GROVE Published 10-21-2010, Control# 198-04 1-11

5540F/YB5515 SERVICE MANUAL

Torque wrenches are precision instruments and must be

handled with care. To ensure accuracy, calibrations must be

made on a scheduled basis. Whenever there is a possibility

that a torque wrench may have been either overstressed or

damaged, it should immediately be removed from service

until recalibrated. When using a torque wrench, any erratic or

jerking motion can result in the application of excessive or

improper torque. ALWAYS use a slow, even movement and

STOP when the predetermined value has been reached.

When using step wrenches, calculated wrench settings are

valid only when the following conditions are met:

• Torque wrenches must be those specified and forces

must be applied at the handle grip. The use of handle

extensions will change applied torque to the bolt.

• All handles must be parallel to the step wrench during

final tightening. Multiplier reaction bars may be

misaligned no more than 30 degrees without causing

serious error in torque.

• Multiplier bar handles must be propped or supported

within the outer 1/4 of the handle length, or serious

under or over tightening will occur.

To convert pounds-foot (lb-ft) of torque to newton meters

(Nm), multiply the pounds-foot quantity by 1.3558.

To convert pounds-inch (lb-in) of torque to newton meters

(Nm), multiply the pounds-inch quantity by 0.11298.

Torque Values

The following tables list the torque values for both ASME

standard and metric fasteners. The tables list the values for

grade 5 and grade 8 zinc-flake coated, untreated (black)

finish and stainless steel fasteners.

Table 1-2: UNC (Course) Thread: Torque Values for Zinc-Flake Coated and Untreated Fasteners

NOTE: Studs shall be torqued using capscrew values when grade is known.

Bolt Diameter - Inches

Torque Values (Pounds-Foot, Maximum/Minimum)

SAE Grade 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4 1-1/2

Zinc-Flake

5 7 14 25 40 61 88 121 213 342 512 636 884 1532

8 10 20 36 57 86 124 171 301 483 723 1032 1433 2488

Untreated

5

9.0

7.7

19

17

32

30

52

48

78

72

114

106

156

144

270

249

416

384

606

560

813

751

1141

1053

2028

1865

8

12.5

11.5

26

24

48

44

73

67

120

110

161

143

234

216

385

355

615

567

929

857

1342

1234

2043

1885

3276

3024

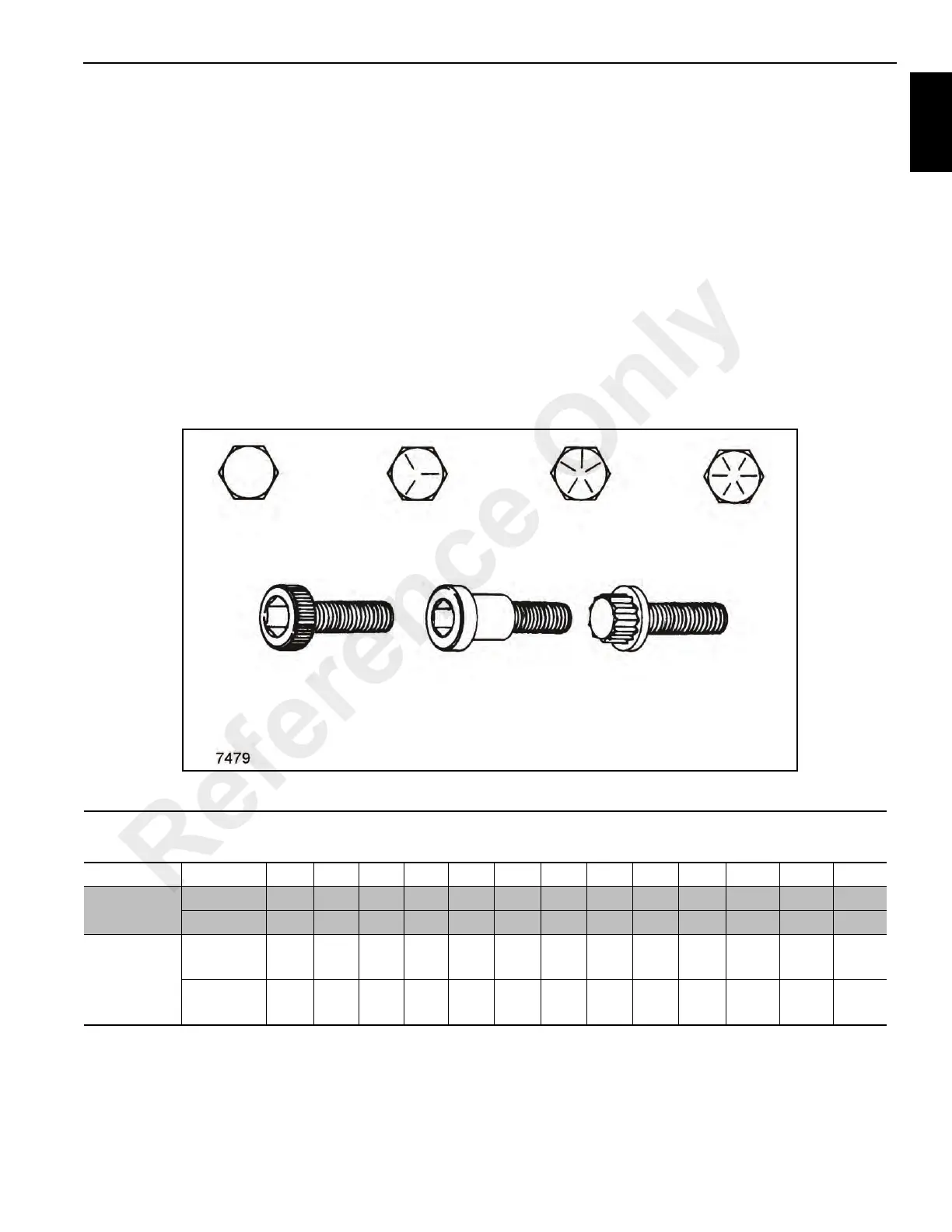

SAE Grade 1

and Grade 2

HHCS

SAE Grade 5

HHCS

SAE Grade 7

HHCS

SAE Grade 8

HHCS

Serrated

Flange Head

Socket Head

Shoulder

Screw

Socket Head

Capscrew

FIGURE 1-10

Reference Only

Loading...

Loading...