HYDRAULIC SYSTEM 5540F/YB5515 SERVICE MANUAL

4-8 Published 10-21-2010, Control# 198-04

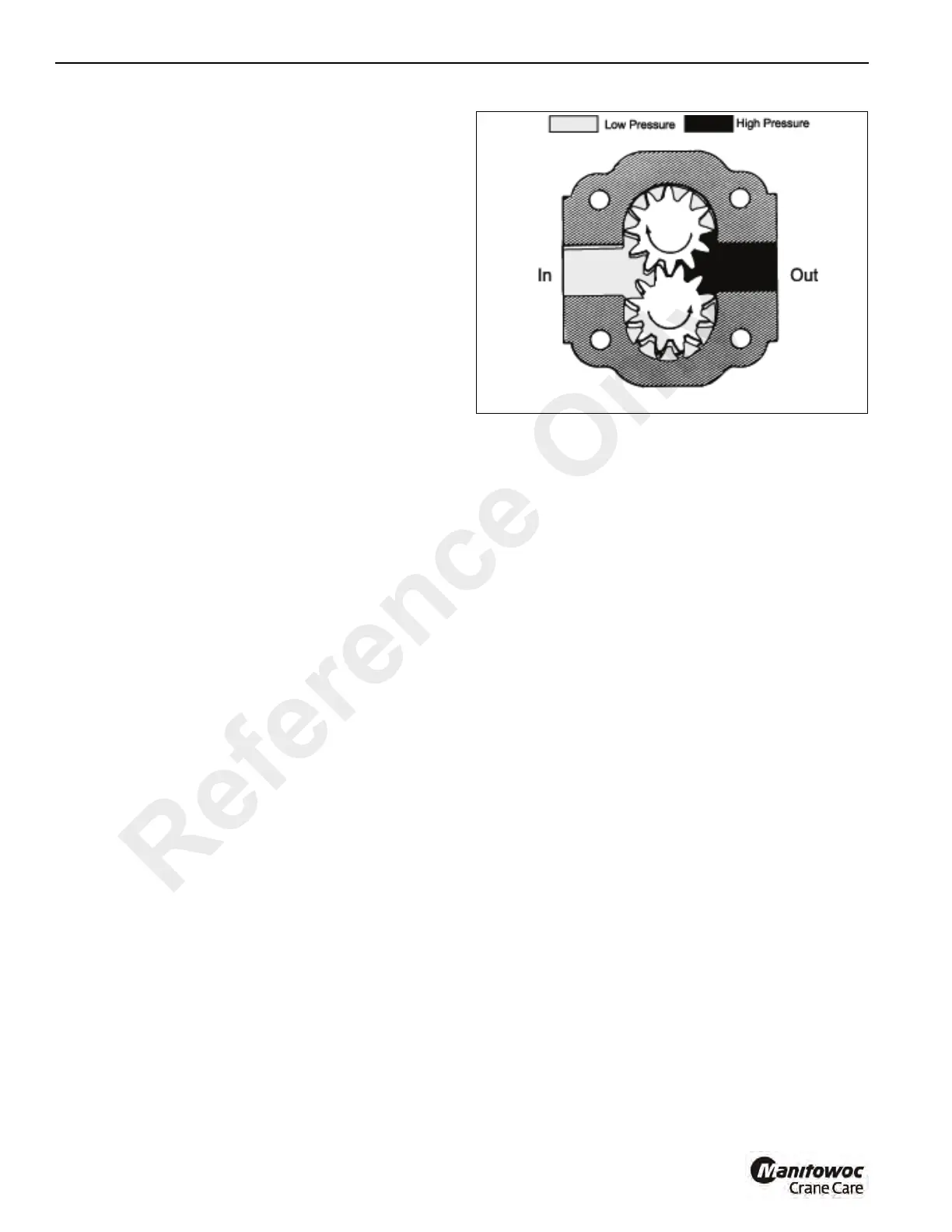

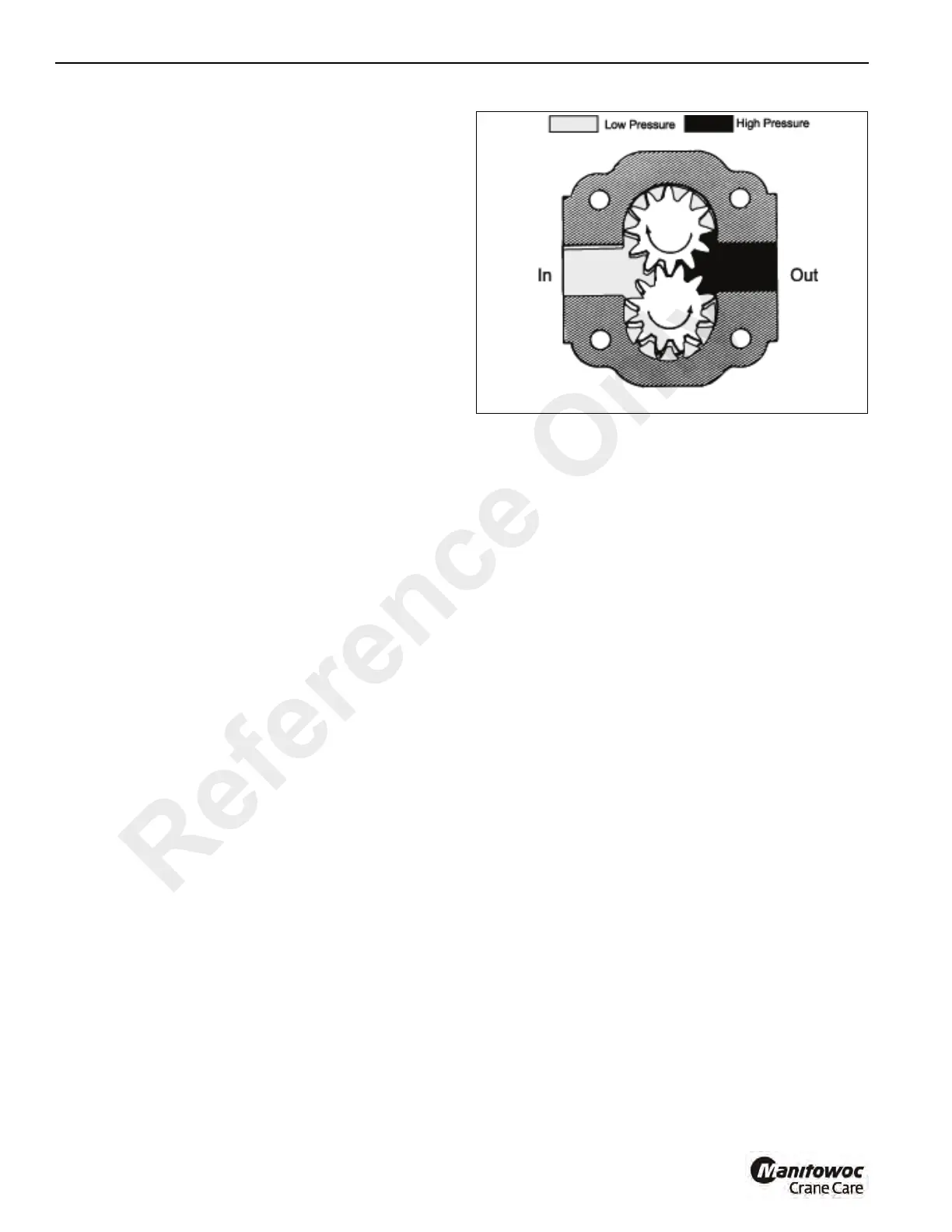

Lubrication of internal components is provided through

passages in the hydraulic pump body and grooves in the

pressure plates. A lip seal on the shaft and o-rings between

the sections prevent external leakage in the pump.

Reference Only

Loading...

Loading...