46

Removal

Equipment Required

22mm (M14) socket or spanner

NLGI #2 Molybdenum Disulphide grease with paint brush/distributor

Removing the input shaft works in a reverse fashion from what is stated in the fitting section; by removing the

shaft from the tractor end first. Ensure that the PTO is disengaged, tractor engine is stopped, and the handbrake

is applied before proceeding to remove the shaft.

It is best practice, when removing the input shaft, to wipe a small quantity of grease (NLGI #2 Molybdenum

Disulphide) onto the splines of the exposed shaft end to prevent corrosion.

If the machine is not going to be used for an extended length of time the input shaft should be removed

completely and stored indoors to maintain its condition.

Proceed as follows:

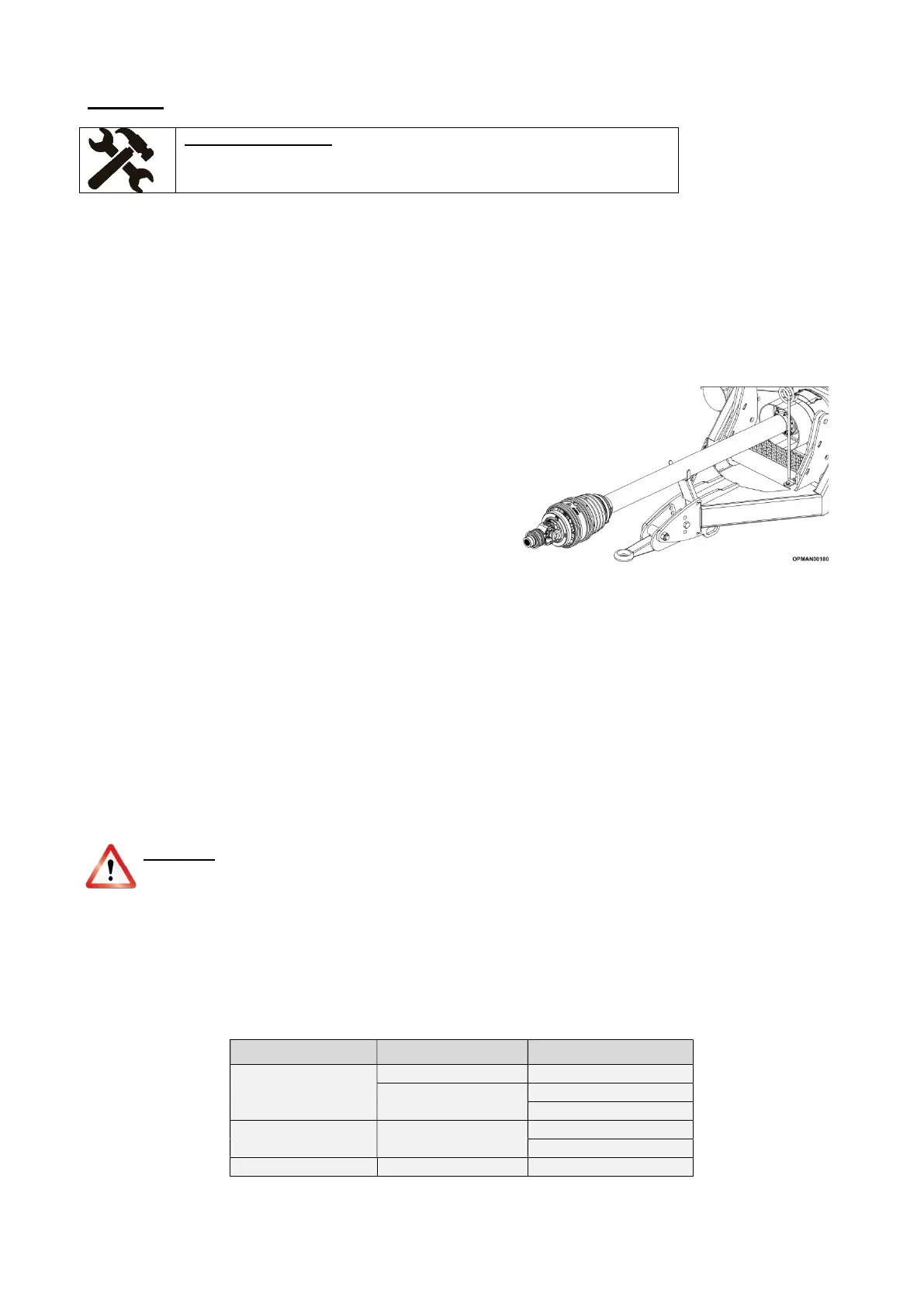

4.5.1.6 Pull the input shaft yoke collar back and pull back the

shaft off the output splined shaft of the tractor; see

Figure 4.10 (B).

4.5.1.7 If the shaft is not destined to be removed completely,

utilise the machines PTO support bracket to rest the

PTO shaft on; see Figure 4.14. This will ensure that

the shaft doesn’t get contaminated with dirt.

Figure 4.14 – PTO Support Bracket

4.5.1.8 To then completely remove the shaft, remove the taper pin, flat washer and nut from the machine end;

see Figure 4.11.

4.5.1.9 Refit the removed taper pin, flat washer and nut for safe keeping.

4.5.1.10 It is best practice, when removing the input shaft to wipe a small quantity of grease (NLGI #2

Molybdenum Disulphide) onto the splines at each end to aid later refitting to the tractor.

4.5.2 PTO Shaft Specifications

SR460/620/820 machines are primarily sold to operate at 1000 rpm, although the SR460 can be ordered and

specified to operate at 540 rpm.

DANGER! Do not use PTO adaptors to attach a non-matching implement driveline to a tractor PTO.

Use of an adaptor can double the operating speed of the implement resulting in excessive vibration,

thrown objects, blade/driveline failures due to changes in the machines design intended use. PTO

adaptors also increase the exposed working length increasing the probability of entanglement with

external objects. If the shaft is incorrect for the tractor; contact your local McConnel dealer for

assistance.

It is important to only operate at these speeds as a maximum and that the input PTO shaft is of the correct

specification for the machine and tractor. See Table 4.2 for input shaft speed options and the spline quantity

options.

Machine PTO Speed Number Of Splines

SR460

540 rpm 6

1000 rpm

6

21

SR620 1000 rpm

6

21

1000 rpm 20

Table 4.2 – Input Shaft/PTO Speed Options

Loading...

Loading...