N ELECTRICAL

EqUIPMENT-~--

commutator

end

bracket

and

remove

the

bracket

from

the

dynamo yoke.

The

driving end bracket,

together

with

the

arrna-

cure, can now be lifted

out

of

the

yoke.

The

driving end

bracket

which, on removal from

the

yoke, has

withdrawn

with It

the

armature

and

armature

shaft ball bearing. need

not

be

separated

from

the

shaft unless

the

bearing is suspected and

requires

examination, in which

event

the

armature

should be

removed from

the

end

bracket

by means of a hand

press.

Seetlon

N.5

SERVICING THE

DYNAMO

Brushes

Test

if

the

brushes

are

sticking. Clean

them

with

petrol

and. If necessary, ease

the

sides by lightly

pollsh[ng with a

smooth

file. Replace

the

brushes in

their orlgl nal positlo ns.

Test

the

brush spring tension with a

spring

scale if

available. The

correct

tension ls 20/25 oz.

(567{709

grams). Fit a new spring if

the

tension Is low.

If

the

brushes

are

worn

so

that

the

flexible is exposed

on

the

running face, new brushes must be fitted.

Brushes

are

pre-formed so

that

bedding

to

the

com-

mutator

is unnecessary.

Commutator

A

commutator

In good condition will be

smooth

and

free from pits

or

burned

spots. Clean

the

com-

mutator

with a petrol-moistened cloth. If this Is

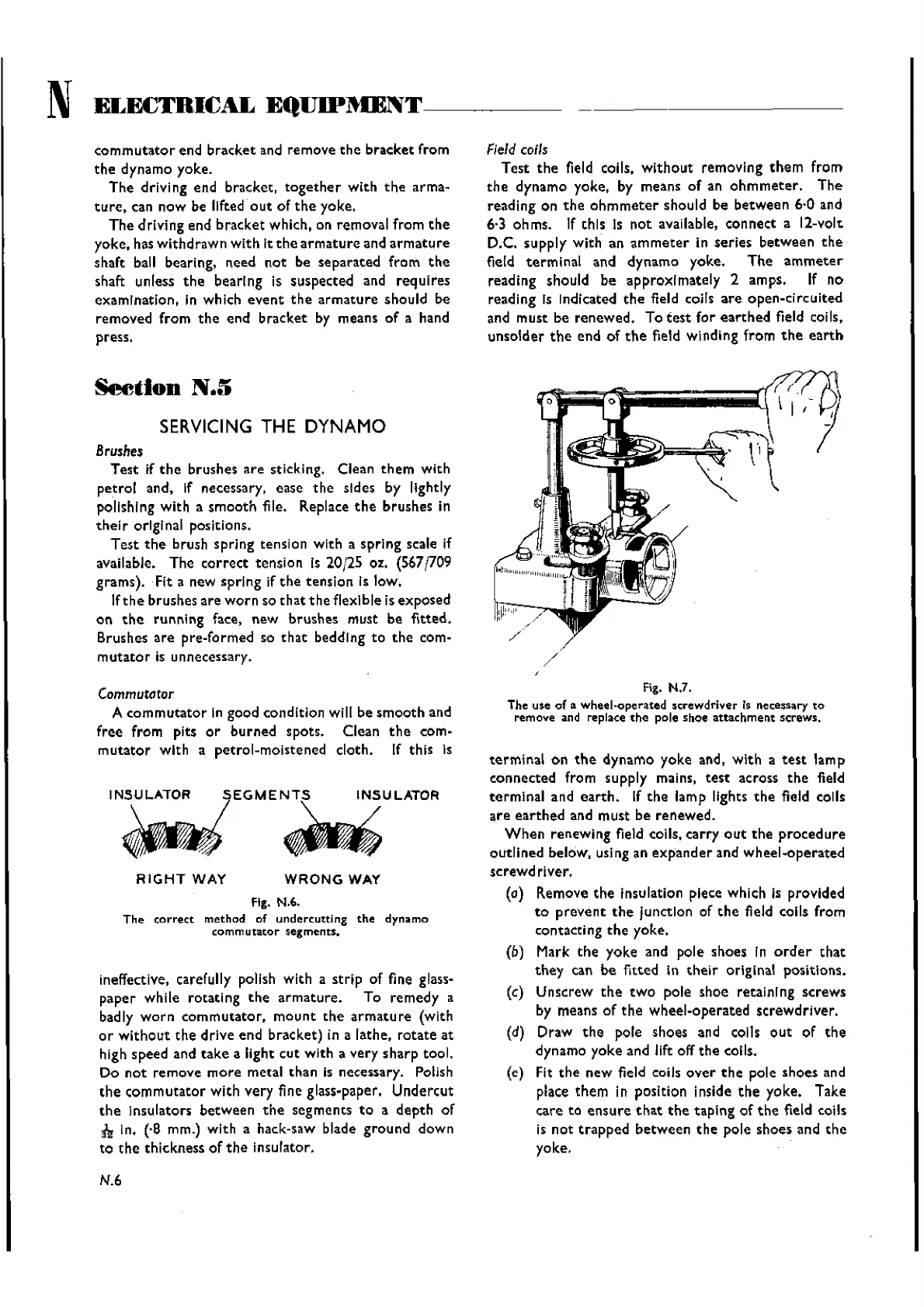

RIGHT

WAY

WRONG

WAY

fig. N.6.

The

correct

method of

undercutting

the

dynamo

commutator

segments.

ineffective. carefully polish with a

strip

of fine glass-

paper

while

rotating

the

armature.

To remedy a

badly

worn

commutator,

mount

the

armature

(with

or

without

the

drive end bracket) in a lathe,

rotate

at

high speed and

take

a light

cut

with a very sharp tool.

Do

not

remove

more

metal

than

is necessary. Polish

the

commutator

with very fine glass-paper.

Undercut

the

Insulators

between

the

segments

to

a

depth

of

n In. (·8 mm.) with a hack-saw blade

ground

down

to

the

thickness of

the

insulator.

N.6

Field

coils

Test

the

field coils.

without

removing

them

from

the

dynamo yoke, by means of an

ohmmeter.

The

reading on

the

ohmmeter

should be

between

6·0 and

6·3 ohms. If this Is

not

available, connect a 12-volt.

D.C. supply with an

ammeter

In series

between

the-

field

terminal

and dynamo yoke.

The

ammeter

reading should

be-

apprcxtrnaeely 2 amps. If no

reading Is Indicated

the

field coils

are

open-circuited

and must be renewed. To

test

for

earthed

field coils.

unsolder

the

end of

the

field winding from

the

earth

/

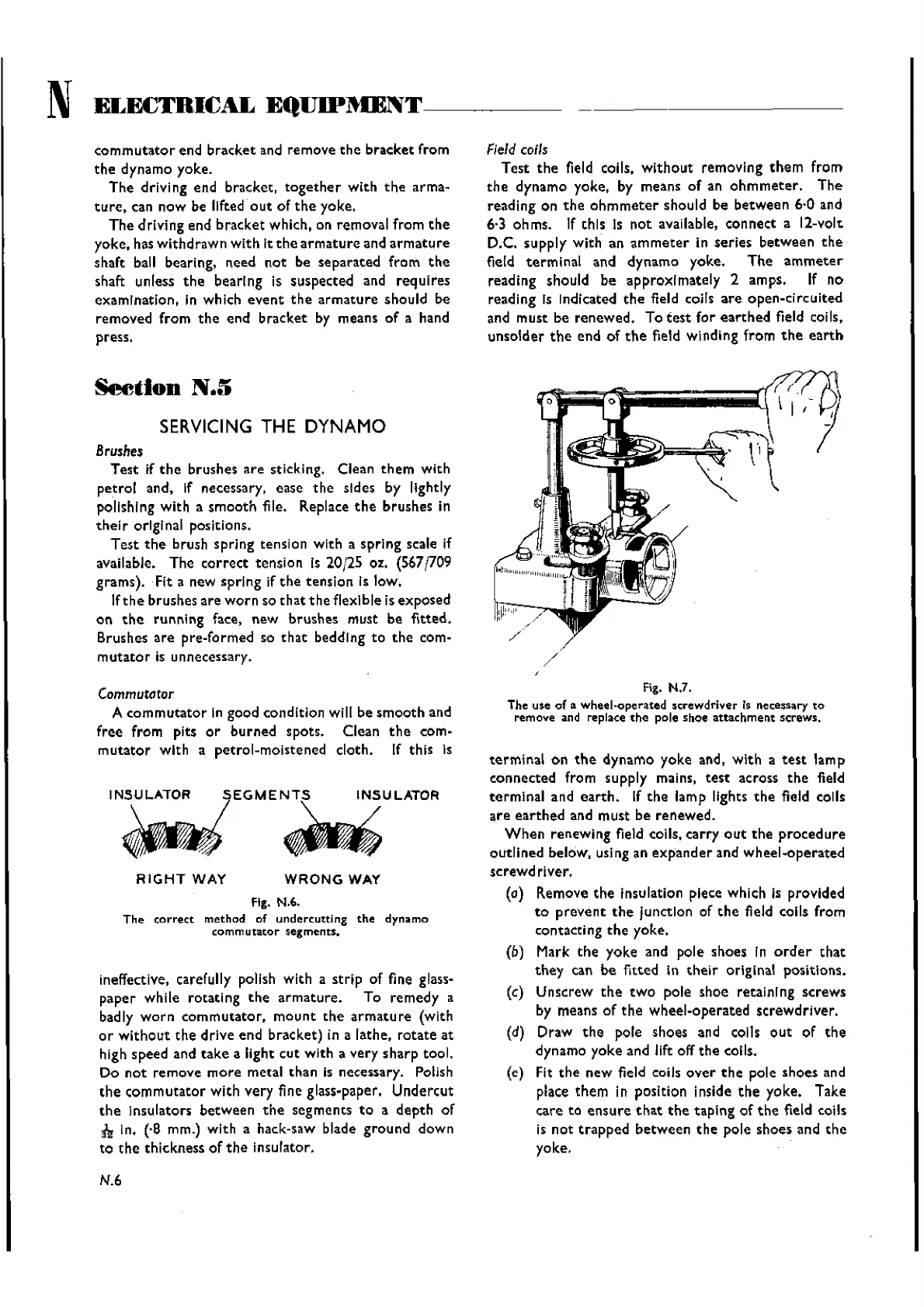

Fig. N.7.

The use of a

wheel-operated

screwdriver Is necessary

to

remove and replace

the

pole shoe

attachment

screws.

terminal

on

the

dynamo yoke and, with a

test

lamp

connected from supply mains,

test

across

the

field

terminal

and

earth.

If

the

lamp lights

the

field calls

are

earthed

and must be renewed.

When

renewing field coils.

carry

out

the

procedure

outlined below. using an

expander

and wheel-operated

screwdriver.

(0)

Remove

the

Insulation piece which Is provided

to

prevent

the

Junction of

the

field coils from

contacting

the

yoke.

(b) Mark

the

yoke and pole shoes ln

order

that

they

can be fitted in

their

original positIons.

(c) Unscrew

the

two

pole shoe retaining screws

by means of

the

wheel-operated screwdriver.

(d) Draw

the

pole shoes and coils

out

of

the

dynamo yoke and lift off

the

coils.

(e) Fit

the

new

field coils

over

the

pole shoes and

place

them

in position inside

the

yoke. Take

care to

ensure

that

the

taping

of

the

field coils

is

not

trapped

between

the

pole shoes and

the

yoke.

Wishvilles Classic

Automobile Library

Loading...

Loading...