11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

22

STEP 2 - WELD LIFTGATE TO VEHICLE - Continued

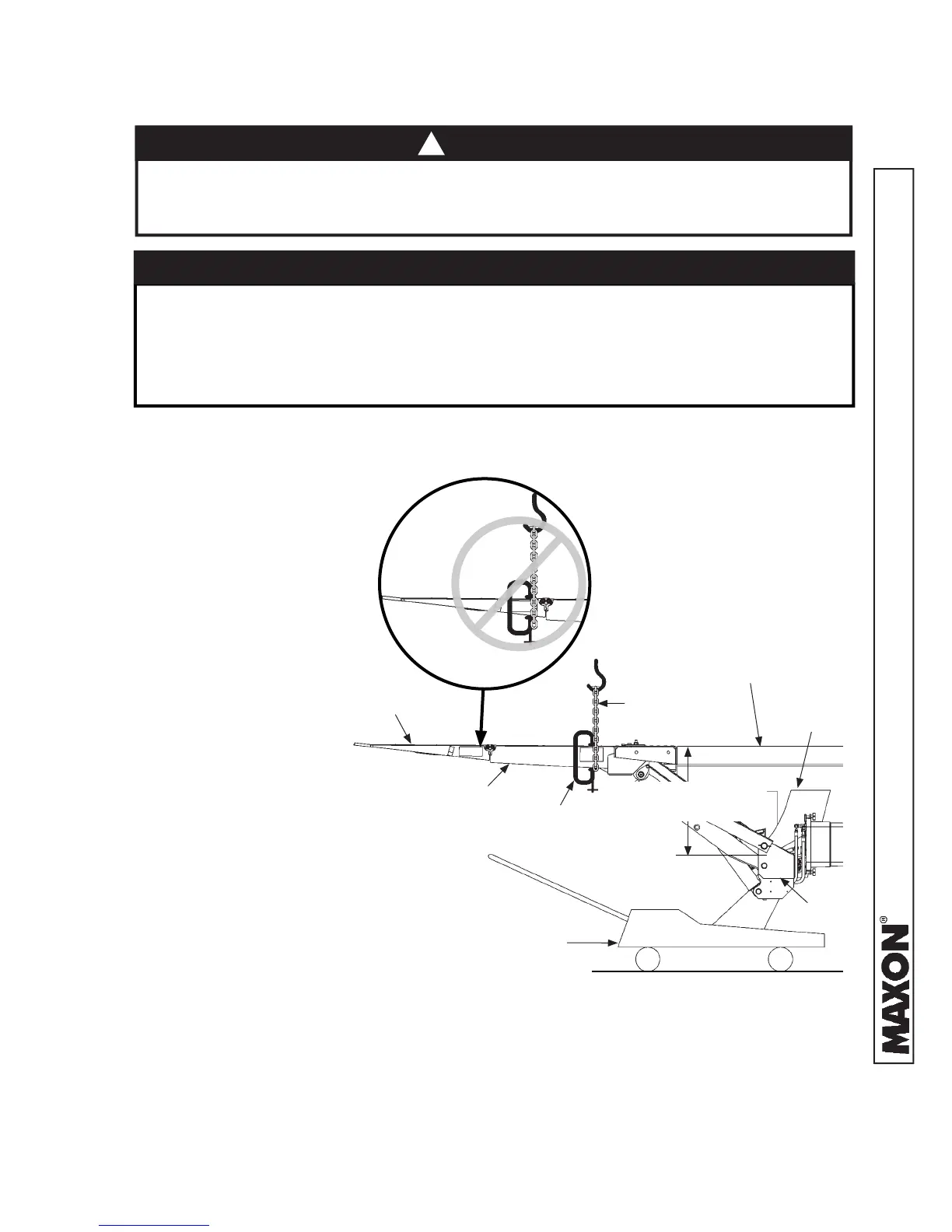

To prevent damage to aluminum fl ipover, NEVER hoist the Liftgate by the

fl ipover. Hoist the Liftgate only by the platform. Refer to the illustrations below

for the “INCORRECT WAY” and the “CORRECT WAY”.

CCORRECT WAY TO HOIST LIFTGATE

FIG. 22-1

CAUTION

FLOOR JACK

(CENTERED ON

MAIN FRAME TUBE)

HOIST CHAIN

MAIN

FRAME

VEHICLE FLOOR

(HORIZONTAL)

MOUNTING

PLATE

FLIPOVER

PLATFORM

!

C-CLAMP

(2 PLACES)

INCORRECT

* TOLERANCE IS +/- 1/4”

* 23-7/8” (GPTWR-25/-3)

* 22-3/8” (GPTWR-4/-5)

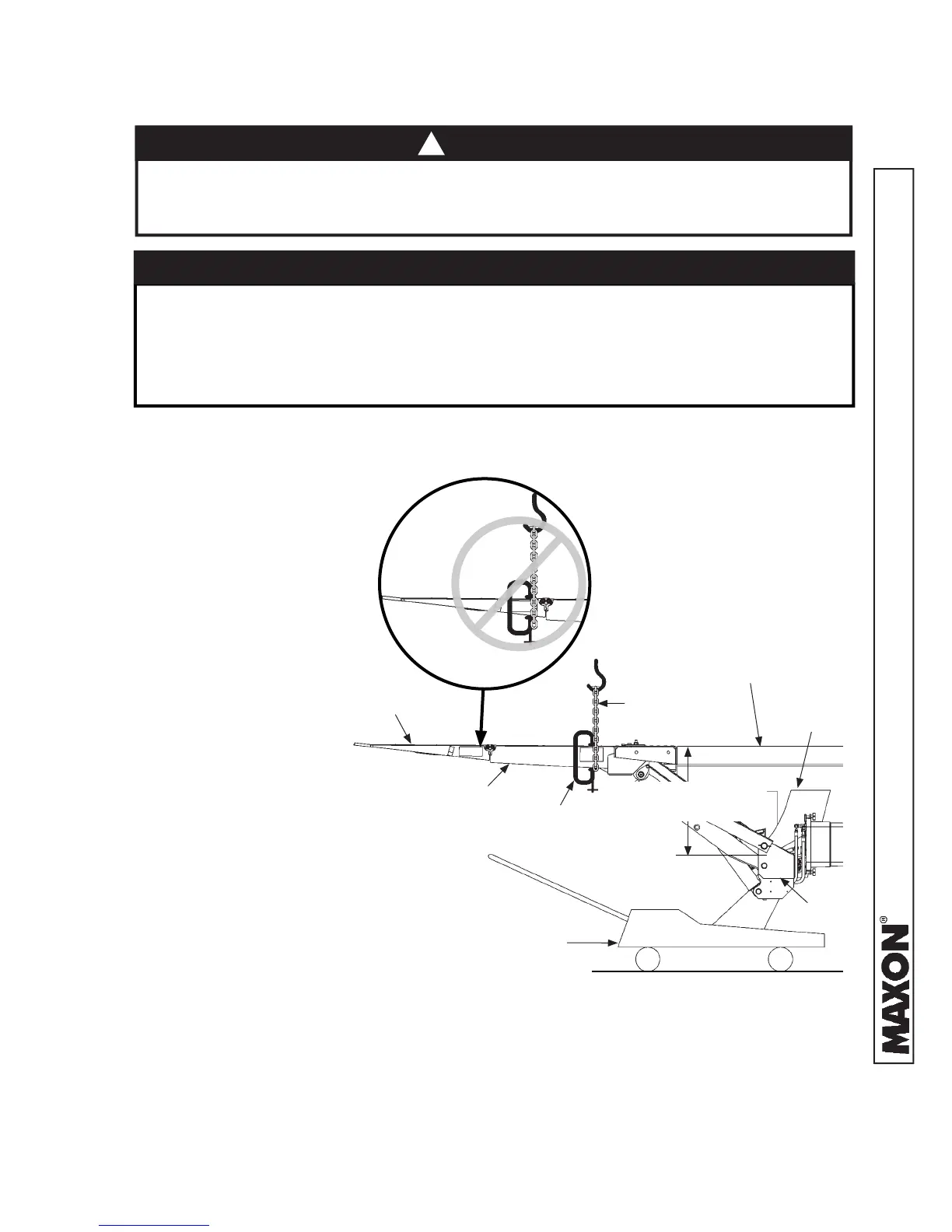

4. Hoist the Liftgate. Then,

place fl oor jack under

center of main frame (FIG.

22-1). Jack the Liftgate into

position. Make sure vehicle

fl oor is horizontal. Maintain

distance between fl oor and

top of main frame as shown

in FIG. 22-1.

Correct fl oor clearance must be maintained when Liftgate is in position and

being welded. Maintain distance between vehicle fl oor and top of main frame

at center of main frame as shown in the instructions. Dimension tolerance is

+/- 1/4”. Never apply force at the ends of the main frame tube to change the

fl oor clearance.

CAUTION

3. Make sure hoist is not

set up the incorrect way

(FIG. 22-1). Place a “C”-

clamp on each side of

platform (FIG. 22-1) to

prevent hoist chain from

slipping off platform.

Wrap chain around plat-

form (FIG. 22-1).

Loading...

Loading...