B

TIm

BE

..

Ul

AXI.E-

~

_

The

bearings

of

the

differential and

crown

wheel

assembly

are

carried

in recesses machined in

the

axle

casing and cover. which

are

bolted

together.

and,

since no

rnspectic

nape

rtu res

are

provided, all

adjustments

have

to

be

carried

out

by

pre-

measurement

in

conjunction

with

special

gauges.

Adjustment

of

the

position of

both

the

crown

wheel

and

the

pinion in

the

axle Is effected by distance-

pieces, which

are

selected on initial assembly, and

there

is no

other

provision for

adjustments.

The

crown

wheel

and pinions

are

only supplied in pairs

as

heretofore.

The

use

of

Hypold gears enables a much larger

pinion

to

be used, provldlng

more

silent running and

a

greatly

increased life.

The

rear

brake

gear

is of

the

normal

two-shoe

type,

operated

hydraulically

from

the

brake pedal and also

mechanically by

hand-operated

mechanism actuating

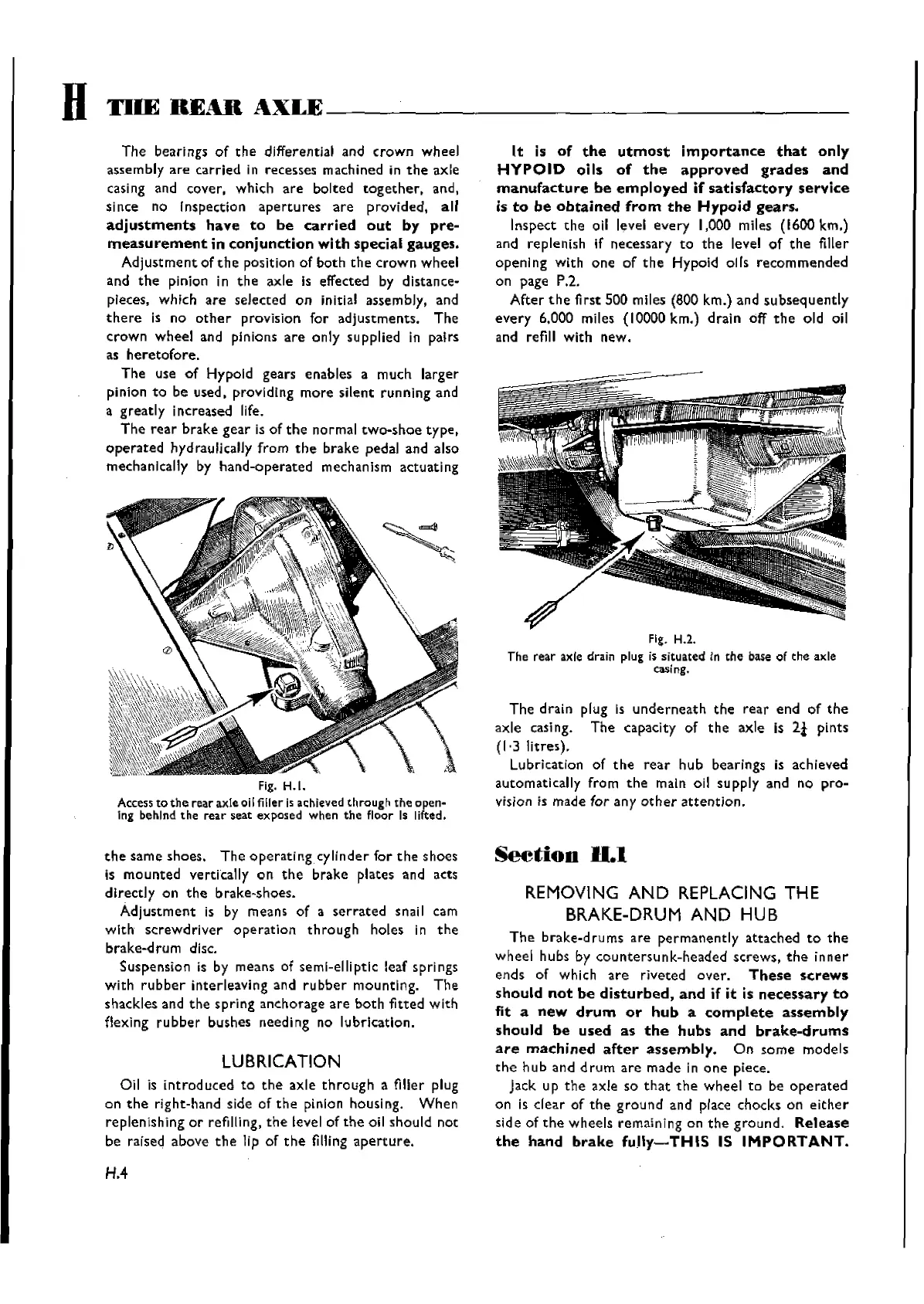

Fig.

H.I.

Access

to the rearaxleoiIfi Ilerisachieved th

rough

the open-

Ing

behlnd tile rear seat exposed when tile floor Is lifted.

the

same shoes.

The

operatingcylinder

for

the

shoes

Is

mounted

vertically on

the

brake plates and acts

directly

on

the

brake-shoes.

Adjustment

is by means of a

serrated

snail cam

with

screwdriver

operation

through

holes in

the

brake-drum

disc.

Suspension is by means of seml-elli ptlc leaf spri ngs

with

rubber

interleaving and

rubber

mounting.

The

shackles and

the

spring

anchorage

are

both

titted

with

fleXing ru

bber

bushes needi ng no lubrication.

LUBRICATION

Oil is

introduced

to

the

axle

through

a filler plug

on

the

right-hand side of

the

pinion housing.

When

replenishing

or

refilling,

the

level of

the

oil should not

be raised above

the

lip of

the

filling

aperture.

H..4

It

is

of

the

utmost

importance

that

only

HYPOID

oils

of

the

approved

grades

and

manufacture

be

employed

if

satisfactory

service

is

to

be

obtained

from

the

Hypoid

gears.

Inspect

the

oil level

every

1,000

miles (1600km.)

and replenish If necessary to

the

level

of

the

filler

opening

with

one

of

the

Hypold oils

recommended

on page

P.2.

After

the

ti

rst

500 miles (800 km.) and

subsequently

every

6.000 miles (10000 krn.)

drain

off

the

old oil

and refill

with

new.

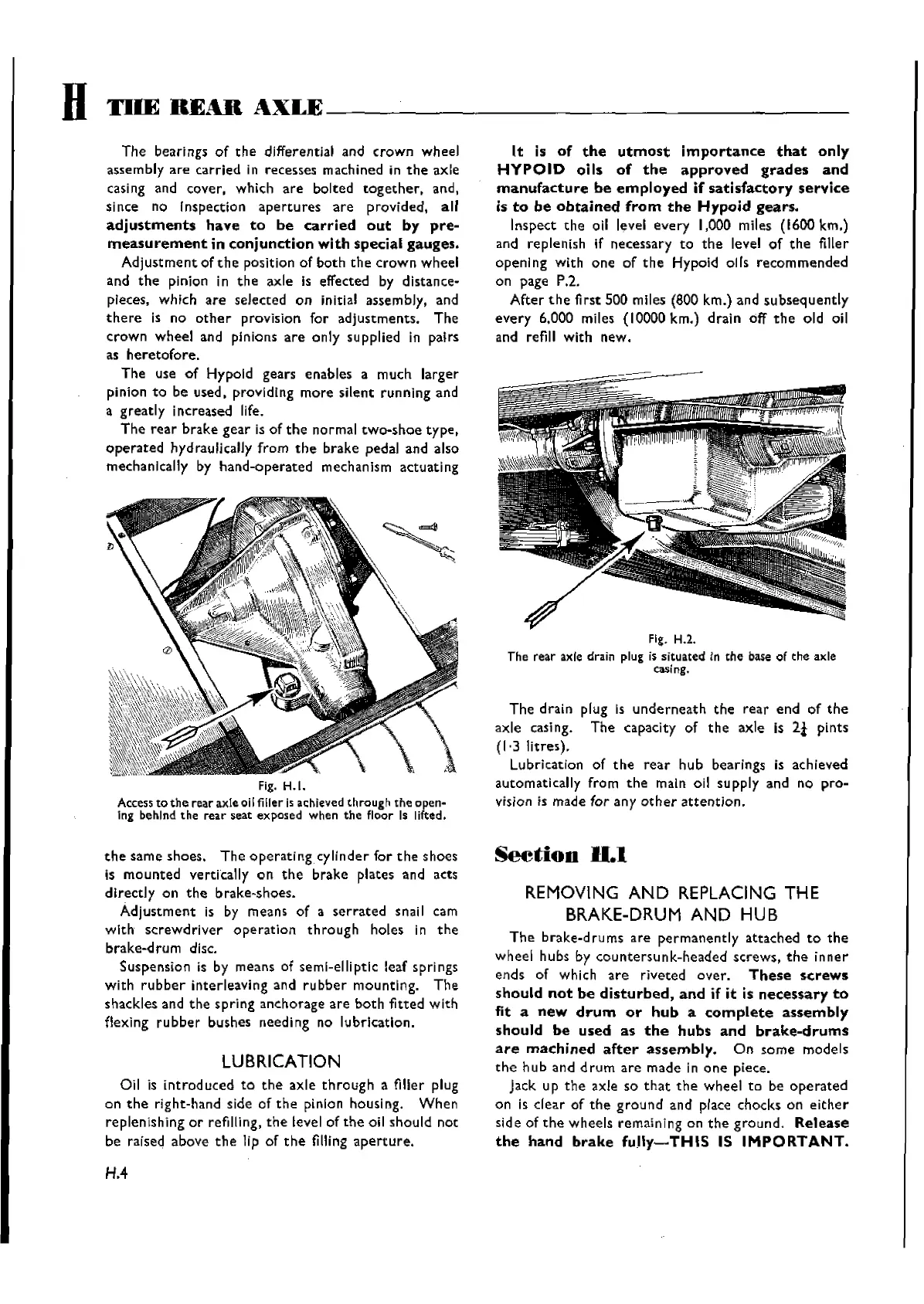

Fig. H.2.

The rear

axle

drain

plug

is situated in the

base

of the axle

casing.

The

drain plug Is

underneath

the

rear

end

of

the

axle casing.

The

capacity of

the

axle is

2!

pints

(1'3

litres).

Lubrication of

the

rear

hub bearings is achieved

automatically from

the

main oil supply and no

pro-

vision is made for any

other

attention.

Section

H.l

REMOVING

AND

REPLACING THE

BRAKE-DRUM

AND

HUB

The

brake-drums

are

permanently

attached

to

the

wheel

hubs by

countersu

nk-headed

screws,

the

in

ner

ends of which

are

riveted

over.

These

screws

should

not

be

disturbed,

and

if

it

is

necessary

to

fit

a

new

drum

or

hub

a

complete

assembly

should

be

used

as

the

hubs

and

brake-drums

are

machined

after

assembly.

On

some

models

the

hub and

drum

are

made

in

one

piece.

Jack up

the

axle so

that

the

wheel

to be

operated

on is

dear

of

the

ground

and place chocks on

either

side of

the

wheels remaining on

the

ground.

Release

the

hand

brake

fuHy-THIS

IS

IMPORTANT.

Wishvilles Classic

Automobile Library

Loading...

Loading...