-28 lb-in. (2,5 - 3,3 Nm).

20. Install new lining 20 on piston 19 using new flat head

screws 21. Tighten screws to a torque of 30-40 lb-in (3,4

- 4,5 Nm). Install new o-rings 18 on piston 19 and insert

lining and piston assembly 22 into housing 26 bore.

21. Carefully install two new seals 28 in housing 26. Be sure

to install the seals the same direction as they were

removed.

22. Install bleed screw 30. Tighten to a torque of 9-15 lb-ft

(12,2 - 20,3 Nm).

23. Install new o-rings 13 and 16 and new backup rings 14

and 17 on piston 15. Be sure they are installed in the

correct order.

24. Install piston 15 into housing 26 bore. Be sure piston is

installed in the correct direction. Be careful not to pinch

the o-rings on the inlet ports.

25. Install new backup ring 10 and new o-ring 11 on piston 9.

Be sure they are installed in the proper order. Install

push rod 12 in bore of piston 9. Install piston into

housing 26 bore.

26. Fully lubricate the threads of adjusting screw 7 and lock

nut 9 and install into cover 3.

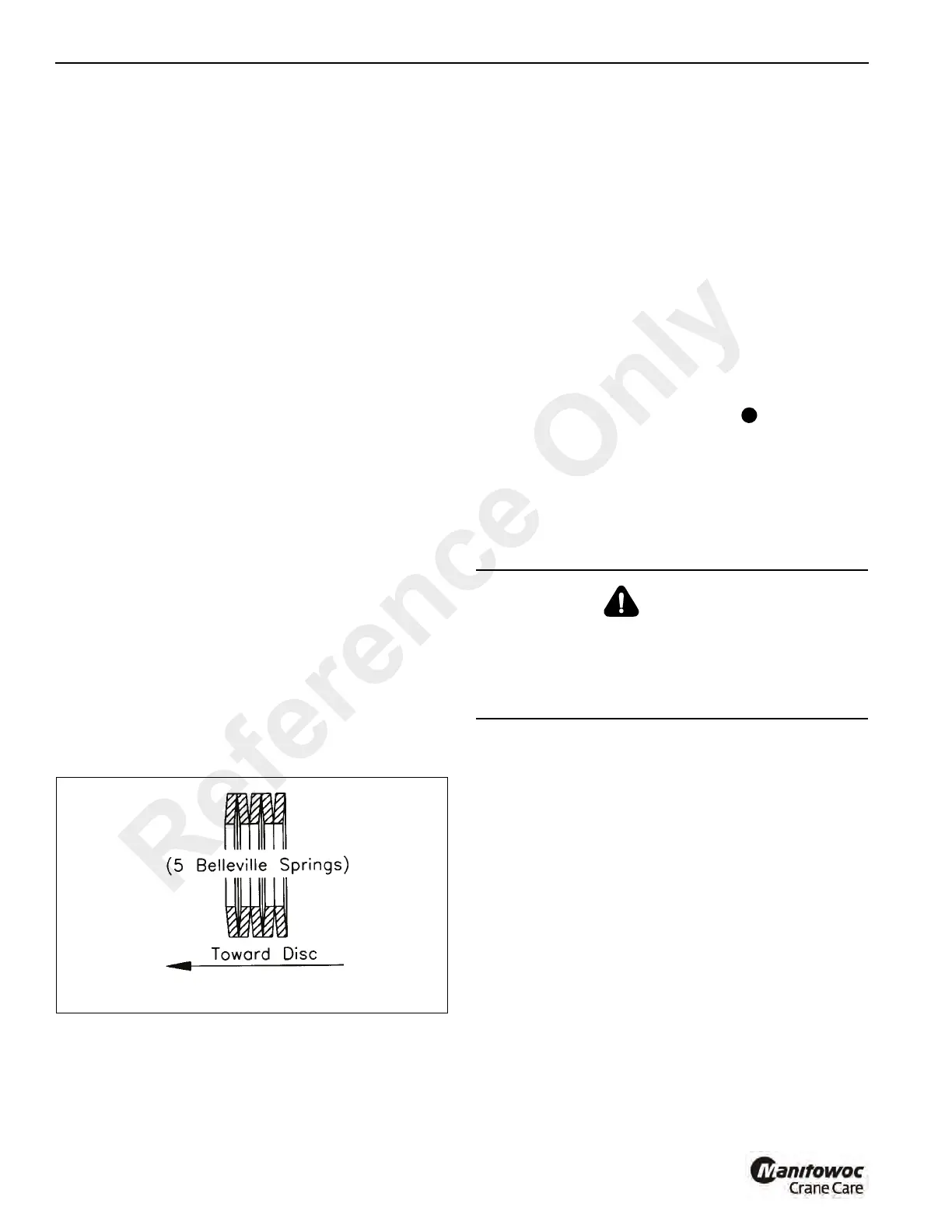

27. Install washer 6, if used, and new belleville springs 5

over end of piston 9. Follow the

stacking sequence

Figu

re 9-30.

28. Install new seal 4 in cover 3. Be sure inside of cover is

coated with grease.

29. Install new gasket 23, cover 3, lockwashers 2 and

capscrews 1. Tighten the screws evenly in the order of

A, B, C and D Figure 9-29. When installed, tighten each

screw to a torque of 22-27 lb-ft (29,8 - 36,6 Nm).

30. Assemble the brake assembly onto the mounting

bracket 31.

31. Install the parking brake assembly onto the frame of the

crane.

32. Attach the hydraulic hose.

33. Adjust the lining clearance as described on page 9-6.

34. Open the accumulator needle valve and then bleed air

from the system as described on page 9-5.

Seal Kit Installation

The parking brake has a seal kit available. It includes all the

parts necessary to replace all the seals in the brake These

parts are indicated in Figure 9-28 with a symbol.

NOTE: The needle valve must be in the open position for

the brake system to operate properly. If it is not

open, the charging pump will cycle every time the

brake pedal is depressed and if the crane’s engine

stops there may not be enough pressure to stop

the crane.

NOTE: When removing seals and backup rings be careful

not to scratch or mar the pistons.

NOTE: The linings must be kept free of grease, oil, etc.

1. Close the needle valve located under the accumulator

Figure 9-11. This will shut off hydraulic pressure to the

parking brake. Release system pressure by actuating

the service brake pedal until no resistance is felt. Then,

engage and disengage the parking brake to release its

pressure.

2. Slowly, loosen the hydraulic hose from the parking

brake. Some pressure may still be present in the

hydraulic hose. Let the pressure escape and then

remove the hydraulic hose.

3. Cap the hydraulic hose to prevent contamination from

entering the hydraulic system.

4. Loosen lock nut 8 Figure 9-28 and back off adjusting bolt

7.

WARNING

Before replacing the parking brake seals, make sure that

the machine is on level ground. Place chocks on both

sides of the four tires. Remove the ignition key. If these

precautions are not adhered to, the crane could run you

over while performing the repair.

Reference Only

Loading...

Loading...