52

Coarse Adjustment (rarely required)

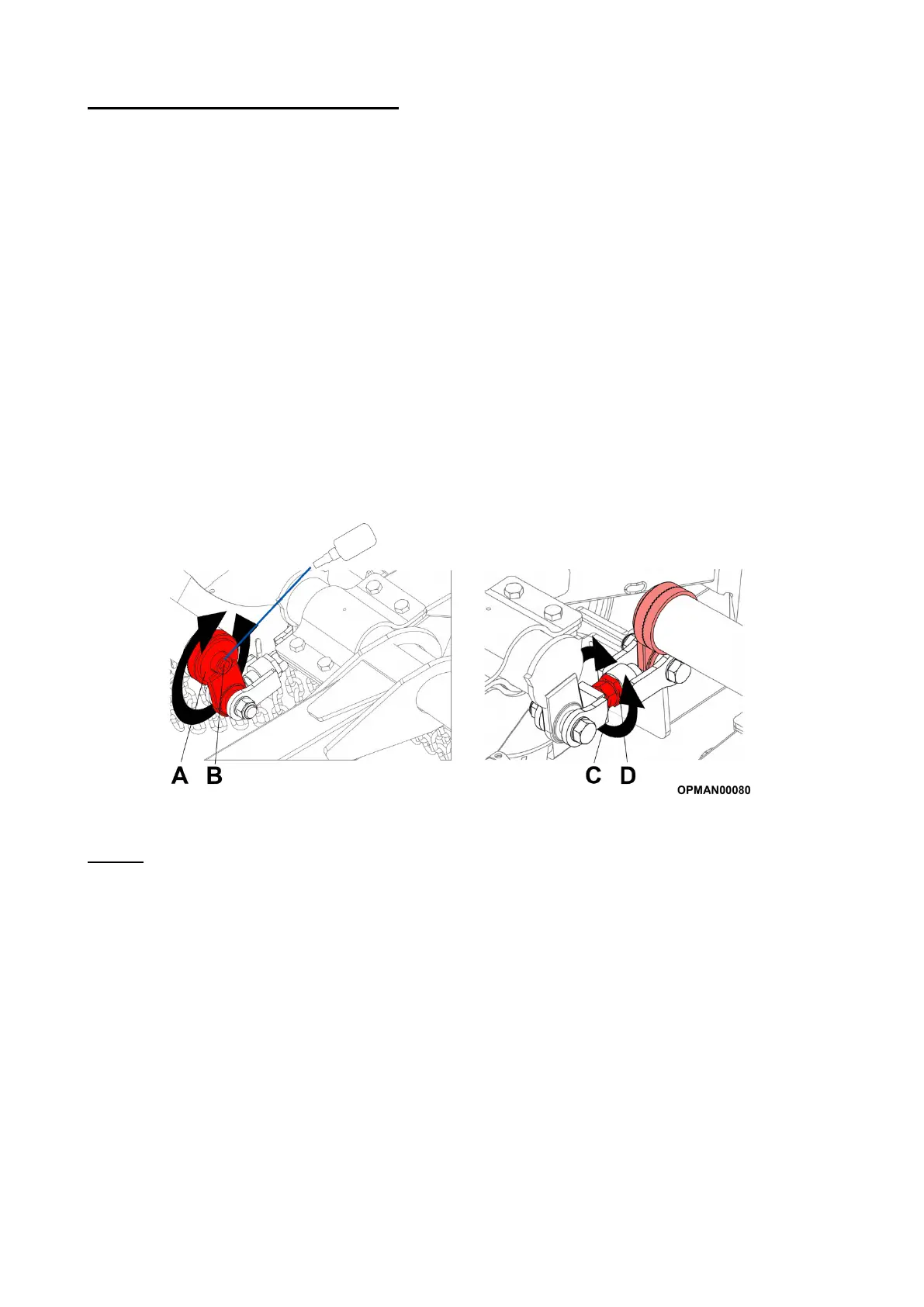

With reference to Figure 4.24, coarse adjustment is made by:

4.7.2.4 Loosen/remove the Allen bolt (B) in order to release the teeth engagement of the serrated disc located

on each wing axle (A).

4.7.2.5 Move the ball end rearwards to raise wing and away to lower it.

4.7.2.6 Ensure the teeth are fully engage before tightening.

4.7.2.7 Place a small quantity of medium duty removable lock-tight on the Allen bolt and torque to 500Nm to

secure it.

4.7.2.8 Shunt the machine backwards and forwards a couple of times to ensure suspension and all pivots are

settled into the working positions.

4.7.2.9 Recheck working heights and repeat process if required.

IMPORTANT: Adjust both wings by the same amount to ensure a level cut.

Figure 4.24 – SR460/620 Coarse & Fine Wing Adjustment

SR820

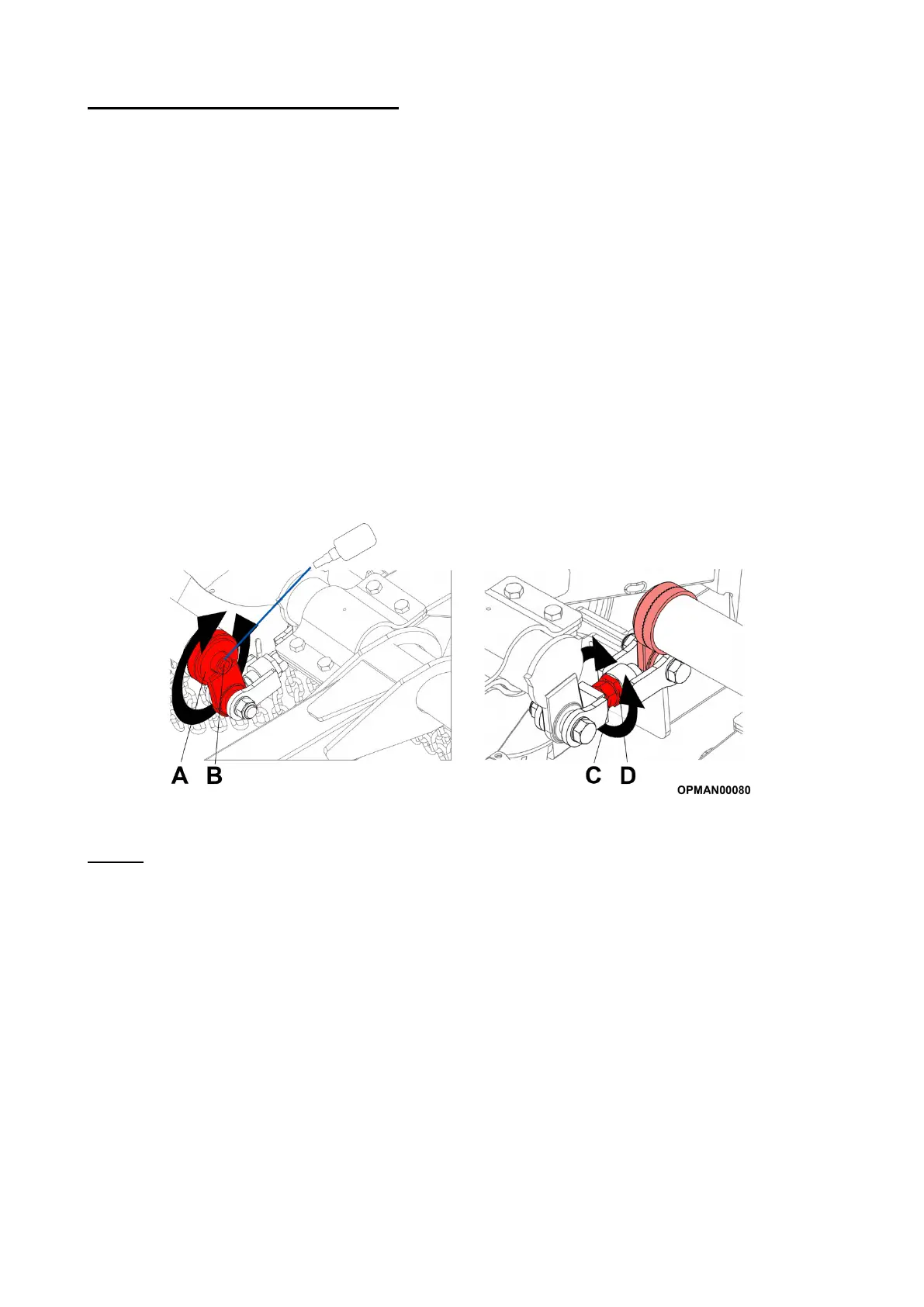

With reference to Figure 4.25 to adjust the wings:

4.7.2.10 Release the locking star nut (A).

4.7.2.11 Using the turnbuckle located between the axles (B)

Lengthen the exposed amount of thread to lower the wing and shorten to raise the wing.

4.7.2.12 Retighten the locking star nut to preserve the adjustment.

4.7.2.13 Shunt the machine backwards and forwards a couple of times to ensure suspension and all pivots are

settled into the working positions.

4.7.2.14 Recheck working heights and repeat process if required.

IMPORTANT: Adjust both wings by the same amount to ensure a level cut.

Loading...

Loading...