SERVICE MACHINE SAFETLY

32

cod. G19503950

3

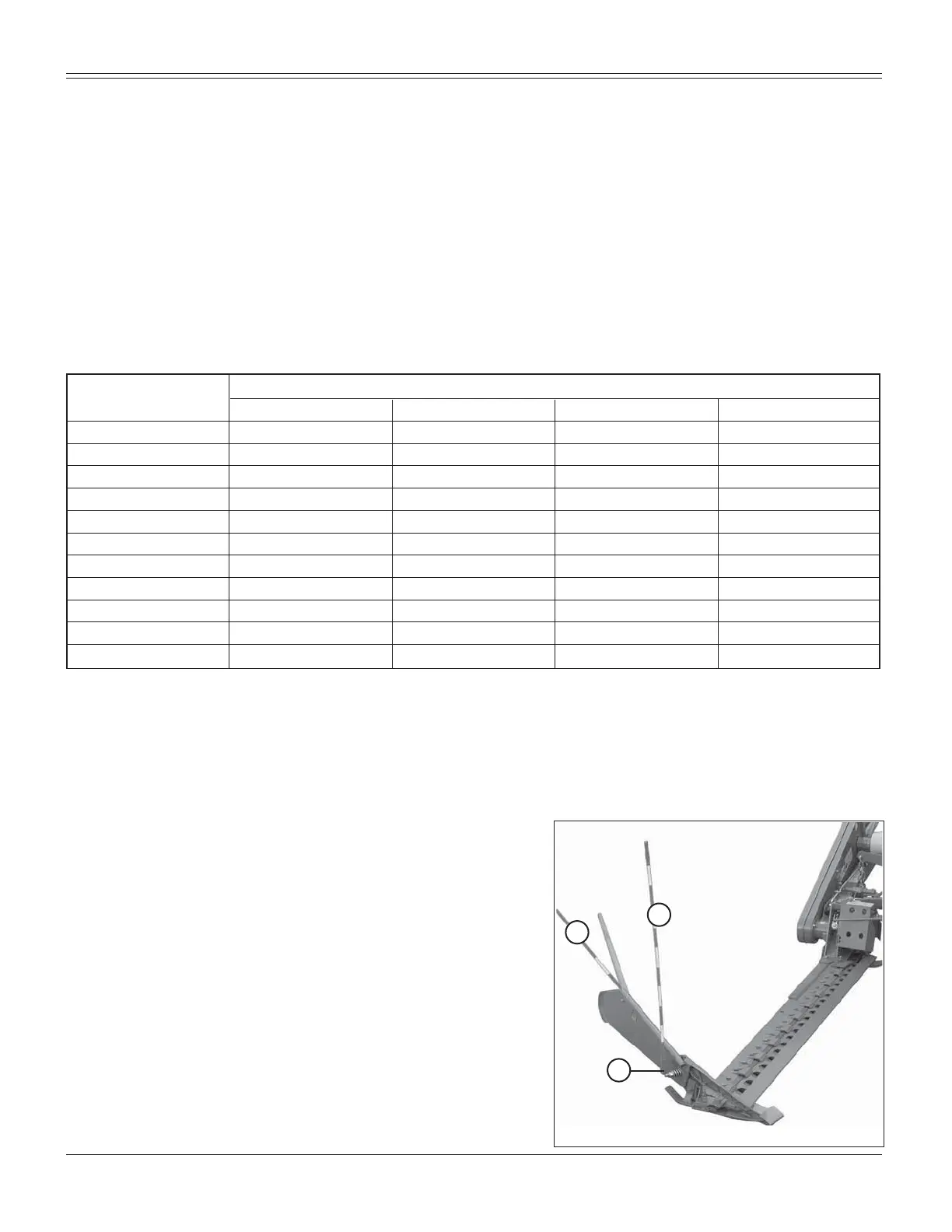

Fine pitch screws CLASS

6.6 8.8 10.9 12.9

M8 x 1 15 (11) 26 (19) 36 (26.5) 44 (32.5)

M10 x 1.25 30 (22) 52 (38) 74 (54) 88 (65)

M12 x 1.25 51 (37.5) 91 (67) 127 (94) 153 (113)

M14 x 1.5 81 (60) 143 (105) 201 (148) 241 (178)

M16 x 1.5 120 (88) 214 (158) 301 (222) 361 (266)

M18 x 1.5 173 (127) 308 (227) 433 (319) 520 (384)

M20 x 1.5 242 (178) 431 (318) 606 (447) 727 (536)

M22 x 1.5 321 (237) 571 (421) 803 (592) 964 (711)

M24 x 2 411 (303) 731 (539) 1028 (758) 1234 (910)

M27 x 2 601 (443) 1070 (790) 1504 (1110) 1806 (1333)

M30 x 2 832 (614) 1480 (1090) 2081 (1535) 2498 (1843)

(metric)

(Table 1)

'RQRWSURFHHGZLWKPDLQWHQDQFHDQGFOHDQLQJLIWKHSRZHUWDNHRIIKDVQRWEHHQGLVFRQQHFWHG

¿UVWWKHHQJLQHSRZHURIIWKHKDQGEUDNHSXOOHGDQGWKHWUDFWRUEORFNHGZLWKDZRRGHQEORFNRU

stone of the right size under the wheels.

3HULRGLFDOO\FKHFNWKDWWKHEROWVDQGQXWVDUHWLJKWDQGLIQHFHVVDU\WLJKWHQWKHPDJDLQ)RUWKLVLW

would be advisable to use a torque wrench, respecting the values of 52 Nm for M10 bolts, resistance

class 8.8, and 143 Nm for M14 bolts resistance class 8.8 (Table 1: Bolts tightening torques).

'XULQJDVVHPEOLQJPDLQWHQDQFH FOHDQLQJ¿WWLQJ HWF ZLWKWKH PRZLQJPDFKLQH UDLVHGSODFH

adequate supports under the equipment as a precaution.

7KHVSDUHSDUWVPXVWFRUUHVSRQGWRWKHPDQXIDFWXUHU¶VVSHFL¿FDWLRQVUse only original spares.

Bolts tightening torques - settings given in Nm (lb-ft)

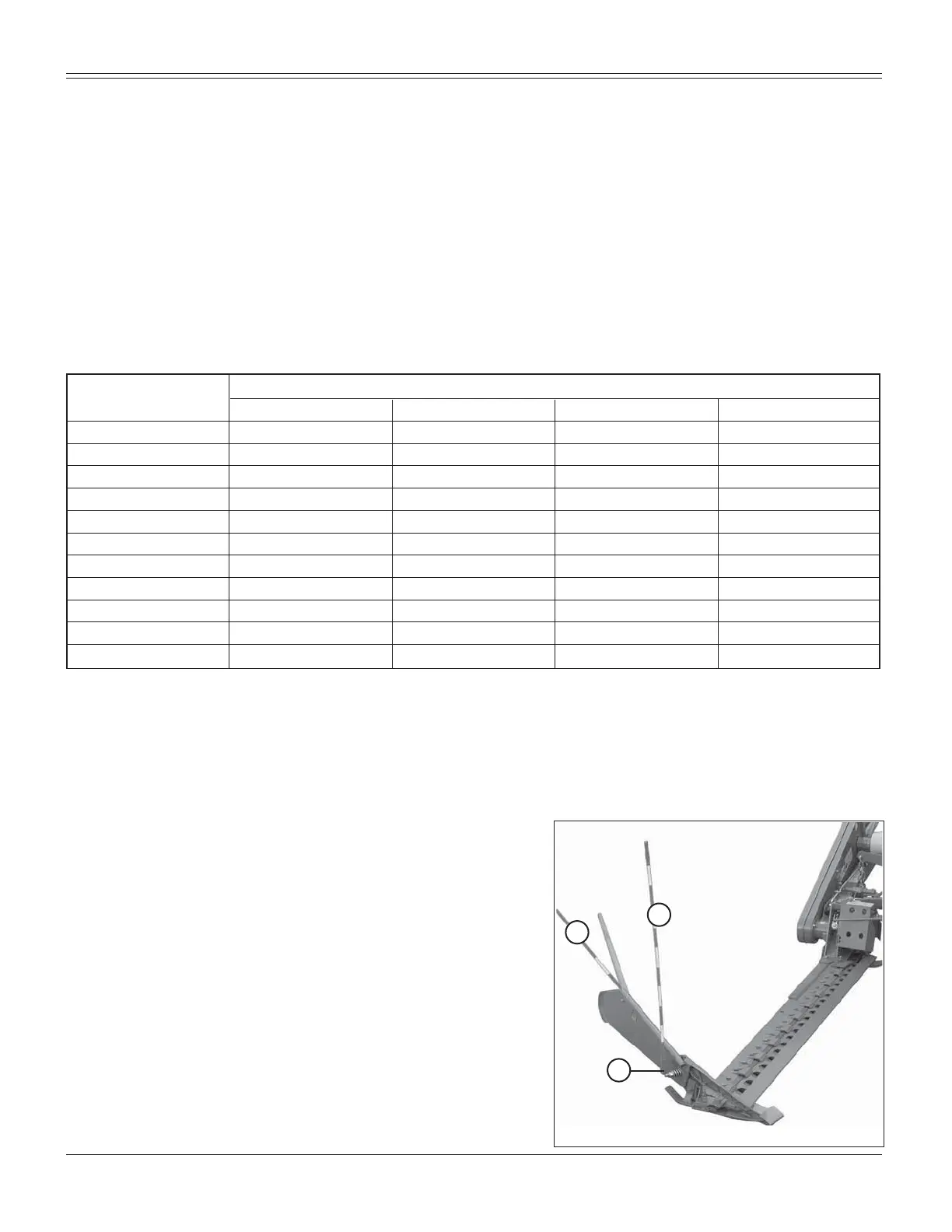

Hazard bar

The hazard bar has been included with the equipment

of the machine for safety reasons, to indicate the space

occupied by the mower at work. For working, position the

hazard bar in position (A1, Fig. 56) and lock it in place with

the screw (B). For transport put it in position (A2).

Fig. 56

B

A2

A1

Loading...

Loading...