SeedOD

.&.38

THE

ENGINE

MOUNTING

AND

CONTROL LINK

The

power

unit

is flexibly

mounted

to

the

chassis

frame

on

a ru

bber

block

at

the

front

and on

two

ru

bber

blocks

underneath

the

gearbox

at

the

rear.

As

the

location

of

these

rubber

mountings

would

permit

a

large

rockJng

movement

of

the

power

unit

under

certain

circumstances, a

control

link Is fitted

at

the

forward

end

to

control

the

torque

reaction effects on

the

power

unit.

The

rear

mounting

consists

of

two

loose

rubber

blocks on which

the

engine

rests

and which

are

TIIti

ENGINE A

the

adjuster

in

the

appropriate

direction,

allowing

the

assembly

to

be removed

complete

with

Inner

rubbers

and cups by rocking

the

engine.

Refitting

the

control

link

Screw

the

adjuster

locknuts

right

home

on

the

threads

of

the

two

adjusting

rods

and

screw

the

rods

into

the

adjuster

barrel as far as

they

will go. Place

the

two

Inner

cups and

rubbers

on

the

ends

of

the

adjusting rods. I

nsert

one

end

of

the

assem bly th rough

the

bracket

on

the

engine and. holding it

with

Its

rubber

tight

against

the

bracket,

rock

the

engine

towards

the

left of

the

car

on its

rubber

mounting

to

enable

the

other

end of

the

adjusting rod assembly

to

be

entered

into

the

frame bracket.

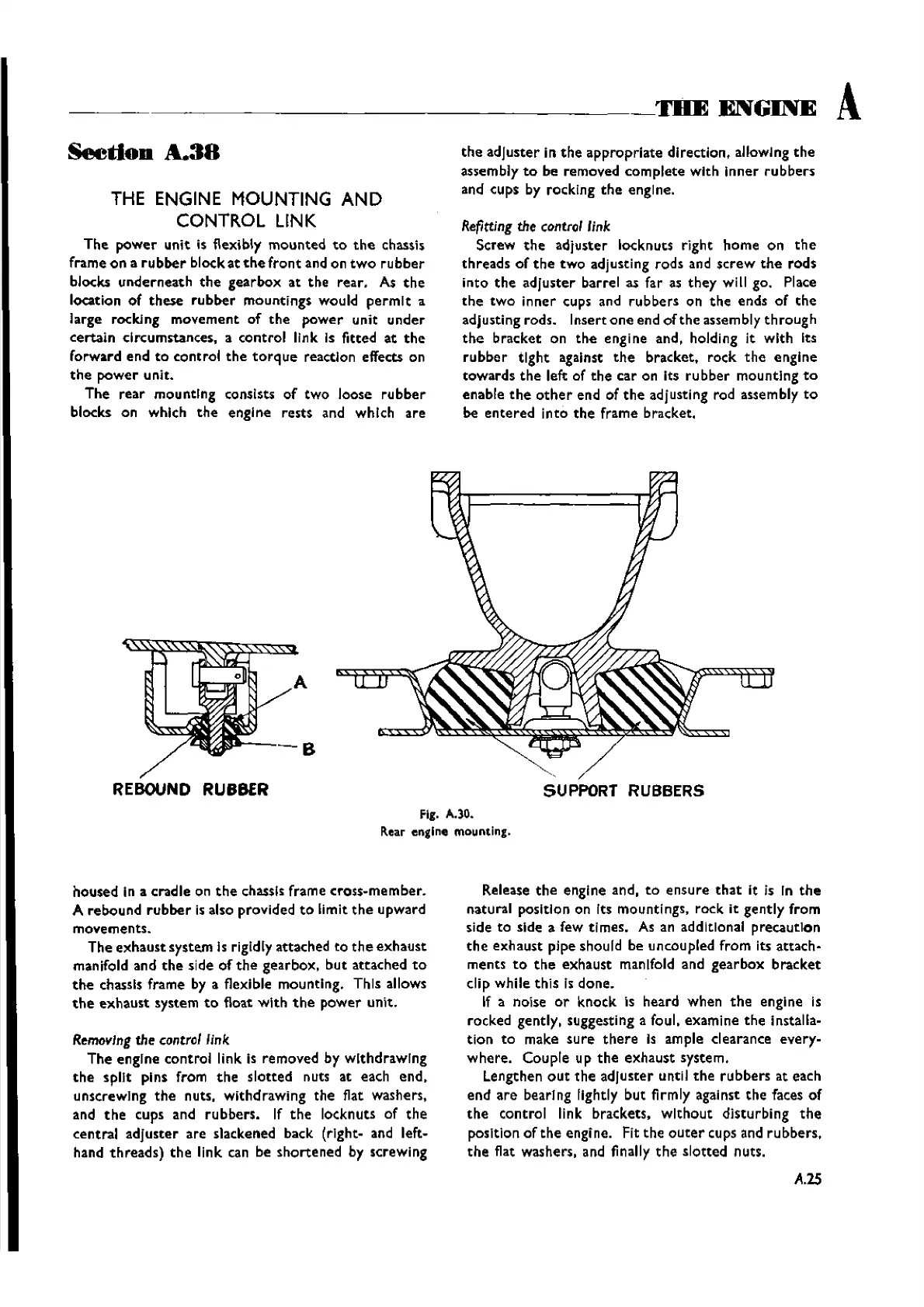

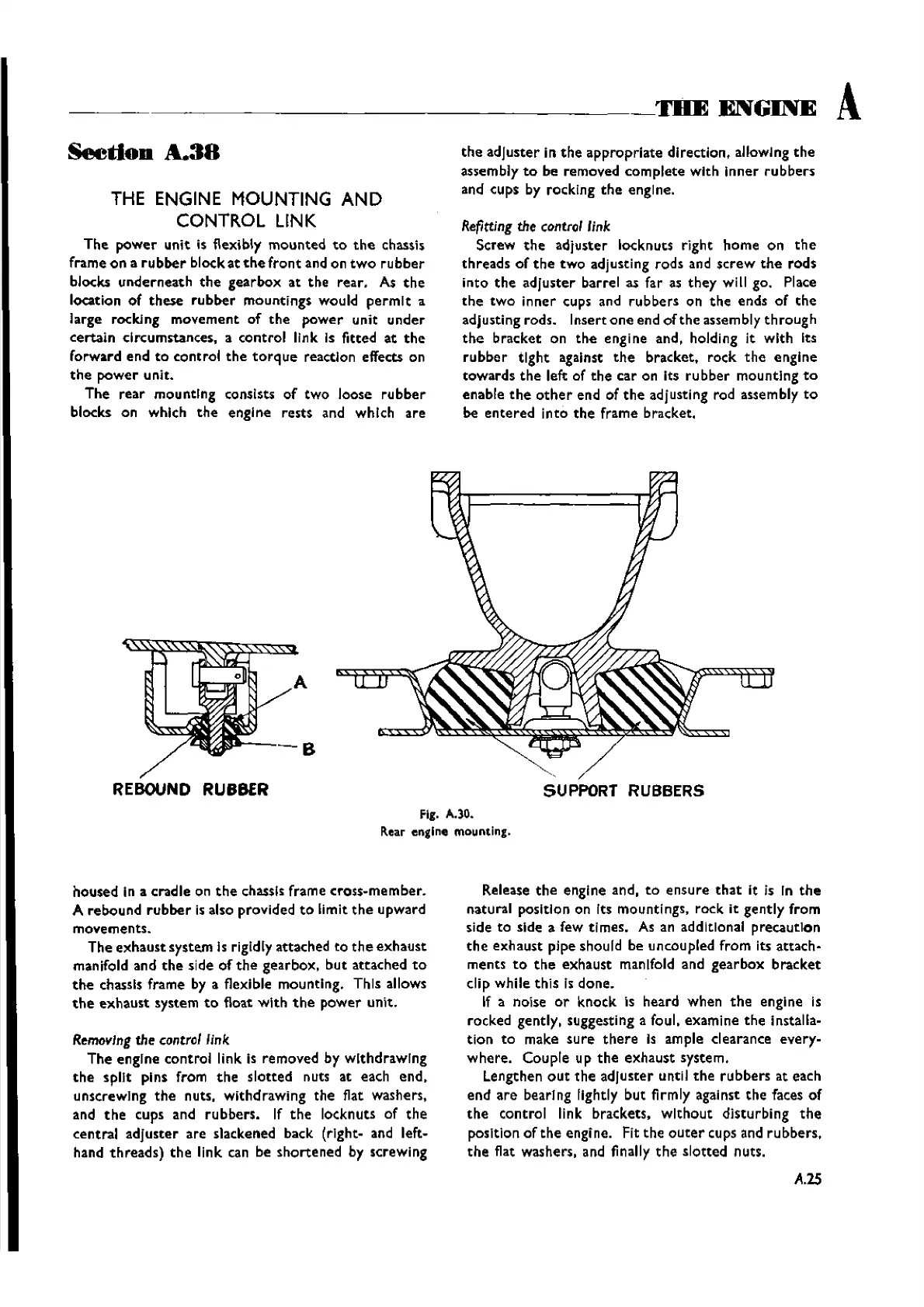

REBOUND RUBBER

SUPPORT RUBBERS

Fig. A.30.

Rear engine mounting.

housed

in a

cradle

on

the

chassis frame

cross-member.

A

rebound

rubber

is also provided

to

limit

the

upward

movements.

The

exhaust

system Is rigidly attached to

the

exhaust

manifold and

the

side

of

the

gearbox,

but

attached

to

the

chassis frame by a flexible mounting. This allows

the

exhaust

system

to

float

with

the

power

unit.

Removing

the

control

link

The

engine

control

link is

removed

by WithdrawIng

the

spilt

pins from

the

slotted

nuts at each

end,

unscrewing

the

nuts,

withdrawing

the

flat washers,

and

the

cups and

rubbers.

If

the

locknuts of

the

central

adjuster

are

slackened back (rlght- and left-

hand

threads)

the

link can be

shortened

by screwing

Release

the

engine and,

to

ensure

that

It Is In

the

natural position on Its mountings,

rock

it

gently

from

side to side a few ttrnes, As an additional

precaution

the

exhaust

pipe should be uncoupled

from

its

attach-

ments

to

the

exhaust

manifold and

gearbox

bracket

clip

while

this

Is

done.

If a noise

or

knock

is

heard

when

the

engine is

rocked gently, suggesting a foul,

examine

the

Installa-

tion

to

make

sure

there

Is ample clearance

every-

where.

Couple

up

the

exhaust

system.

Lengthen

out

the

adjuster

until

the

rubbers

at each

end

are

bearing lightly

but

firmly against

the

faces

of

the

control

link

brackets.

without

disturbing

the

position

of

the

engine. Fit

the

outer

cups and

rubbers,

the

flat washers, and finally

the

slotted

nuts.

A.25

Wishvilles Classic

Automobile Library

Loading...

Loading...