33

3.3 PTO Shaft

3.3.1 PTO Setup & Adjustment (first use)

Equipment Required

Tape Measure

Marker Pen

The PTO of your machine will be delivered as it left the manufacturer, so will

require to be shortened to give the correct effective length between the machine

and the power take-off of the tractor.

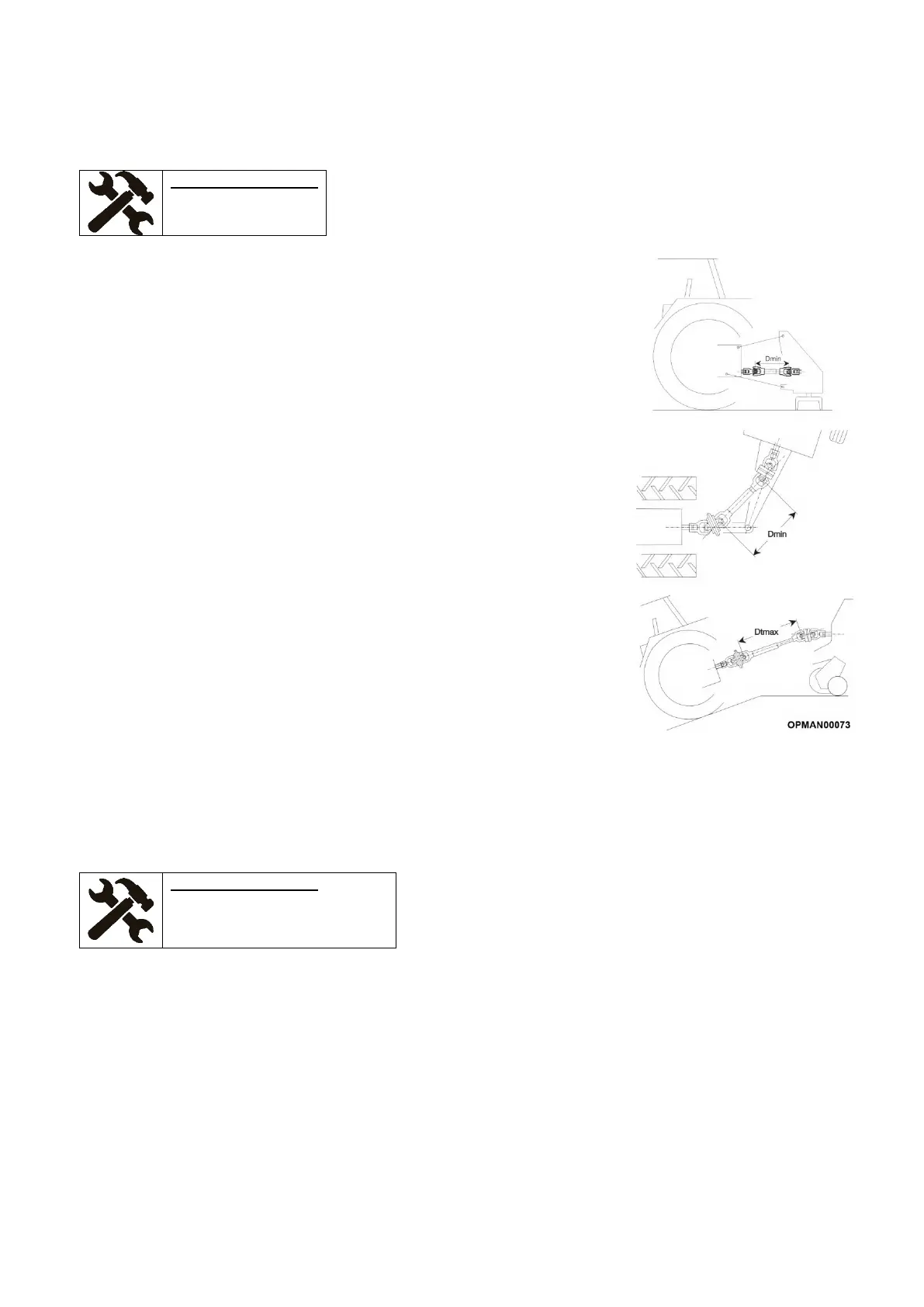

In order to determine the correct length of the finished driveline, hook the

machine to the tractor and proceed to install the two uncoupled/unprotected

semi-shafts to their respective tractor/machine PTO’s. For guidance on fitting

input shafts; see Section 4.5.1.

Place the tractor/machine in the position so the two halves of the shafts are at

the minimum distance between the two ends; see Figure 3.5. At this point,

verify any interference of the outer tube with the yoke inner tube and establish

how much the outer tube needs to be shortened.

On trailed machines, the minimum distance “Dmin” (see Figure 3.5), occurs

between the joints during steering. Verify that in the condition of maximum

extension “Dmax”, which generally occurs when the machine is aligned going

sleeply downslope, the coupling between the two tubes is still sufficient.

The input shaft should be shortened to ensure:

At least 25mm (1”) clearance at the shortest point (Dmin) between the

end of the shaft and the universal joint

At least 1/3 of the shafts length overlap engagement at the longest

point (Dmax) between the two CV tube halves

Figure 3.5 – Max/min Input Shaft Overlap

Check and ensure that the shaft has been sufficiently maintained and prepared before proceeding to use using

the machine following the guidance given in Section 5.2.2.

3.3.2 Bottoming Out Test

Equipment Required

Coloured tape

Tape measure

It is important to test whether the shaft has been sufficiently shortened to protect against “bottoming out” by:

3.3.2.1 Disconnecting the input PTO shaft and fully compress the two halves of the shaft together

3.3.2.2 Placing a piece of coloured tape on the inner shield 5mm (3/16”) away from the end of the outer shield

3.3.2.3 Reattach the PTO shaft between the tractor and machine

3.3.2.4 Slowly drive the tractor without the PTO shaft engaged and make the machine turn the tightest turn

possible and follow the most severe terrain expected

3.3.2.5 If at any point the outer shield end becomes any closer than 50mm (2”) away from the placed tape, then

shorten the PTO shaft and then test again

To effectively shorten and modify the input shaft; see Section 3.3.4.

Loading...

Loading...