83

Reassembly

The following section refers to the reassembly operations of a slip clutch. This procedure can be carried out in

the same fashion for either of the slip clutches shown in the Disassembly section.

Equipment Required

Digital Vernier caliper/micrometre

19mm hex sockets/spanner

2 x 17mm hex sockets/spanners

NLGI #2 Molybdenum Disulphide grease with paint brush/distributor

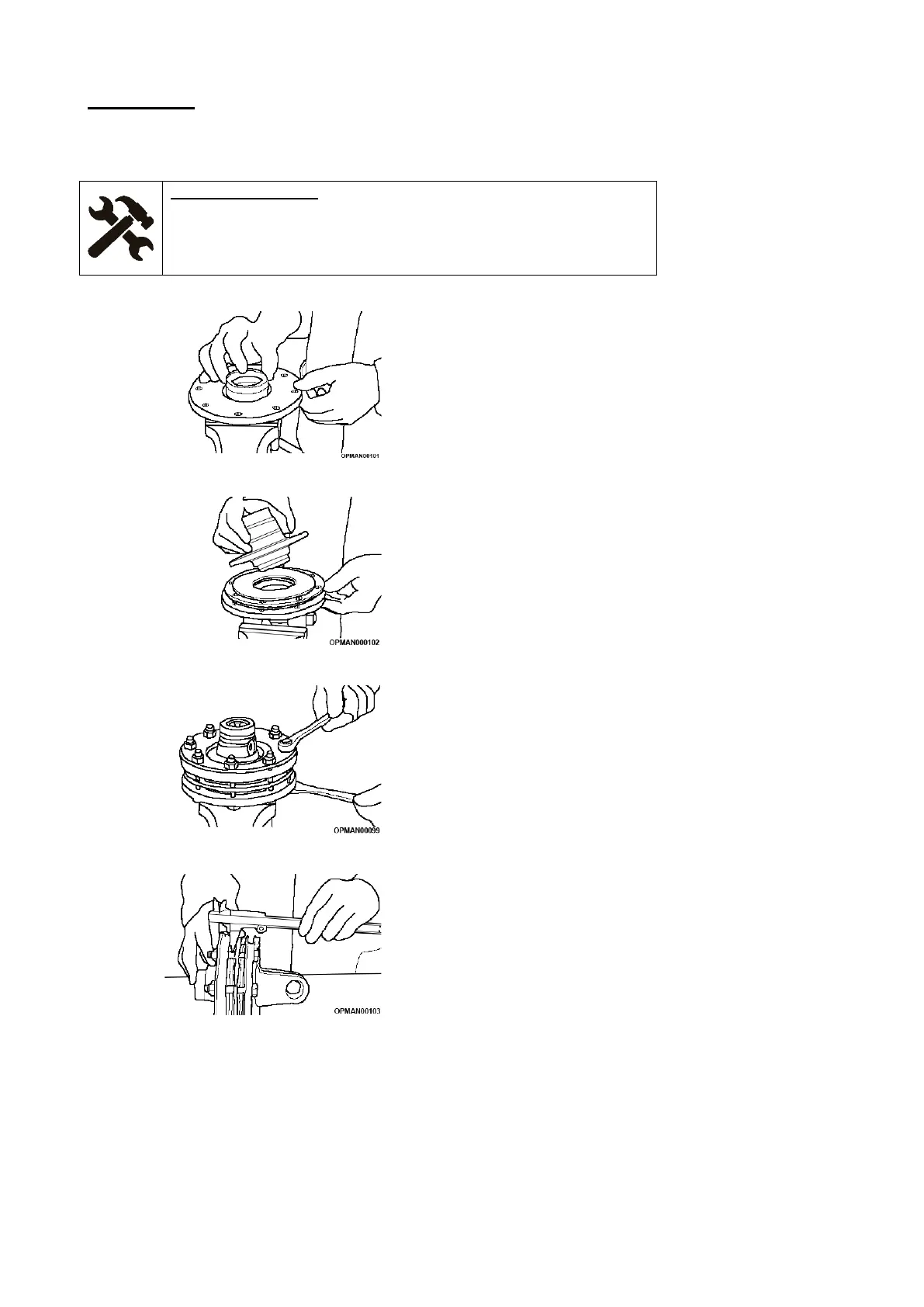

5.4.1.5 Apply a film of grease on the bushing surfaces

and insert it into the flange yoke. Avoid

excessive grease on the bushing

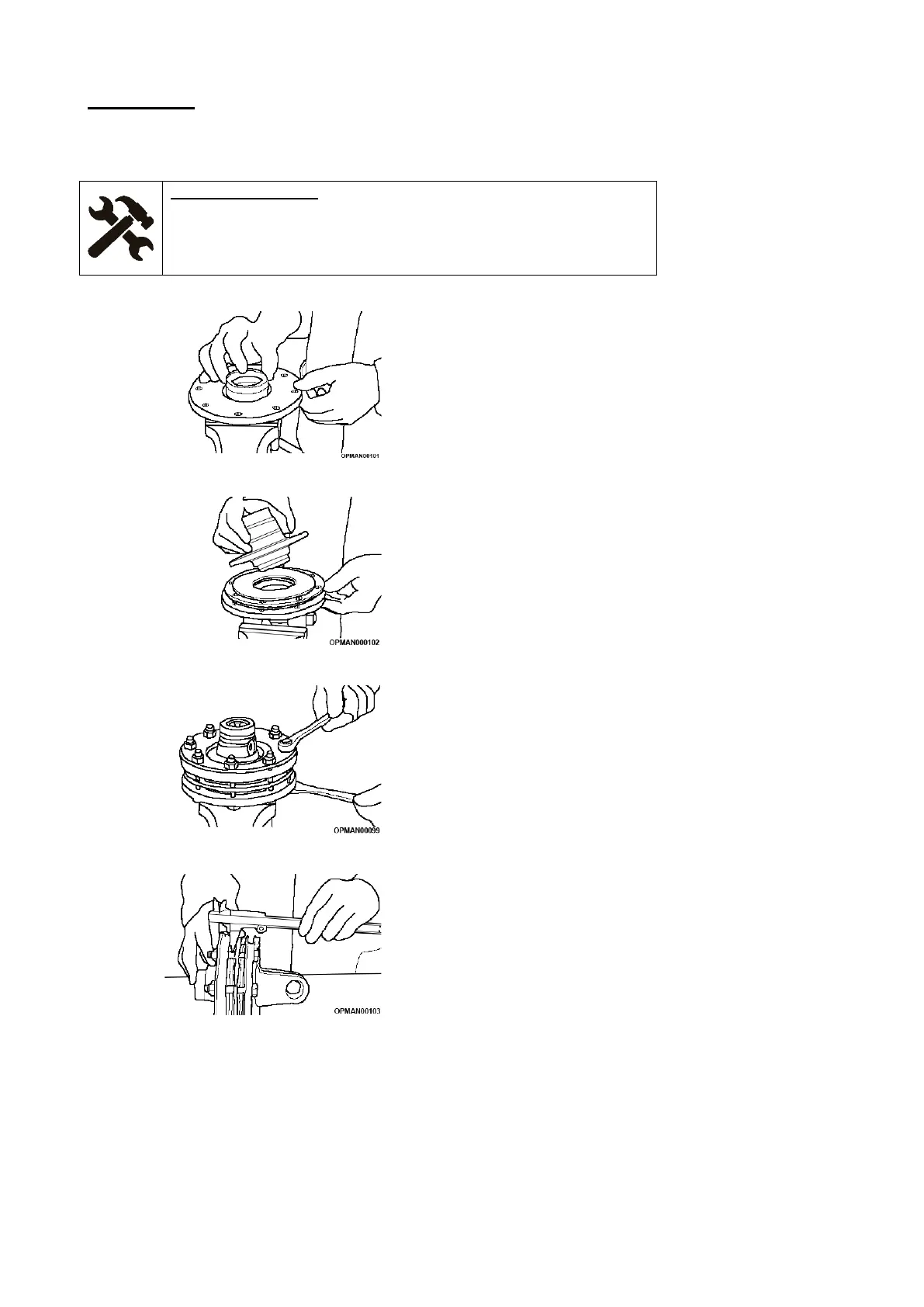

5.4.1.6 Assemble in sequence the other parts as

shown in Figure 5.36 and Figure 5.37,

depending on the PTO shaft in question

5.4.1.7 Insert the 8 screw with their heads on the

flange yoke side

5.4.1.8 Turn all the nuts in contact with the spring

5.4.1.9 Tight progressively the bolts (e.g. half a turn

per time) in order to uniformly compress the

Belleville spring to its required compression

“h”; see Figure 5.45

For slip clutch settings see Section 5.4.3 and select

the correct machine/particular shaft required. The

clutch setting is listed under column “h”

Loading...

Loading...