32

Calder Brothers Corp

V 1.0

Model: 1860 Paver

SN:

Serial Number Range:

874-S-86TCX5Y2*03874 to _____________

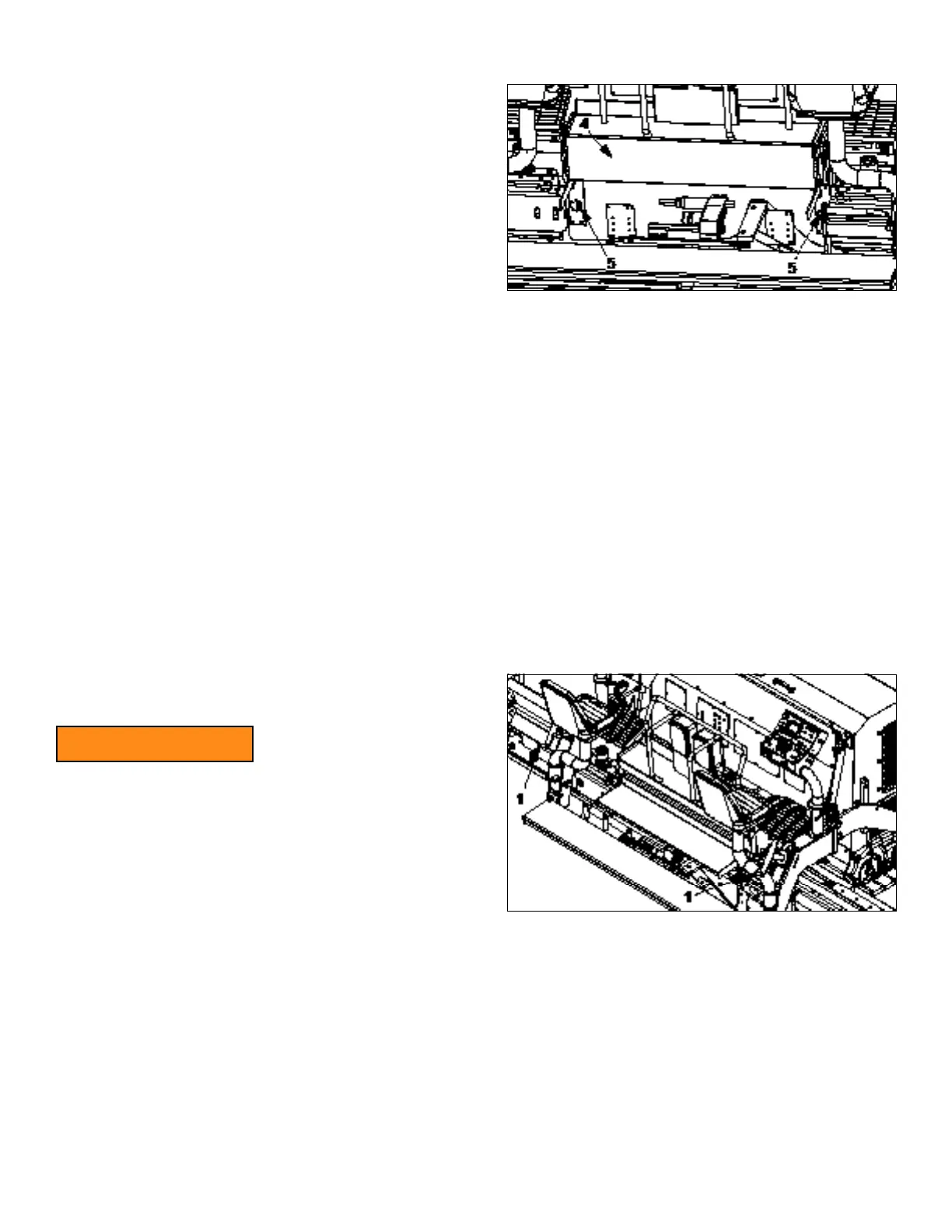

10. Raise center walk board (4) exposing the cam style

adjustment (5) for each side. Loosen jam nut on locator

bolt and fully remove the locator bolt. Rotate the cam

bolt clockwise to raise pre-strike off. Install locator bolt

and tighten jam nut.

From this initial factory screed setting you will need to

make a match height adjustment in the down direction

when you start paving.

5.4 Setting Screed To Pave

The procedure in sections 5.1, 5.2 and 5.3 was set before leaving the factory. It is recommended that before

initial start up, follow procedure in these sections to verify settings.

5.4.1 Before Paving

Screed must be elevated a distance equal to the desired mat depth plus enough extra height to allow for

compaction. To achieve this, the most popular methods are starting blocks or an asphalt pad

• Starting Blocks – A 2.5 in. (63.5 mm) thick starting block is a good for a nished mat of 2 in. (51 mm).

• Compacted Asphalt Pad – A starting block equal to the amount of compaction will be required.

• Non-Compacted Asphalt Pad – Lower the screed fully onto pad, no starting block required.

Starting blocks should be at least as long as the front to rear dimension of the screed plate. They should be

placed lengthwise in the direction of travel, directly below screed depth cranks.

5.4.2 Nulling The Screed And Setting Angle Of Attack

This is adjustment of the screed to a perfectly at position

on either starting blocks or an asphalt pad.

^ WARNING

Crush hazard.

Do not place any part of body under screed.

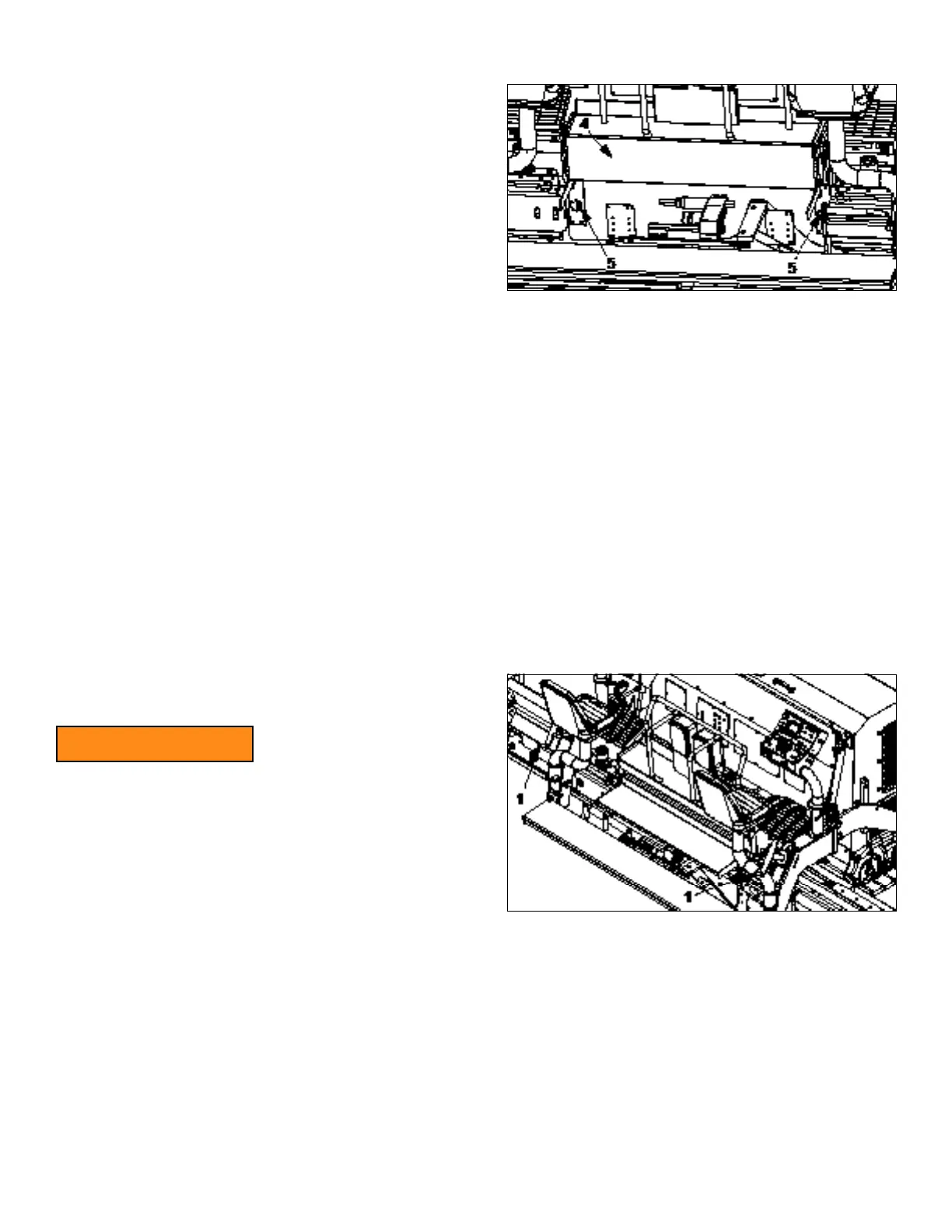

1. Lower screed completely onto starting surface, blocks

or pads.

2. Rotate adjustment crank handles (1) to locate position

of free movement. This is a limited area where adjustment cranks rotate freely in either direction. This is the

nulled position.

3. Rotate adjustment crank handles (1) two full clockwise rotations to set center screed.

4. Start paving and make adjustments as required.

Loading...

Loading...