H

TIlE

REAR

AXLE--

--

-

----------------

-------_.---

Section

B.3

REMOVING

AND

REPLACING A REAR

AXLE HALF·SHAFT

Jack u

pthe

axle as

outll

ned in Section

H.I,

or

raise

the

rear

of

the

car

with

a sling

attached

to

the

bumper

supports.

Remove

the

wheel

as in Section

H.I.

See

that

the

hand

brake

is

fully

released.

Remove

the

hub and

brake-drum

assembly as in

Section

H.!.

Remove

the

brake

plate and

shoe

assembly as In

Section H.2.

Withdraw

the

split collar

from

the

axle half-shaft.

Fit

the

special

tool

(Part

No.

68823)

to

the

end

of

the

axle

shaft and, using

the

sliding impact

weight,

release

the

shaft

complete

with

bearing, housing and

oil seal.

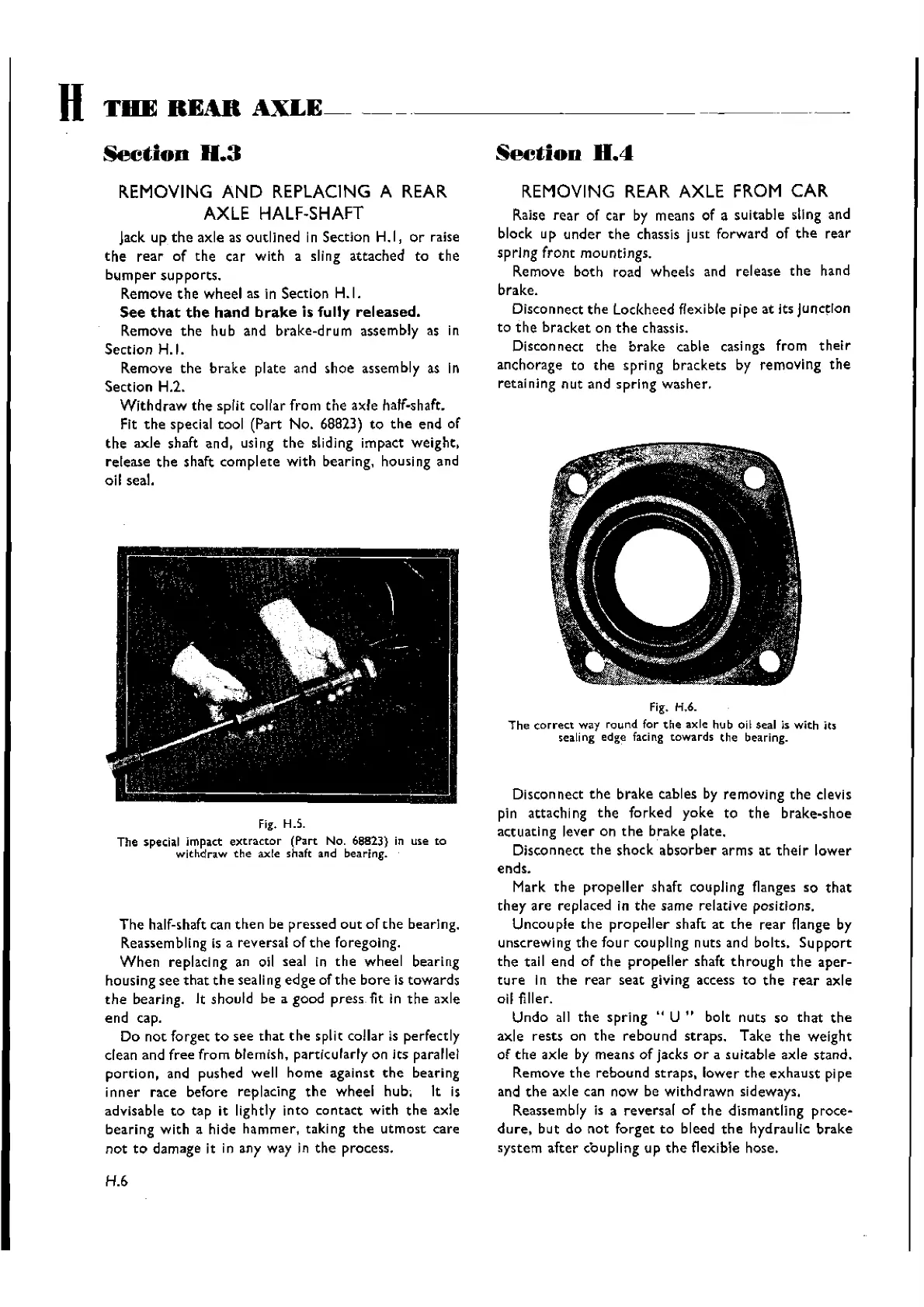

fig.

H.5.

The

special Impact

extractor

(Part

No. 68823) in use

to

withdraw

the

axle shaft and bearing,

The

half-shaft can

then

be pressed

out

of

the

bearIng.

Reassem b

Iing is a reversal of

the

foregolng.

When

replacing an oil seal in

the

wheel

bearing

housing see

that

the

sealing

edge

of

the

bore

is

towards

the

bearing. It should be a

good

press fit In

the

axle

end

cap.

Do

not

forget

to

see

that

the

split collar is perfectly

dean

and free

from

blemish, particularly on its parallel

portion,

and pushed well

home

against

the

bearing

inner

race before replacing

the

wheel

hub; It is

advisable

to

tap it lightly

into

contact

with

the

axle

bearing

with

a hide

hammer,

taking

the

utmost

care

not

to

damage it in any way in

the

process.

H.6

Seetion

H.4

REMOVING REAR AXLE FROM CAR

Raise

rear

of

car by means of a suitable sling and

block up

under

the

chassis just

forward

of

the

rear

spring

front

mountings.

Remove

both

road wheels and release

the

hand

brake.

Disconnect

the

Lockheed flexible pipe at its [uncclon

to

the

bracket

on

the

chassis.

Disconnect

the

brake

cable casings from

their

anchorage to

the

spring

brackets by

removing

the

retaining

nut

and

spring

washer.

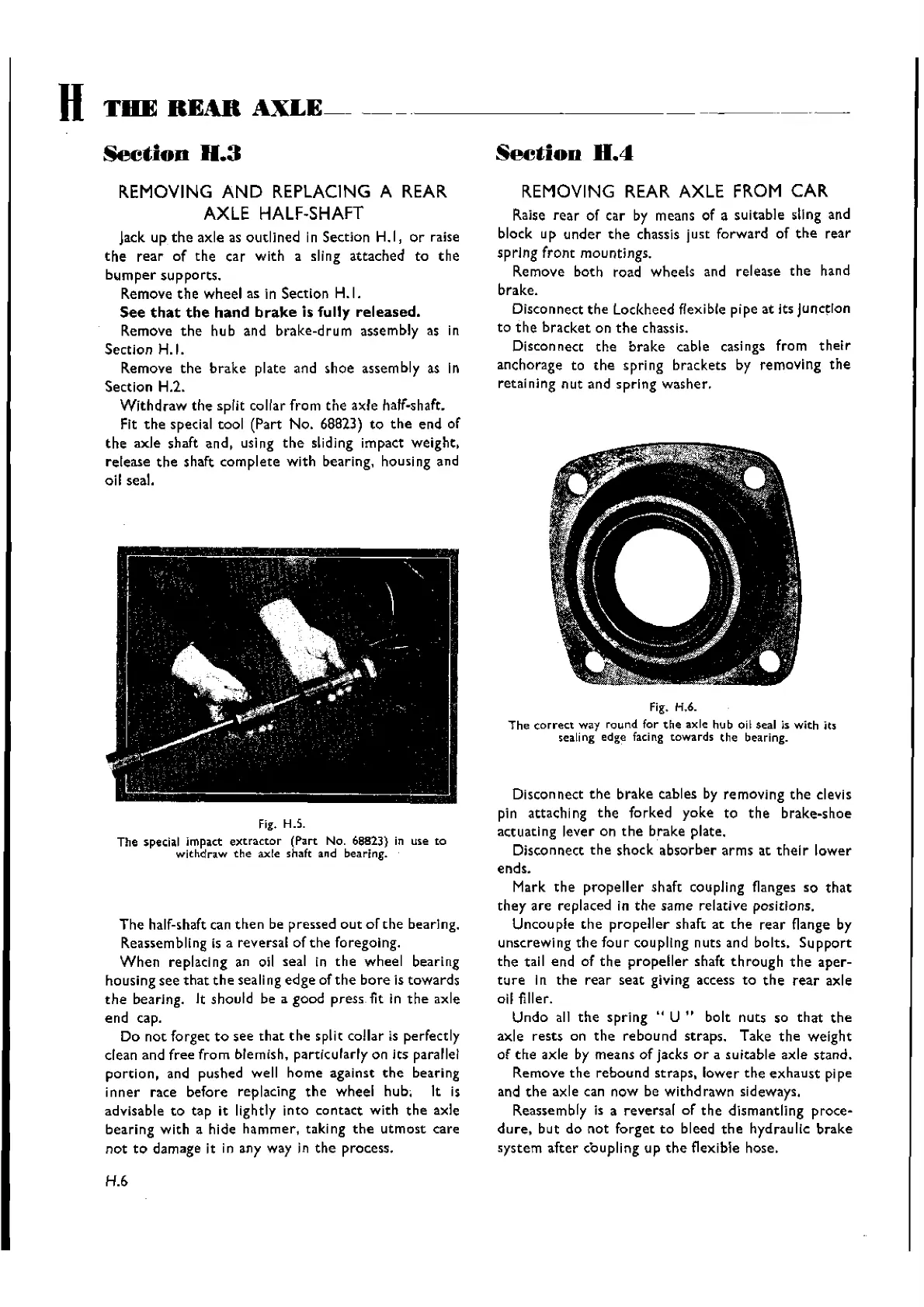

Fig. H.6.

The

correct

way

round

for

the

axle hub oil seal is

with

Its

sealing edge

fad ng

towards

the bearing.

Disconnect

the

brake

cables by

removing

the

clevis

pin attaching

the

forked

yoke

to

the

brake-shoe

actuatlng lever on

the

brake

plate.

Disconnect

the

shock

absorber

arms

at

their

lower

ends.

Mark

the

propeller

shaft coupling flanges so

that

they

are

replaced in

the

same relative positions.

Uncoupie

the

propeller

shaft

at

the

rear

flange by

unscrewing

the

four

coupling nuts and bolts.

Support

the

tail

end

of

the

propeller

shaft

through

the

aper-

tu re in

the

rear

seat

giving access

to

th e

rear

axle

oil filler.

Undo

all

the

spring

..

U"

bolt

nuts so

that

the

axle

rests

on

the

rebound

straps. Take

the

weight

of

the

axle by means

of

jacks

or

a

suitable

axle

stand.

Remove

the

rebound

straps,

lower

the

exhaust

pipe

and

the

axle can

now

be

withdrawn

Sideways.

Reassembly is a reversal

of

the

dismantling

proce-

dure,

but

do

not

forget

to

bleed

the

hydraulic

brake

system

after

cbupling up

the

flexible hose.

Wishvilles Classic

Automobile Library

Loading...

Loading...