SERVICE

36

cod. G19503950

3

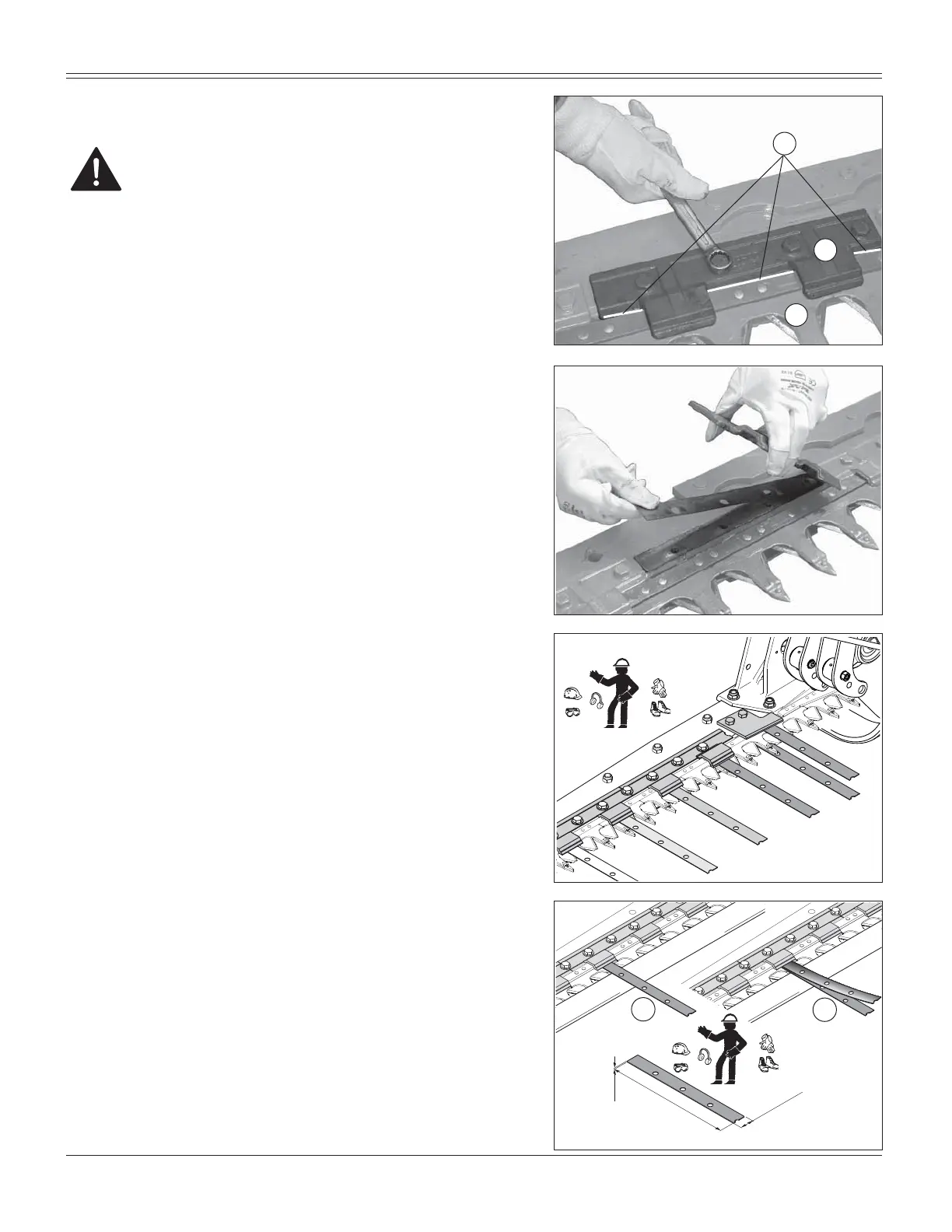

Checking the clearance tolerance

Fig. 63

Fig. 64

302 mm

30 mm

1 mm

1.18 inches

11.9 inches

thicknes

~0.04 inches

Fig. 65

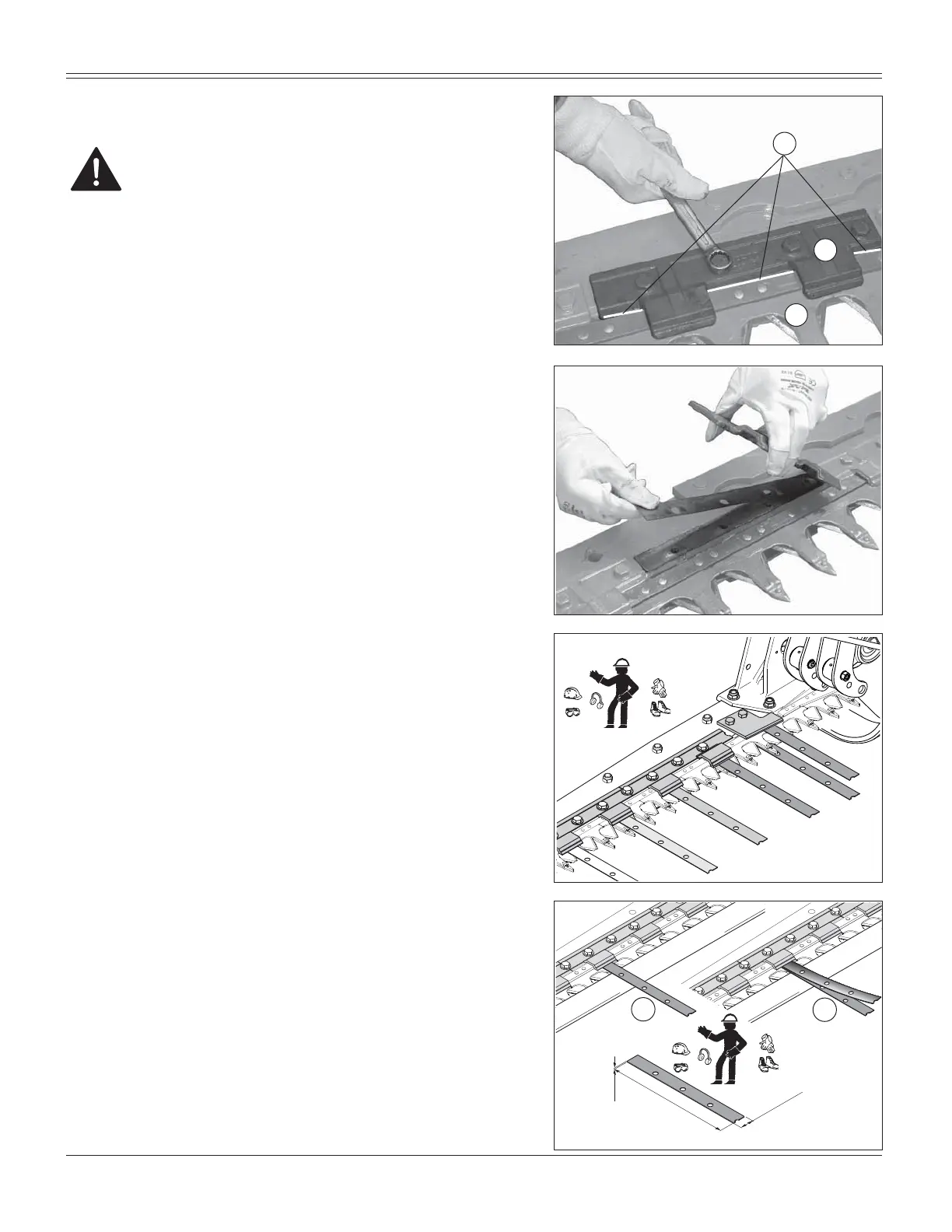

Fig. 66

Z2

Z1

ATTENTION

It is absolutely essential to disengage the trac-

tor pto, lower the mowing machine, switch off

the tractor, ensure that this is at a complete

standstill and remove the key before servicing,

adjusting the implement for work. All assembly

operations must be carried out on a work bench.

Before activating the mower, one must periodically check

that the blade holder rod (M, Fig. 63) and the upper blade

guides (N) are coupled properly.

After many hours of work, wear of the blade guide material

may be seen, and this will cause an increase in the coupling

tolerance with the tooth blade.

An excessive coupling tolerance between the parts results

in material entering between the same, causing likely

breakage of the cutting blades or parts of them, also com-

promising the quality of the cut.

In contrast, a reduced coupling tolerance generates a

strong sliding friction of the blade with consequent bre-

akage of the blade holder rod, the blade head or other

elements of the hinge (connecting-rod assembly).

It is therefore advisable to restore the correct tole-

rance!

The check must be carried out on all blade guides (Fig. 65)

using a ~0.04 inches (1 mm) thick shim plate, supplied.

$OZD\VXVHSHUVRQDOSURWHFWLYHHTXLSPHQW

The tolerance allowed for optimal coupling is deter-

mined by the insertion of a single plate (Z1, Fig. 66).

,IDSODWHGRHVQRW¿WEHWZHHQWKHWHHWKEODGHDQGWKHEODGH

guide one must add a shim (Fig. 63-64);

If instead two coupled plates can be inserted (Z2, Fig. 66)

one must remove a shim to restore the optimal coupling

tolerance conditions.

CAUTION

:KHQ¿WWLQJWKHEODGHJXLGHLWLVLPSRUWDQWWROHDYHD

coupling tolerance of about ~0.04 inches (1 mm) with

the sections holder rod (L, Fig. 63).

L

M

N

Loading...

Loading...