FITTING

NEW

DISTRIBUTOR

BUSHES

Section

C.IO

CONDENSER

;1

0 l'ITACT

BRE:.AKER

~~.

PIVOT

Drive

out

the

parallel

driving

pin passing

through

the

collar

of

the

driving

gear

at

the

lower

end

of

the

spindle,

and

Withdraw

the

driVing

gear

from

the

spindle,

taking

care

of

the

washer

between

the

gear

and

the

spindle

wh ich

controls

the

end

float.

SCRE'NS

SECURING

CONTACT

PLATE

l

THE

IGNITION

EqUIP~IENT

C

<n

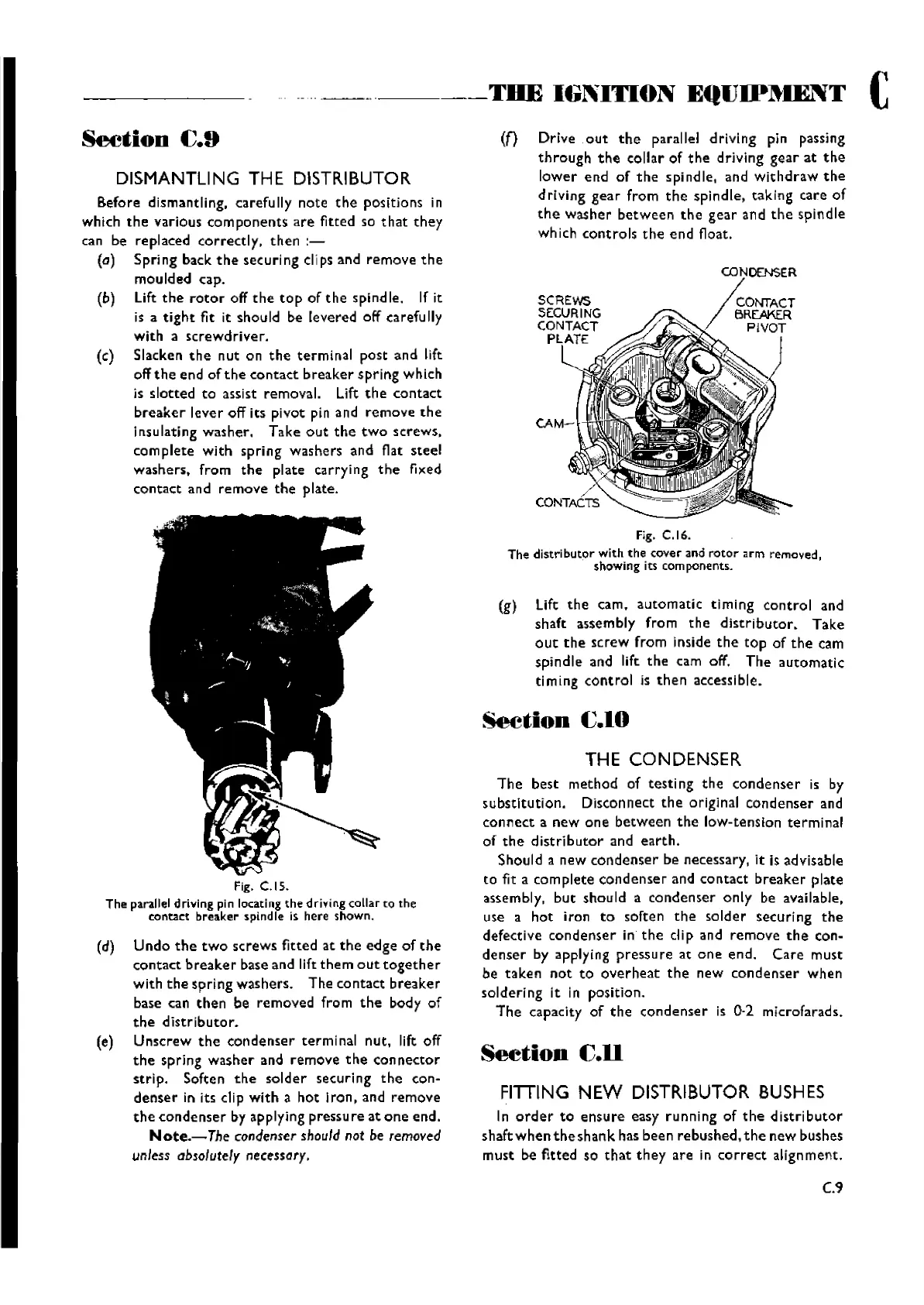

Fig. C.16.

The distributor with the cover and rotor arm removed,

showingits components.

(g)

lift

the

cam.

automatic

timing

control

and

shaft

assembly

from

the

distributor.

Take

out

the

screw

from

inside

the

top

of

the

cam

spindle

and lift.

the

cam off.

The

automatic

timing

control

is

then

accessible.

In

order

to

ensure

easy

running

of

the

distributor

shaftwhentheshank

has

been

rebushed,

the

new

bushes

must

be

fitted

so

that

they

are

in

correct

alignment.

THE CONDENSER

The

best

method

of

testing

the

condenser

is by

substitution.

Disconnect

the

original

condenser

and

connect

a

new

one

between

the

low-tension

terminal

of

the

distributor

and

earth.

Should

a

new

condenser

be necessary, it Is advisable

to

fit a

complete

condenser

and

contact

breaker

plate

assembly,

but

should

a

condenser

only

be available,

use a

hot

iron

to

soften

the

solder

securing

the

defective

condenser

in

the

dip

and

remove

the

con-

denser

by applying

pressure

at

one

end.

Care

must

be

taken

not

to

overheat

the

new

condenser

when

soldering

it in

position.

The

capacity

of

the

condenser

is

0·2

microfarads.

Seetion

C.ll

----_

..

-----

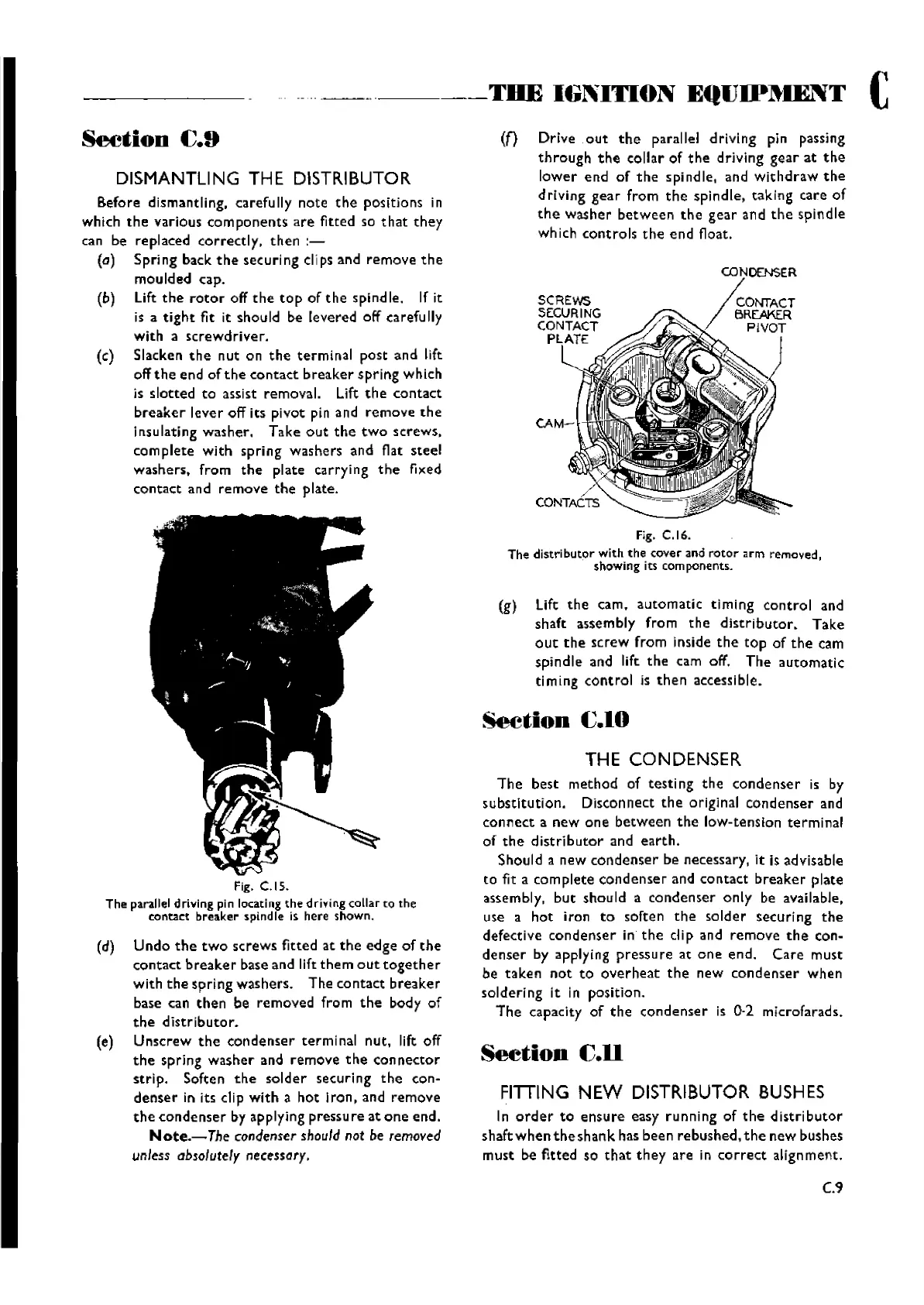

Fig.

C.IS.

The

parallel

drlvlng pin locating the drivingcollarto the

contact breaker spindIe is here shown.

(d)

Undo

the

two

screws

fitted

at

the

edge

of

the

contact

breaker

base and lift

them

out

together

with

the

spring

washers.

The

contact

breaker

base can

then

be

removed

from

the

body

of

the

distributor.

(e)

Unscrew

the

condenser

terminal

nut.

lift off

the

spring

washer

and

remove

the

connector

strip.

Soften

the

solder

securing

the

con-

denser

in its clip

with

a

hot

Iron,

and

remove

the

condenser

by applying pressu

re

at

one

end.

Note.-The

condenser

should

not be removed

unless absolutely necessary.

DISMANTLING THE DISTRIBUTOR

aefore

dismantling, carefully

note

the

positions

in

which

the

various

com

portents

are

fitted so

that

they

can be

replaced

correctly.

then

:-

(a) Sprj ng back t he sec uri ng cIi

ps

and

remove

th

e

moulded

cap.

(b) Lift

the

rotor

off

the

top

of

the

spind

Ie. If it

is

a

tight

fit it

shou

Id be

levered

off carefu lIy

with

a

screwdriver.

(c) Slacken

the

nut

on

the

terminal

post

and

lift

off

the

end

of

the

contact

breaker

spring

which

is

slotted

to

assist

removal.

Lift

the

contact

breaker

lever

off

its

pivot

pin and

remove

the

insulating

washer.

Take

out

the

two

screws.

complete

with

spring

washers

and

flat

steel

washers.

from

the

plate

carrying

the

fixed

contact

and

remove

the

plate.

Seetion

fj.9

C.9

Wishvilles Classic

Automobile Library

Loading...

Loading...