36

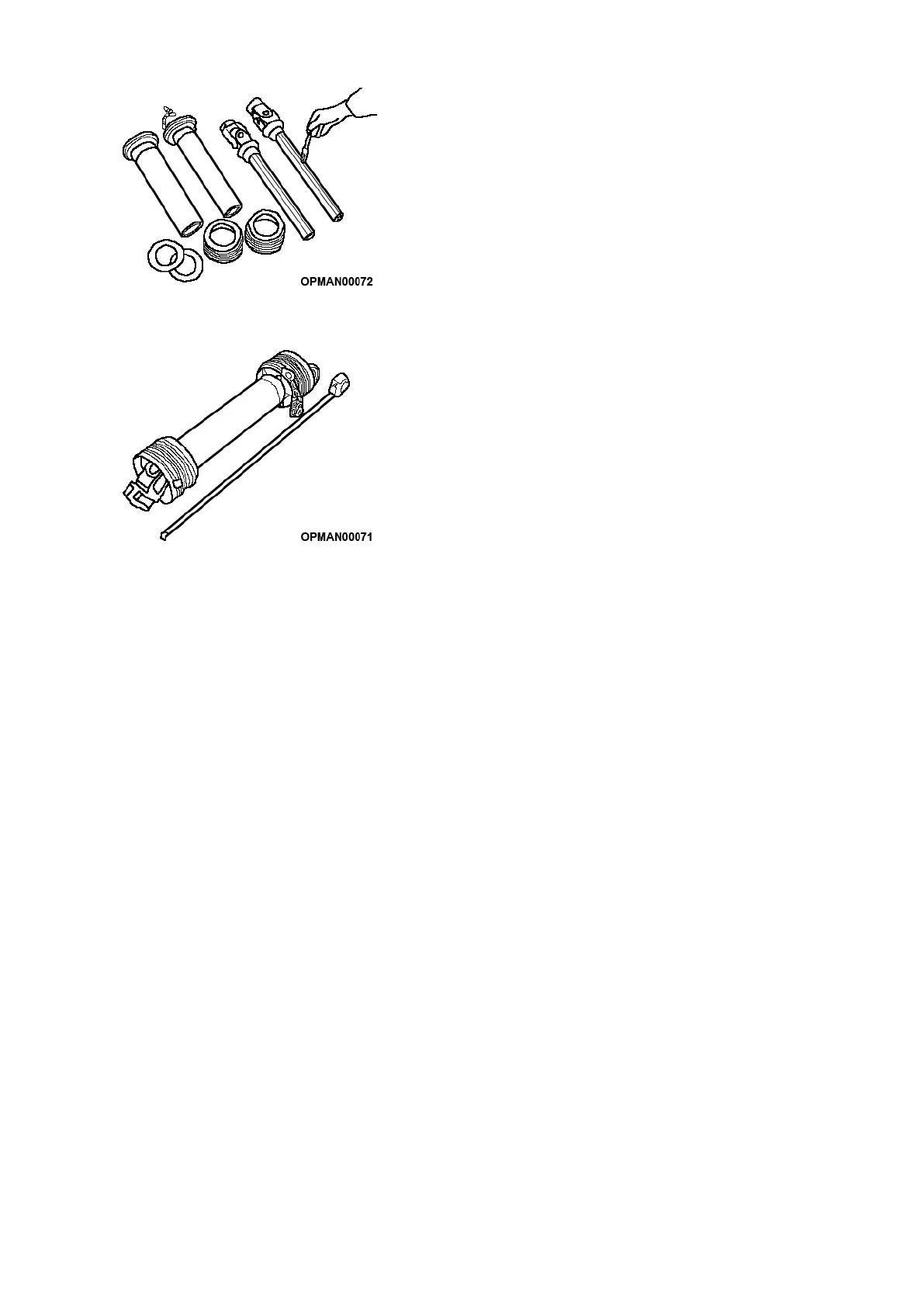

Figure 3.10

3.3.4.5 Grease the internal drive tube. Reassemble the shield on

the driveshaft.

NOTE: SFT drivelines with 4-tooth profiles must be

reinstalled in such a way that the grease fittings on the

cross kit bearings are aligned.

3.3.4.6 Check the length of the driveshaft at the minimum and

maximum positions of the machine. See Figure 3.5 for

guidance on Dmin/Dmax lengths.

If further adjustment is required; repeat the process.

3.3.5 Fitting The PTO Shaft

For guidance on fitting the Power Take Off (PTO) shaft between the machine and tractor; see Section 4.5

3.4 Wheels & Tyre Installation

There may be on some occasions, dependent on the type of delivery chosen for the machine to be delivered to

the dealer/customer where wheels and tyres could be removed from the machine and will be required to be

refitted to the machine when it arrives and before its first use. An example of this could be if the machine has

been delivered inside a container.

For guidance on removing and installing tyres see Section 5.7.

Loading...

Loading...