SERVICE

33

cod. G19503950

3

/XEUL¿FDWLRQ

:$51,1* )LUPO\EORFNVLFNOHEDURQKRUL]RQWDOVXUIDFH

$OZD\VNHHSRLOVDQGJUHDVHVZHOODZD\IURPFKLOGUHQ¶VUHDFK

$OZD\VWKRURXJKO\UHDGWKHZDUQLQJVDQGSUHFDXWLRQVLQGLFDWHGRQWKH

containers. Avoid contact with the skin.

$OZD\VWKRURXJKO\DQGIXOO\ZDVKDIWHUXVH7KHXWLOL]HGRLOVVKRXOGEH

treated in compliance with the current anti-pollution laws.

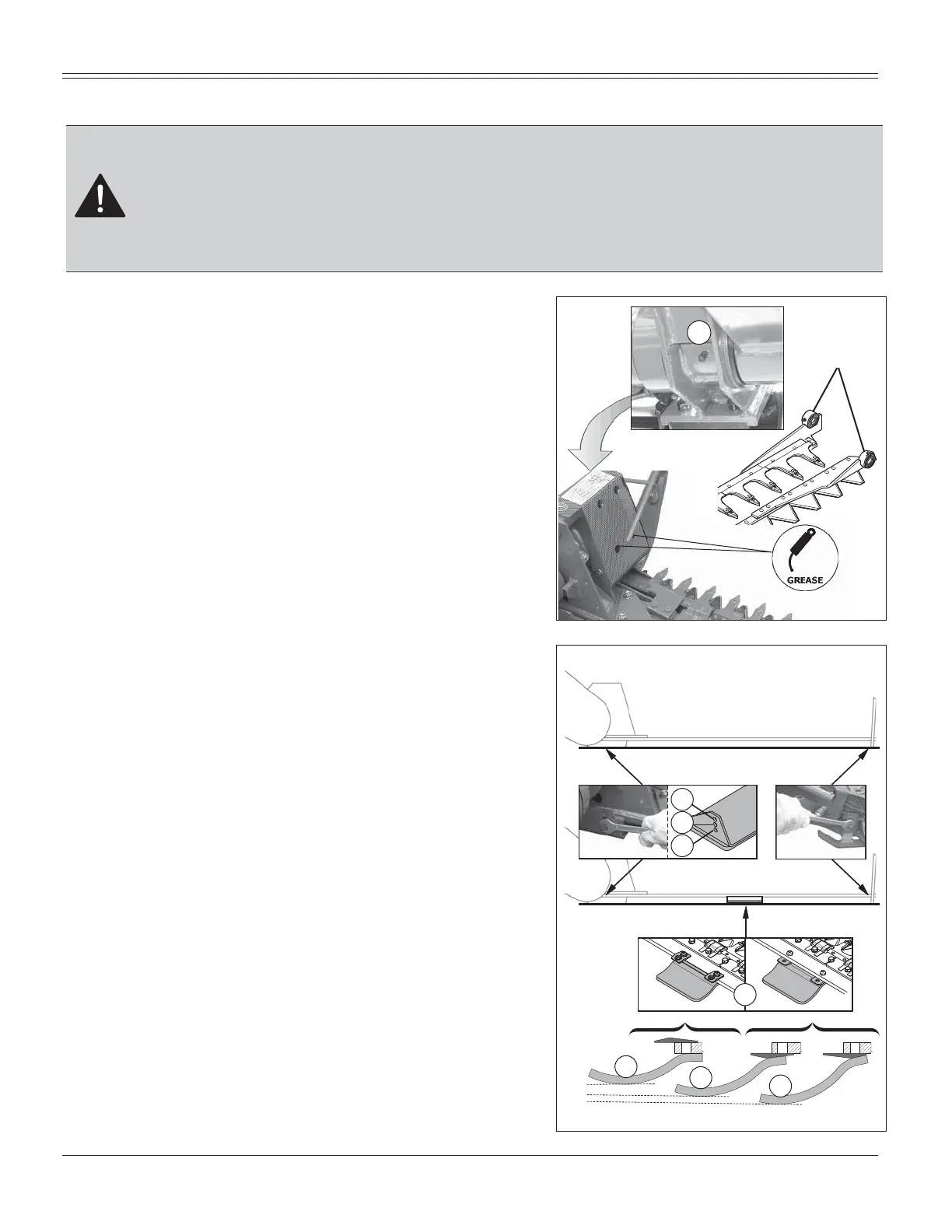

Routine maintenance

'XULQJWKH¿UVWZRUNLQJKRXUVFKHFNWKDWWKHVFUHZV

are tight (Fig. 60).

Every 2 work hours

*UHDVHSRLQW$DQG&)LJ

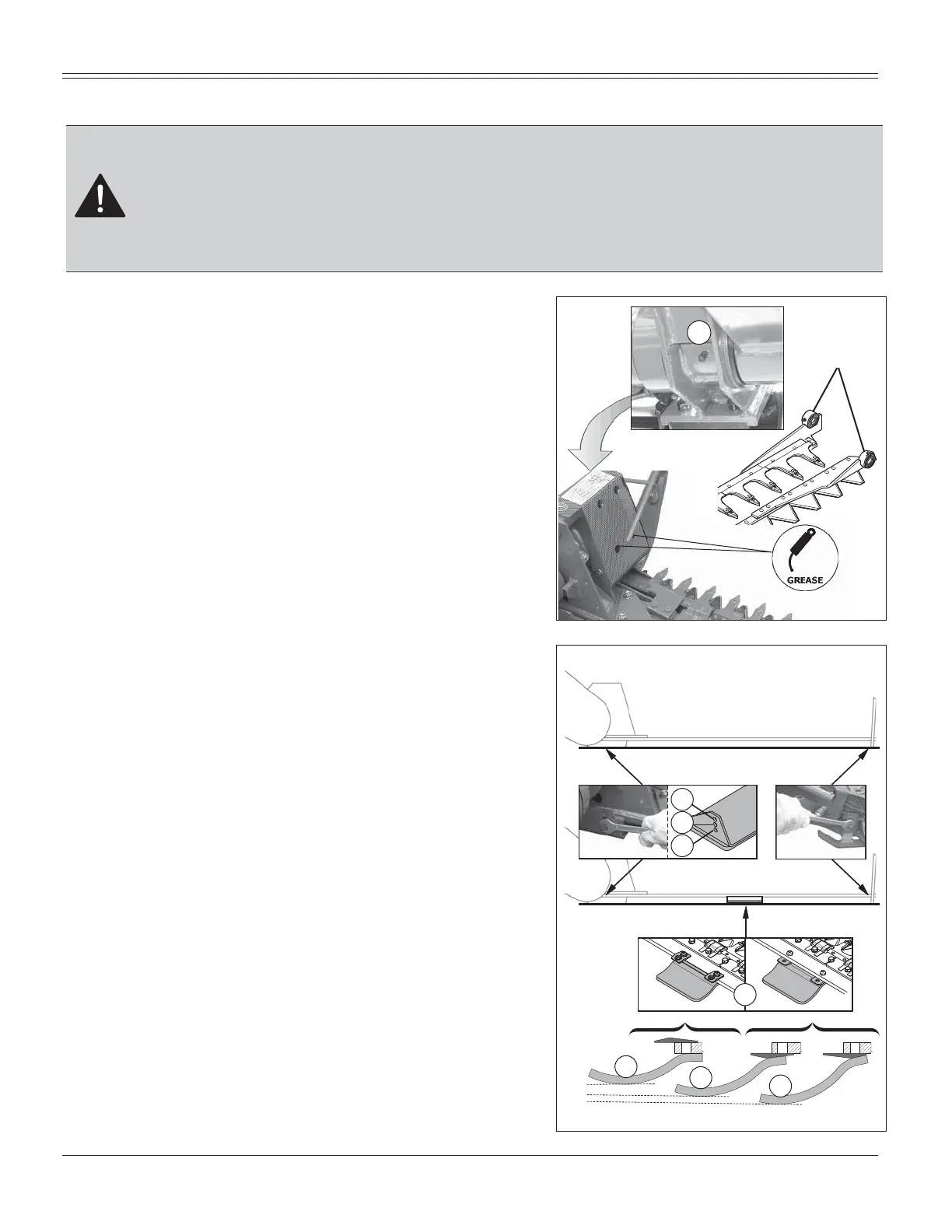

Wear-proof skids (optional)

In the presence of abrasive terrain (rocky, sandy, etc.)

wear-proof skids can be provided on request to protect

the cutterbar.

External wear-proof skids are available in all versions (D-

E, Fig 58), whereas, the central wear-proof skid is also

applied only in the versions with a cutting width of L. 2.05

and L. 2.35 (F, Fig 58).

They can be adjusted in 3 different positions to obtain 3

different cutting heights.

It is important to set all the wear-proof skids to the same

position, which corresponds to the same cutting height.

When adjusting the central wear-proof skid, pay utmost

DWWHQWLRQWRWKHSUHFLVHPRXQWLQJRIWKHDGMXVWPHQWGHÀHF-

tor to obtain the correct cutting height.

Every 8 work hours

*UHDVHWKHFDUGDQVKDIWDQGLWVWHOHVFRSLQJSDUWV

$GMXVWEHOWWHQVLRQSHULRGLFDOO\E\DGMXVWLQJQXW*)LJ

59). Check tension via the viewing panel on the belt

guard. Belt slack must not exceed 1 inch. It is essential

to close the inspection hatch with the relative lid after

the belts have been examined.

Every 50 work hours

&KHFNWKHWLJKWQHVVRIWKHFRQQHFWLQJURGEROWVUHJX-

larly (Fig. 60).

&KHFNLQJWKHFOHDUDQFHWROHUDQFH

A

Fig. 57

B

C

L. 1.45/1.75

L. 2.05/2.35

E

D

3

2

1

1

2

3

F

Fig. 58

Loading...

Loading...