11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

39

STEP 8 - CHECKING HYDRAULIC FLUID

CAUTION

Keep dirt, water and other contaminants from entering the hydraulic system.

Before opening the hydraulic fl uid reservoir fi ller cap, drain plug and hydrau-

lic lines, clean up contaminants that can get in the openings. Also, protect the

openings from accidental contamination.

+50 to +120 Degrees F - Grade ISO 32

Below + 70 Degrees F - Grade ISO 15 or MIL-H-5606

NOTE: Liftgate is shipped with ISO 32 oil. Use correct oil for climate conditions.

See TABLES 40-1 & 40-2 for recommended brands.

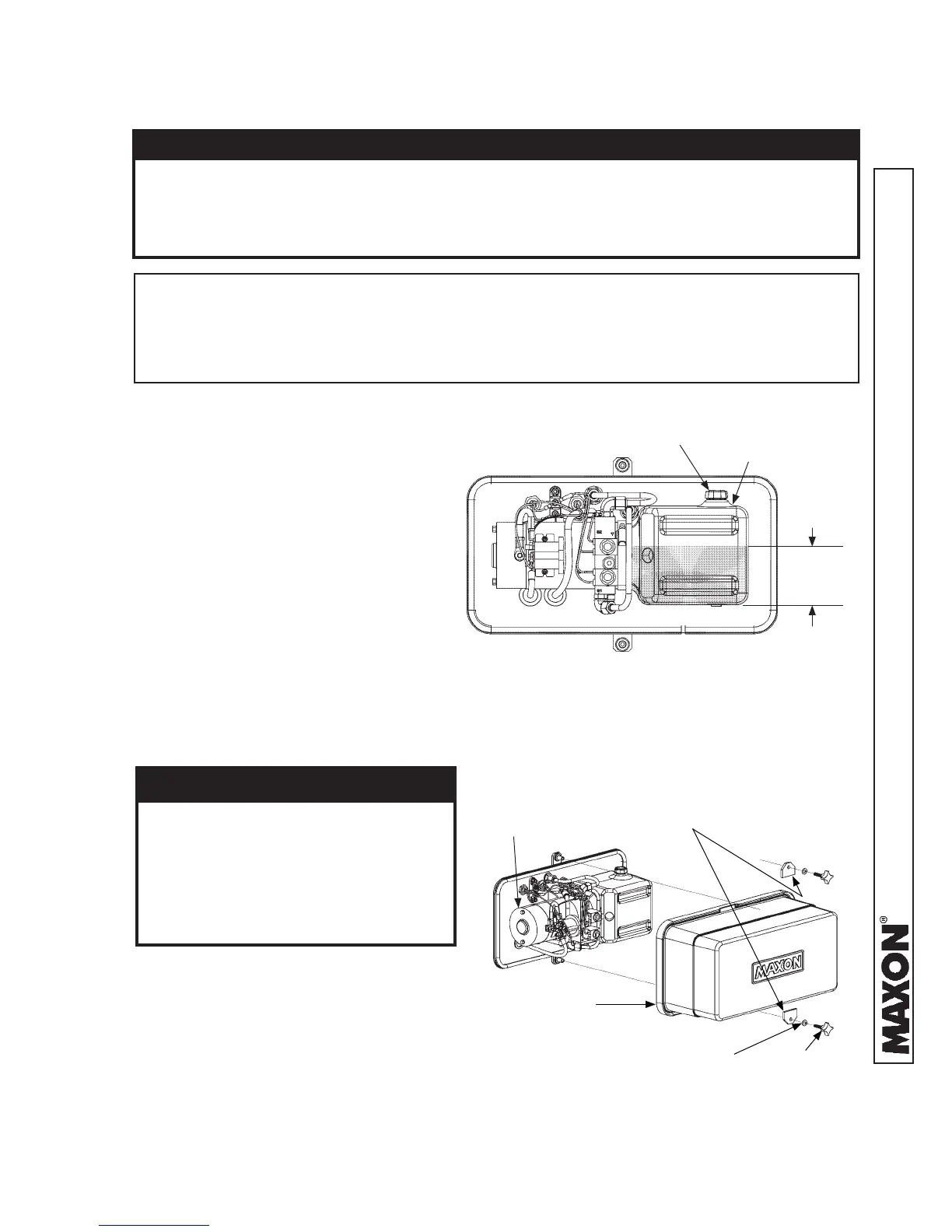

2. If needed, add fl uid to the reservoir

as follows. Pull out (no threads) fi ller

cap (FIG. 39-1). Fill the reservoir with

hydraulic fl uid to level shown in (FIG.

39-1). Reinstall fi ller cap (FIG. 39-1).

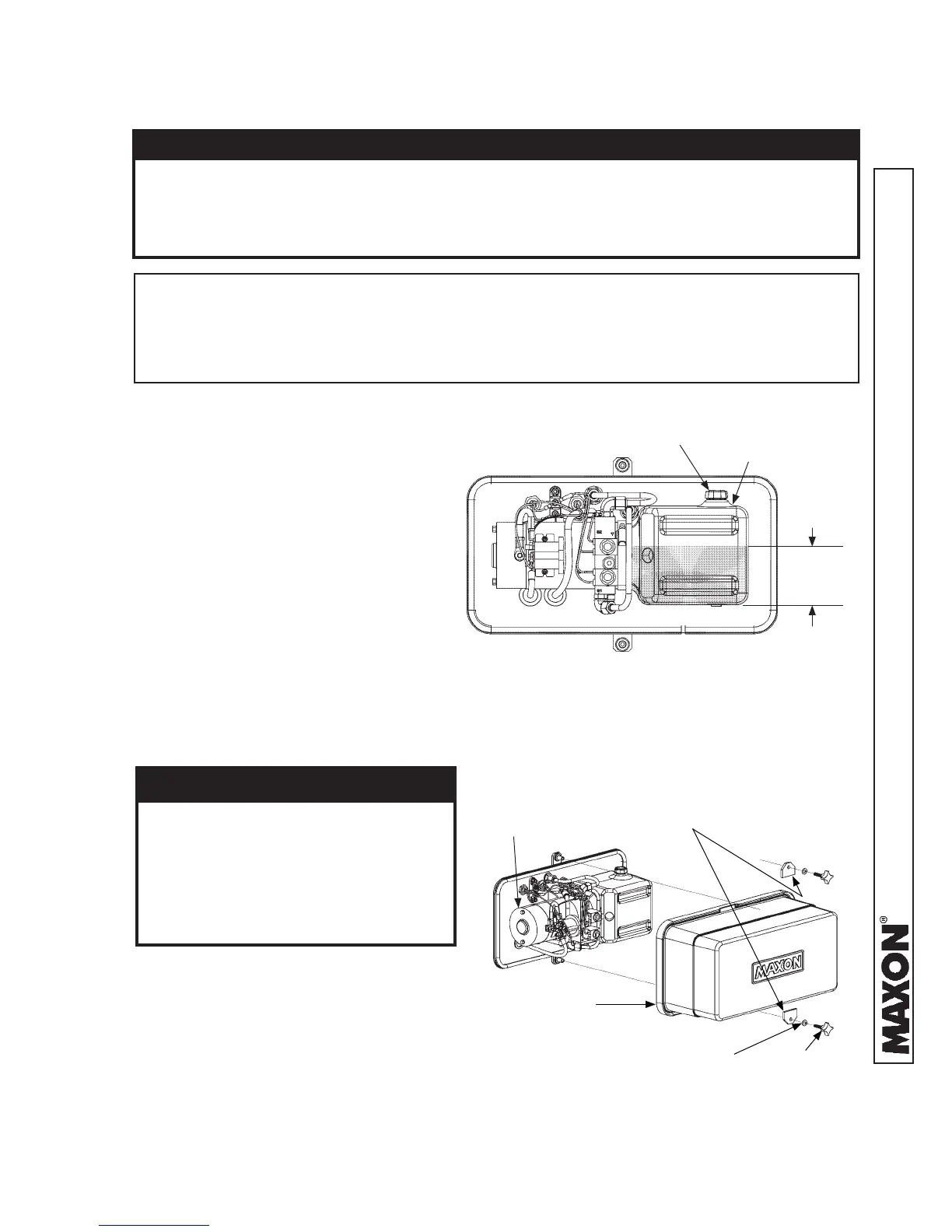

3. Bolt on the pump cover as shown in

FIG. 39-2. Hand tighten the threaded

cover knobs.

1. Check the hydraulic fl uid level in

reservoir as follows. With Liftgate

stowed, or platform at vehicle bed

height, level should be as shown in

FIG. 39-1.

CAUTION

Pump cover must be correctly se-

cured to prevent it from becoming

a hazard. To secure pump cover,

the long side of the holder fl ats

must butt against pump cover as

shown in the illustration.

LONGER SIDE OF

HOLDER FLATS BUTT

AGAINST COVER

BOLTING ON PUMP COVER

FIG. 39-2

PUMP

COVER

KNOB

(2 PLACES)

POWER UNIT

(REF)

FLAT WASHER

(2 PLACES)

POWER UNIT FLUID LEVEL

FIG. 39-1

FILLER

CAP

RESERVOIR

3”

Loading...

Loading...