--

--

.-

--

TIIE

ENGINE A

maintaining engine lubrication untila

new

filter Isfitted.

The spring for this ball valve should be

19

gauge

or

·040 in. (1·02 mm.), ·5354 In. (13,59 mrn.) overall

diameter.

2·224 In. (56·5 mm.) free length. Total

numberof

coils 12,glving a load

of5

lb. (2,27kilograms)

wilen

compressed

to

a length of ·649 In. (16·5 mrn.].

SeetiOD

A.7

REMOVAL

AND

REPLACEMENT

OF

THE MAIN

AND

BIG-END

BEARINGS

The replacement of big-end bearings can be carried

out

after

removal of

the

sump.

without

taking

the

engine from

the

frame,

but

in

order

to

replace

the

main bearings

the

engine must be removed. Renew-

able steel-backed bearings

are

used

for

both

the

main crankshaft

bear

ings and

the

big-end bearings.

It is Imperative

that

no adjustments be made

to

the bearings.

Bearings

which

are

worn should be

~

. .

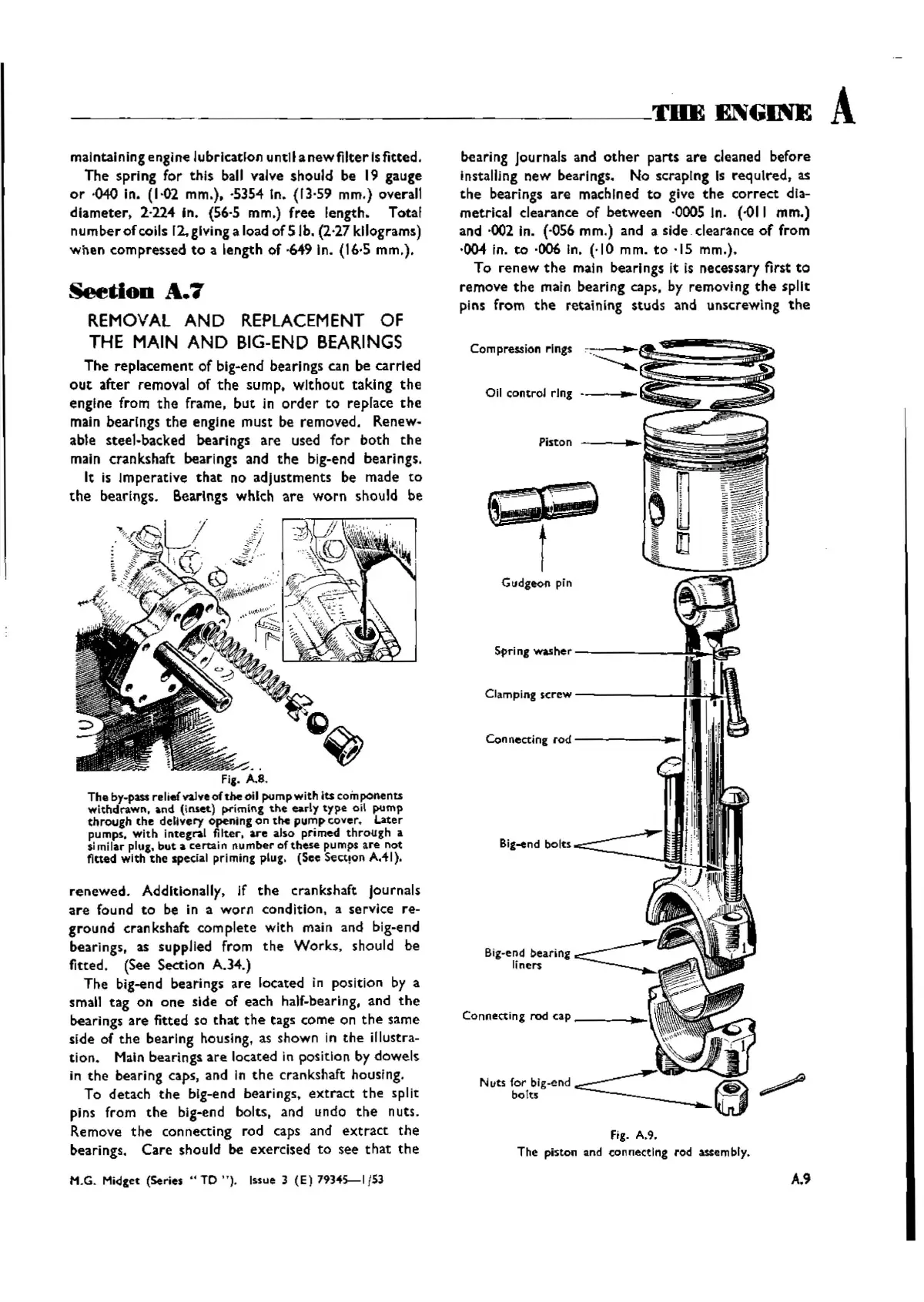

Fig. A.S.

The

by.pus

reliefvalve of the

011

pump with Its components

withdrawn.

lnd

(inset)

pr

iming

the

t3.rly

type

oil

pump

through

the

delivery opening on

the

pu~p

cover

.

later

pumps,

with

integral filter.

are

also primed

through

a

s

lmilar

plug.

but

a

certa

in number of

these

pumps are not

fitted with

the

spe'ial

priming plug. (See

Secqon

A.-4-I).

renewed.

Additionally, If

the

crankshaft Journals

are

found

to

be in a

worn

condition, a service re-

ground

crankshaft

complete

with main and big-end

bearings,

as

supp

lied from

the

Works

. should be

fitted. (See Section

A.H.)

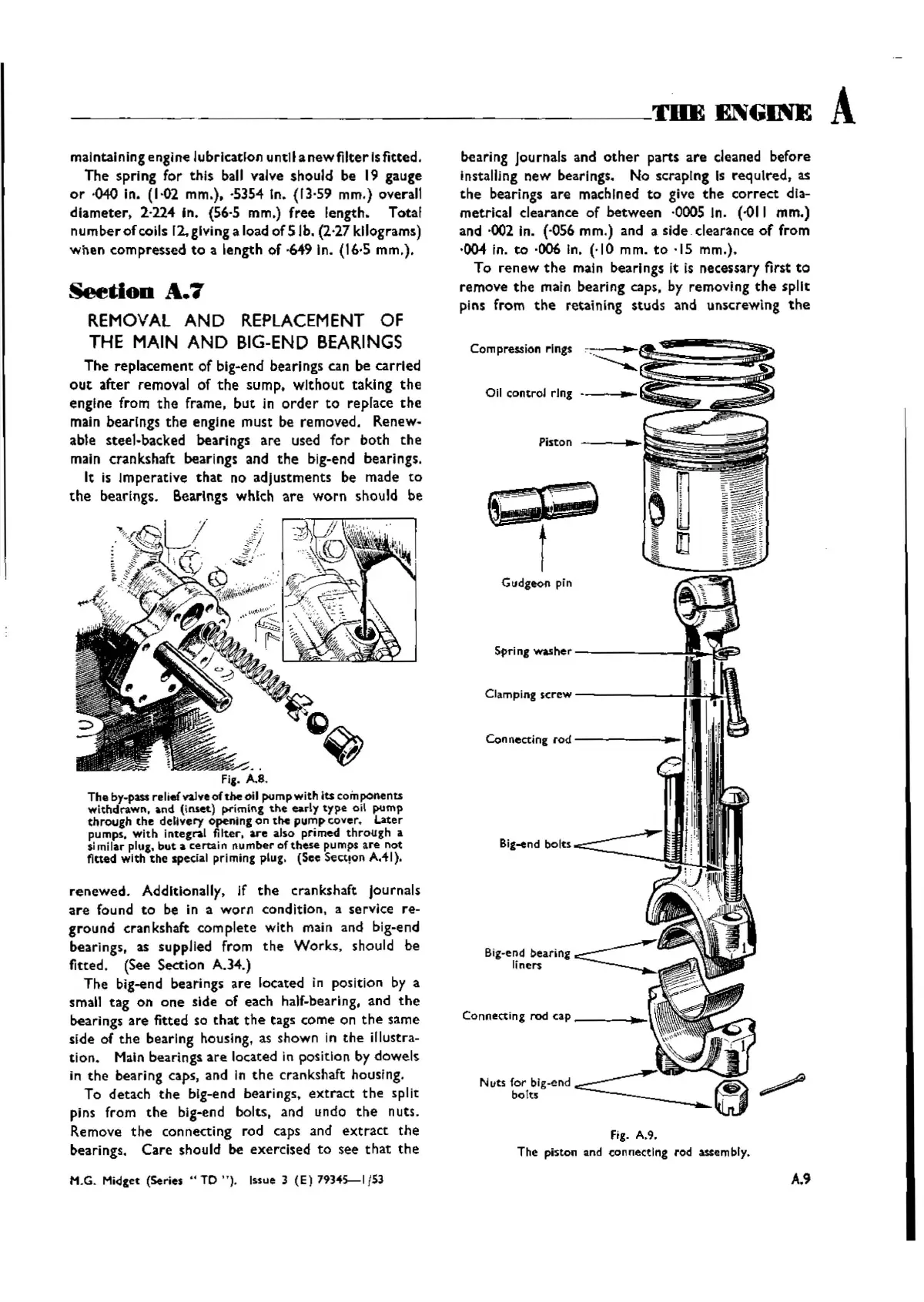

The big-end bearings are located in position by a

small

tag on

one

side of each half-bearing, and

the

bearings

are

fitted so

that

the

tags come on

the

same

side of

the

bearing housing. as shown in

the

illustra-

t ion. Main bearings

are

located in position by

dowe

ls

in

the

bearing caps, and In

the

crankshaft housing.

To detach

the

big-end bearings,

extract

the

split

pins from

the

big-end bolts, and undo

the

nuts.

Remove

the

connecting rod caps and

extract

the

bearings.

Care

should be exercised

to

see

that

the

M.G. Midget (Series .. TO •'J. Issue 3 (E) 793045-1 /53

bearing Journals and

other

parts

are

cleaned before

Installing new bearings. No scraping Is

required,

as

the

bearings

are

machined

to

give

the

correct

dia-

metrical clearance of

between

·0005 In.

(·011

mm.)

and

·002

In. (,056 mm.) and a side clearance

of

from

,004 in.

to

·006 In. (·10 mm.

to

·15 mrn.),

To

renew

the

main bearings it is necessary first

to

remove

the

main bearing caps, by removing

the

split

pins from

the

retaining studs and unscrewing

the

Compression rings ...

~

~~

-;;~~=:::::::::::ii~

.

."""

Oil control rJng

..

Piston

..

Gudgeon pin

Spring

WlSher

-----_-!'!.~~

Clamping screw

-------!Jl~~ni

Connecting rod

-----

....

-1

Big-end bolts

Connecting

rod

cap

....

_1

Fig. A.9.

The piston and connecting rod

assembly.

A.9

Wishvilles Classic

Automobile Library

Loading...

Loading...