84

IMPORTANT: Do not over-tighten the bolts; this may endanger the function of the clutch.

IMPORTANT: McConnel recommends to not modify the torque settings given in Section 5.4.3. Damages to

implement, driveline or tractor may occur. McConnel declines all responsibility for damage to

implement, driveline or tractor caused by modifying any of the slip clutch settings on SR460/620/820

machines in any other way than described in this manual. If you are unsure of the procedure, or

need additional assistance, please contact your local McConnel dealer, qualified service centre or

McConnel.

5.4.2 Freeing Seized Clutch Plates

Equipment Required

Digital Vernier caliper/micrometre

2 x 17mm hex sockets/spanners

If the machine has been laid up for any length of time, there is a risk of the clutch plates rusting and

seizing together. Never operate the machine if it is in/potentially in this condition, as there will be no protection

to the driveline and gearboxes against shock loading.

To free the clutch plates:

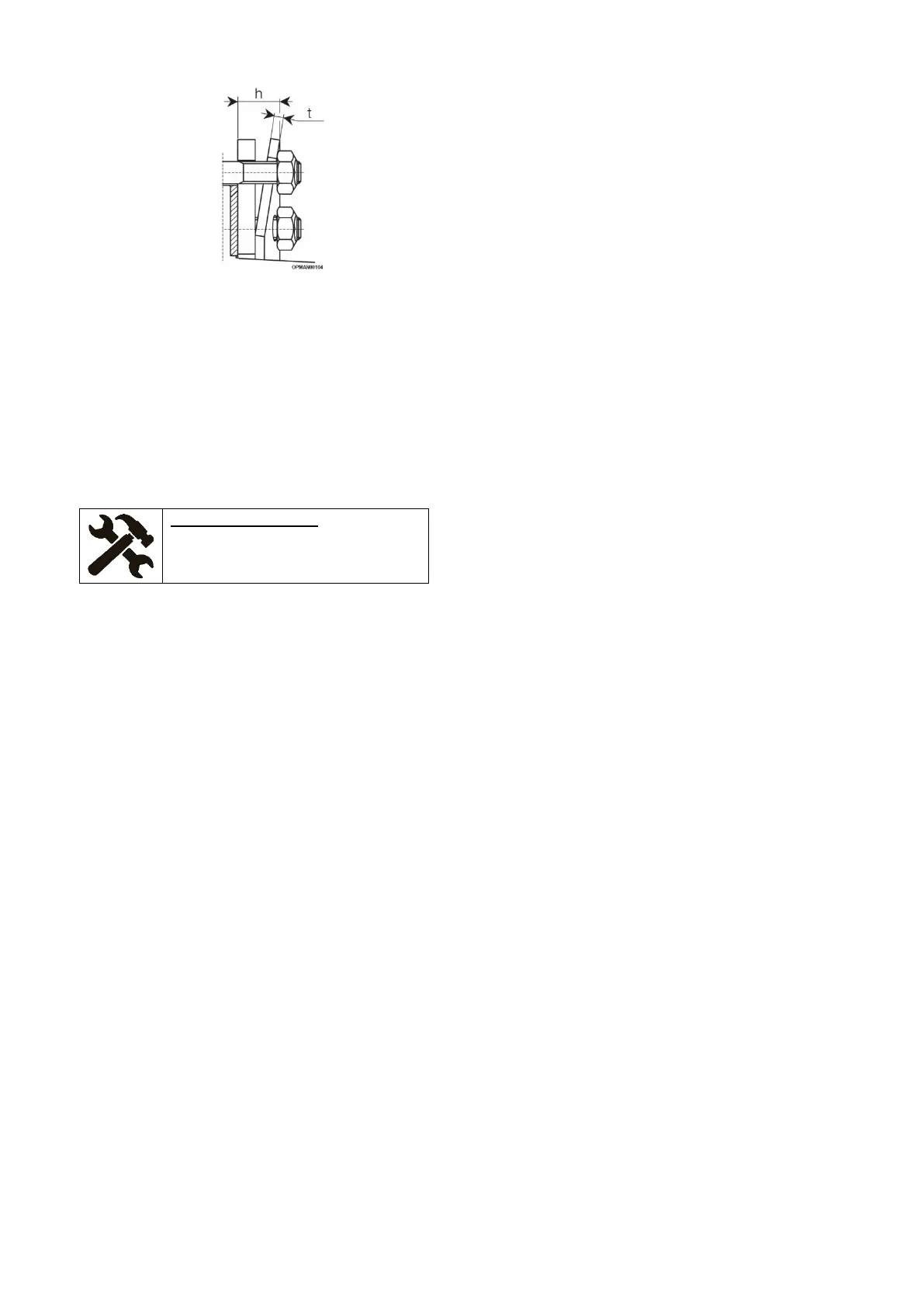

5.4.2.1 Slacken all compression spring bolts off the clutch plates; see Section 5.4.1.2.

5.4.2.2 Mark the outer plates in order to give a visual reference to if the clutch plates have freed or moved.

5.4.2.3 Run the machine temporarily in an aim to cause the clutch to slip with the tractor speed at around 1000

rpm.

5.4.2.4 Retighten the compression bolts to the correct distance for the particular clutch in question; see Section

5.4.1.5 to 5.4.1.9.

IMPORTANT: Do not over-tighten the bolts; this may endanger the function of the clutch.

If you are unsure of the procedure, or need additional assistance, please contact your local McConnel

dealer, qualified service centre or McConnel.

As a procedure to stop the above listed problem occurring, McConnel recommends that slip clutches are

released when the machine is laid up for any longer than 7 days.

Loading...

Loading...