© Martin Engineering GmbH 39 M3727UK-09/15

Maintenance

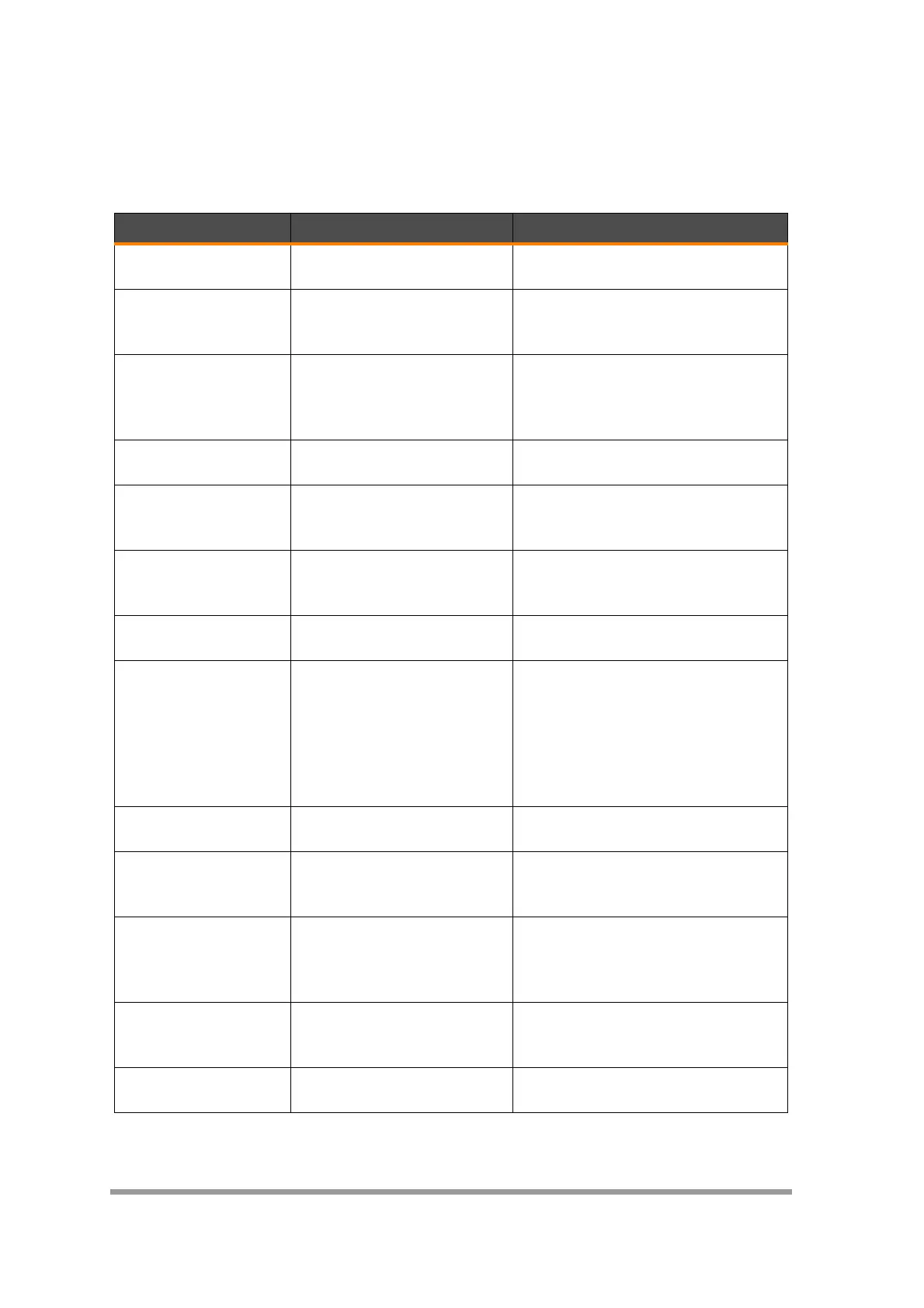

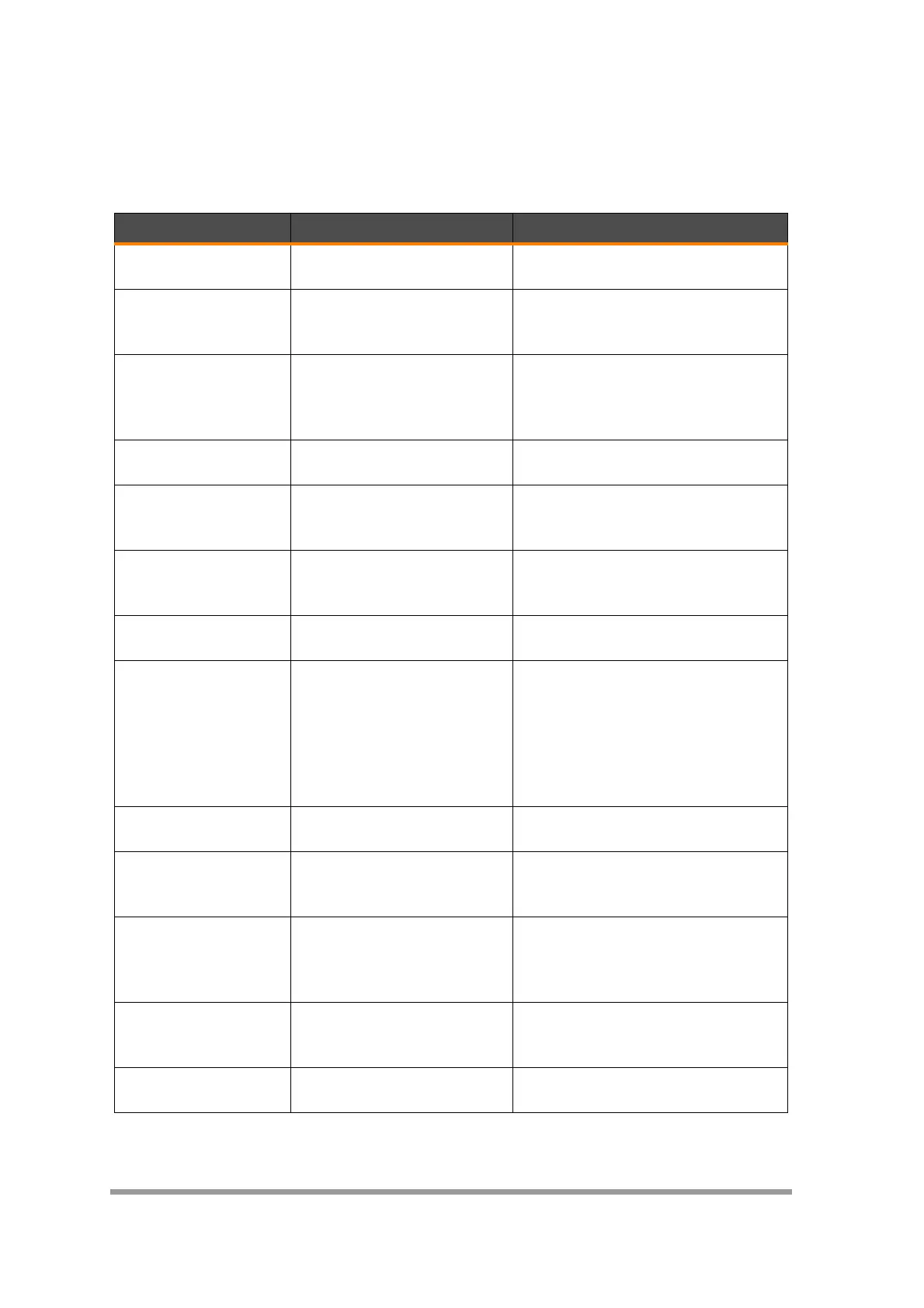

6.3 Inspection and maintenance

6.3.1 Routine inspections

Interval Part to be serviced Action

monthly Check the air-carrying parts

for leaks.

Seal any leaky points or replace

the affected part.

monthly Check the attachment and

layout of all of the air-

carrying parts.

Replace any sharply bent lines

(note the bending radius), repair

loose connections.

monthly Check the functional

capacity of all valves,

locking mechanisms and

the maintenance unit.

Replace defective parts

immediately.

monthly Check the safety valve. Note the safety valve's

documentation.

monthly Check the function of the

gauge (if provided).

Clean the glass and check the

scale for legibility, replace the

gauge if needed.

monthly Check the safety cable. The cable clips must be tight and

the components must not be

damaged or corroded.

monthly Check all of the warning

labels.

Clean the warning labels or replace

illegible labels immediately.

yearly /

50,000 firings

Drain the condensate from

the air cannon tank.

Close the compressed air lines.

Fire the air cannon when its tank is

depressurised. Open the safety

valve.

Open the drain screw and collect

the condensate in suitable

containers.

yearly /

50,000 firings

Check the air cannon for

corrosion.

Repair the corroded areas, replace

if needed.

yearly /

50,000 firings

Check the screw

connections and bolts.

Retighten the screw connections.

Correct the bolt position and

replace if needed.

yearly /

50,000 firings

Check the welding seam. Take the air cannon out of service

immediately when damaged

welding seams are detected and

replace the tank immediately.

yearly /

50,000 firings

Check the air cannon's

valve, piston and nozzle for

damage.

Replace defective parts or have

them repaired by Martin

Engineering.

yearly /

50,000 firings

Check electrical cables and

interfaces.

Replace defective cables and

interfaces.

Tab. 4: Inspection table

Loading...

Loading...