45

Fitting - Machine End

Equipment Required

Torque wrench (see required settings in Torque Settings section)

22mm hex socket

NLGI #2 Molybdenum Disulphide grease with paint brush/distributor

Proceed as follows:

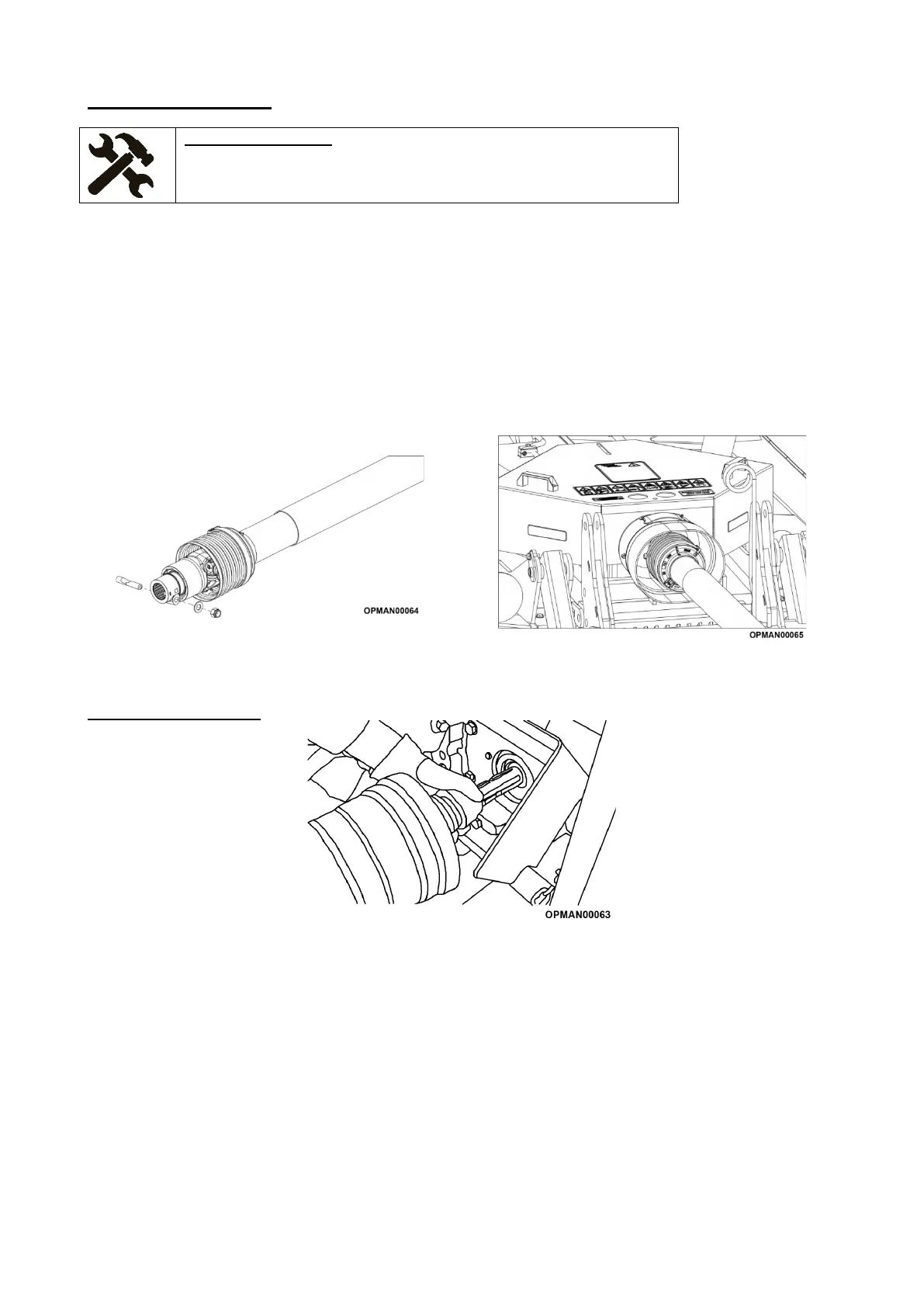

4.5.1.1 Proceed to remove the taper pin, flat washer and nut from the machine end of the input PTO shaft. See

Figure 4.11.

4.5.1.2 Install the input PTO shaft onto the splitter gearbox lining up the slot in the splitter gearbox shaft with

where the input shaft taper pin will be placed; see Figure 4.10 (A). Replace the removed taper pin, flat

washer and nut and tighten to a torque of 230Nm (170 ft/lbs).

It is best practice, when fitting the input shaft to wipe a small quantity of grease (NLGI #2 Molybdenum

Disulphide) onto the splines to aid assembly and later removal.

Figure 4.11 – Remove Taper Pin Figure 4.12 – Fit to Mower

Fitting - Tractor End

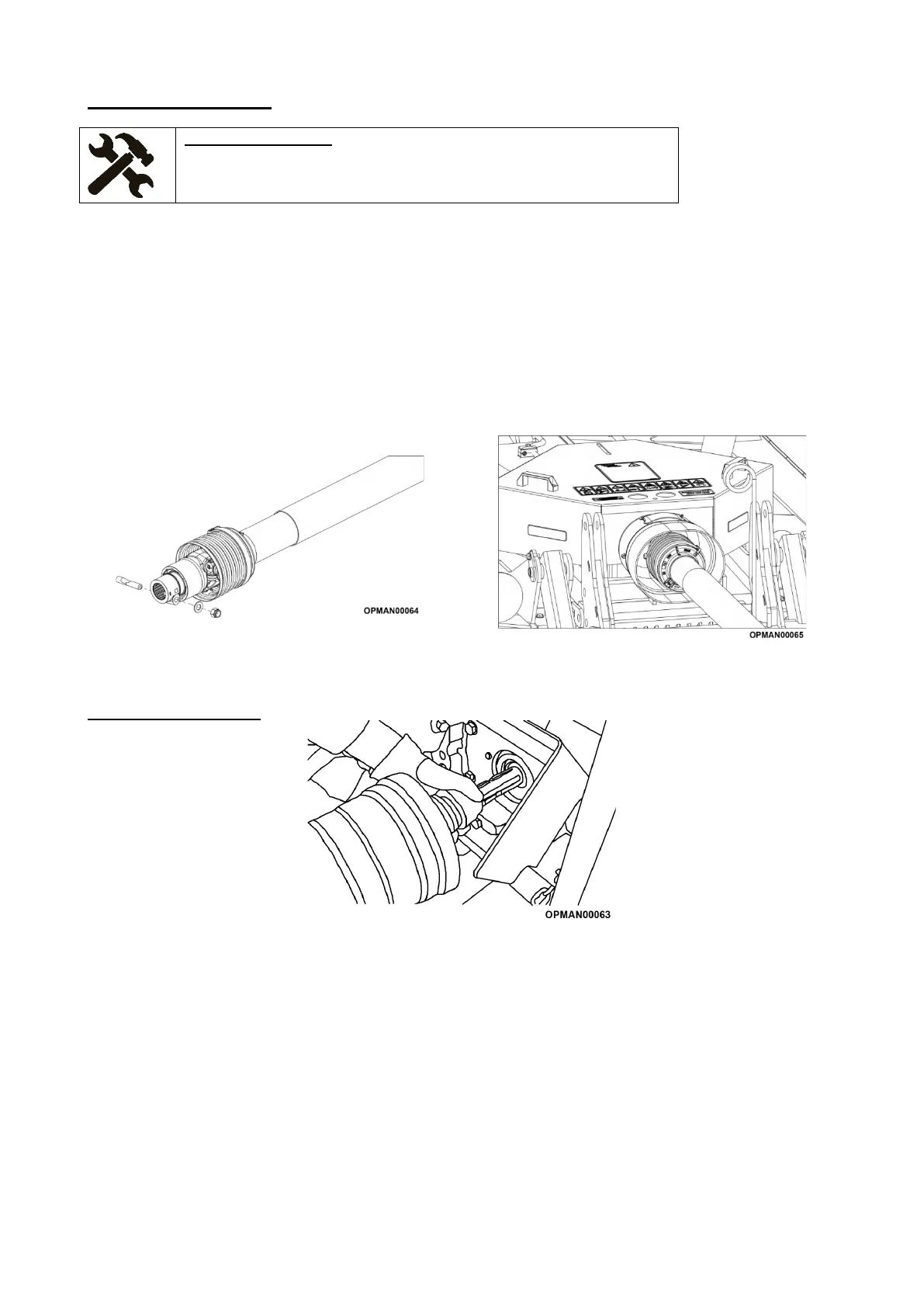

Figure 4.13 – Fit Input Shaft to Tractor

Proceed as follows:

4.5.1.3 Pull the input shaft yoke collar back and align the grooves and splines with those of the PTO output

shaft of the tractor; see Figure 4.10 (B).

4.5.1.4 Push the driveline yoke onto the tractor output PTO shaft, release the locking collar and position the

yoke of the input shaft until the locking collar balls are seated onto the tractors output PTO shaft; see

Figure 4.10 (C).

4.5.1.5 To ensure that the input PTO shaft is secure, push and pull the shaft back and forth several times.

It is best practice, when fitting the input shaft to wipe a small quantity of grease (NLGI #2 Molybdenum

Disulphide) onto the splines to aid assembly and later removal.

Loading...

Loading...