11-61

5540F/YB5515 SERVICE MANUAL STRUCTURALS

Assembly

1. If removed, install bushing 2 and 4 into worm housing 1

and worm housing cover 3.

2. Install bearing cups 8 and bearing cones 9 onto worm

shaft 7.

3. Install the assembled worm shaft and bearings into

worm housing 1. Seat the bearing cones into the worm

housing.

4. Install a new oil seal 16 into worn housing 1.

5. Insert output pinion shaft 7 through oil seal 16and

bushing 2.

6. Install the lower retainer ring 12 over the output pinion

shaft.

7. Install worm gear 5 onto output gear shaft 7. Mesh the

teeth of the worm gear with the teeth of the worm.

8. Install retaining ring 14. Install the top retaining ring 12.

9. Place a new 0.031” thick gasket 19 on bearing retainer

10.

10. Attach the gasket and bearing retainer to the worm

housing using four lockwashers 27 and capscrews 23.

11. Place a new 0.015” thick gasket 17 and shim 22 on the

motor adapter 11.

12. Using four socket head capscrews 21 and lockwashers

25 attach motor adapter to 11 to worm housing 1.

13. Check the backlash between the worm and worm gear

in both directions. Backlash should be 0.010” (0.254

mm) or less.

14. Place a new worm cover gasket 20 on the face of worm

housing 1. Using six capscrews24 and lockwashers 26,

attach worm housing cover 3 to the worm housing. Coat

the threads of capscrews 23 with Loctite No. 242 before

installation.

15. Check the end play on the worm shaft using a dial

indicator. Set the base of dial indicator on the worm gear

housing. Turn the output gear in one direction slightly.

Place the dial indicator on the end of the worm shaft and

set it to zero (0). Turn the output gear in the opposite

direction and read the dial indicator. The end play must

be between 0.000 to 0.002 inches (0.000 to 0.05 mm).

Add or remove shims as necessary to obtain the correct

end play.

16. Fill the gear housing with the recommended gear

lubricant. See Section 3.

17. Using a new gasket, install the hydraulic motor 13 to

motor adapter 11 using capscrews 28 and lockwashers

25.

Installation

1. Install the gearbox in reverse order of removal.

2. Align the pinion gear with the swing gear following the

instructions.

OUTRIGGERS

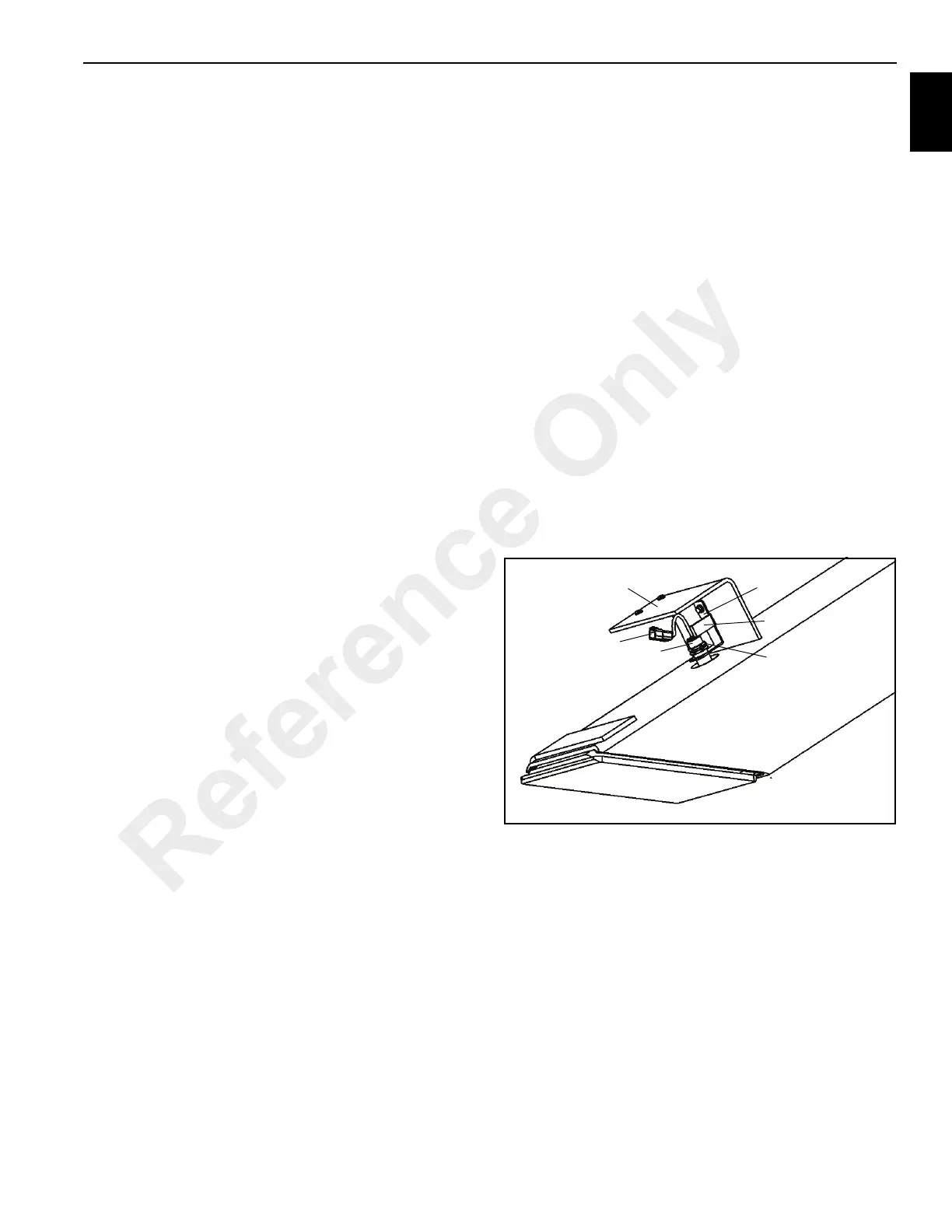

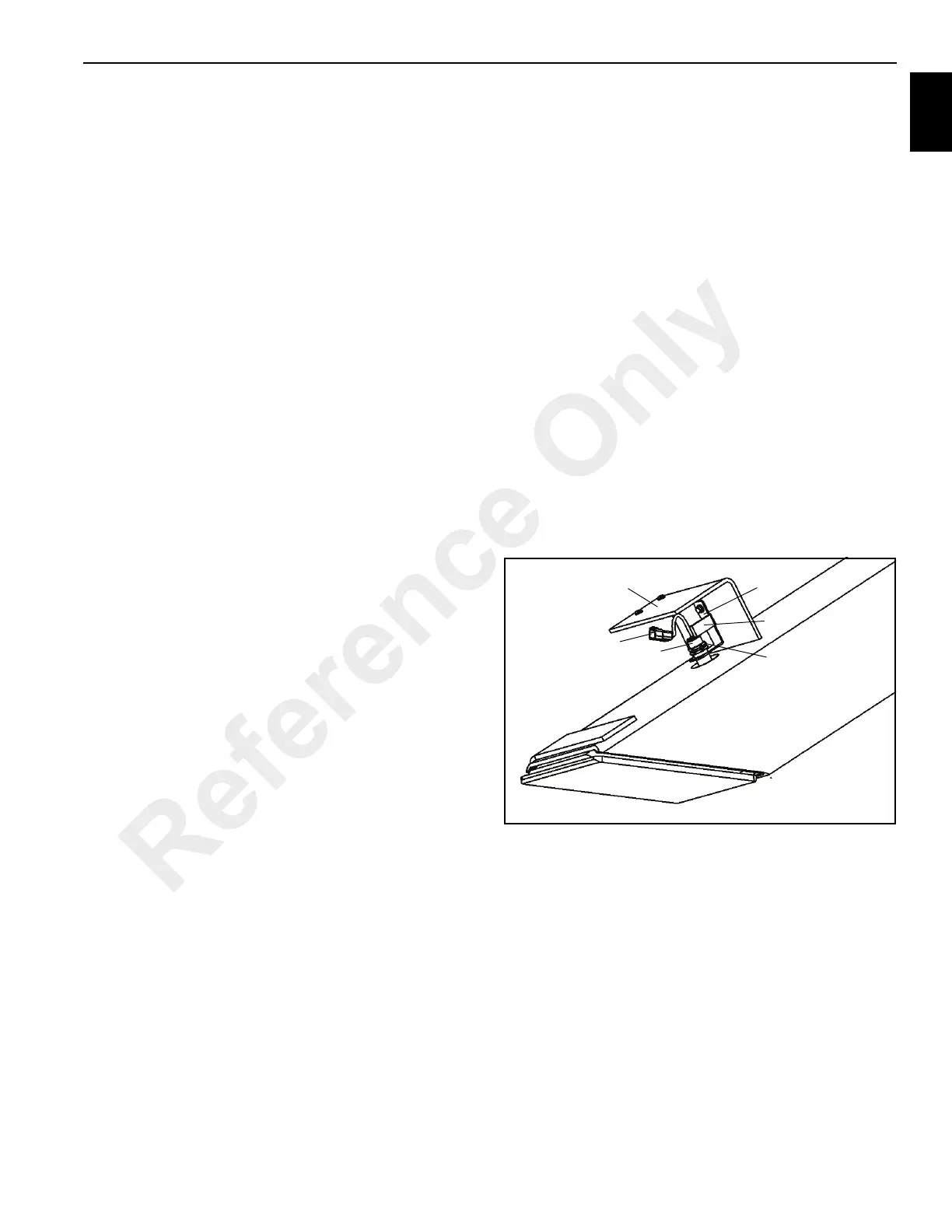

Outrigger Monitoring System

(OMS)(Optional—Standard in North

America)

The Outrigger Monitoring System (OMS) proximity switches

(if equipped) are mounted outside the outrigger housing

tubes. The proximity switches identify whether an outrigger

beam is at the fully extended position or at any position less

than fully extended.

Removal

1. Disconnect switch cable (1) from harness.

2. Remove switch mounting bracket (2).

3. Remove jam nuts (3) and thread switch (4) out of the

mounting bracket.

Installation

1. Feed cable through the mounting bracket and jam nuts.

2. Thread switch through mounting bracket.

3. Thread nuts on switch.

4. Thread switch up until it touches tab (5) of mounting

bracket and LED is pointed away from the bracket.

5. Tighten jam nuts against mounting bracket.

6. Install bracket with switch onto outrigger angle bracket

(6).

7. Adjust bracket and/or switch to have .12 to .38 in (3 to 10

mm) gap beween end of switch and outrigger beam.

8. Connect switch cable to wire harness.

Reference Only

Loading...

Loading...