B

TIlE

BEAR

AXLE

--------.--

to

the

bearings. This can be checked by applying

the

special

tool,

Part

No.

68839. (See Section

Q.)

R.otate

the

spindle

eight

or

ten

times

to

seat

the

bearings.

Fit

the

checking

fixture

(Part

No. 68829) in

the

axle

cover

0p'ening and make

sure

that

the

locating

arm

makes firm

contact

with

the

side of

the

dummy

spindle

head. (See Fig. H.IS.)

This leaves a

gap

between

the

dummy

pinion head

and

the

checking anvil of

the

fixture, and

this

is

the

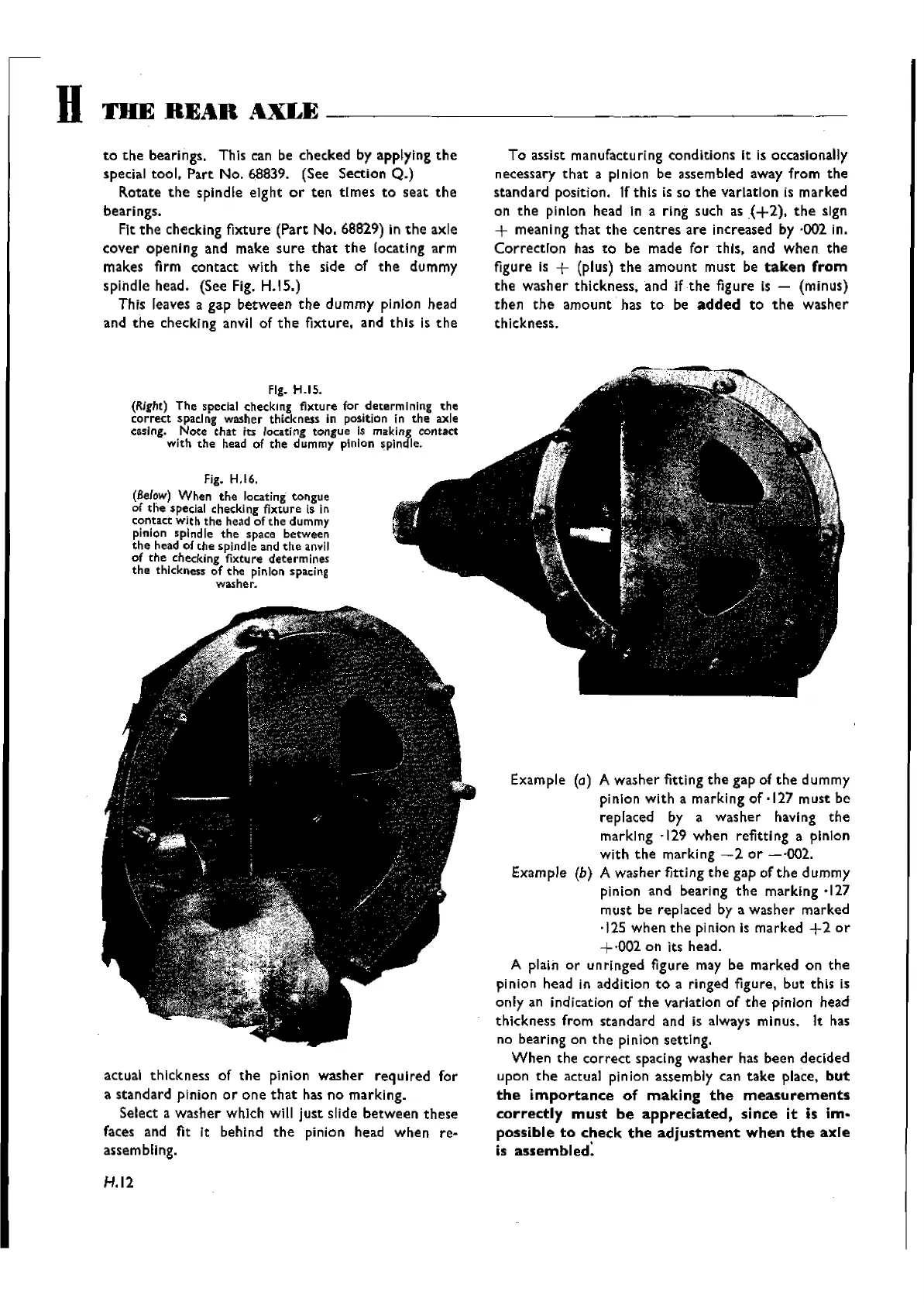

Fig. H.15.

(Right) The special checkmg fixture for determining

the

correct

spacing washer thickness in position in

the

axle

casing.

Note

that

fts locating tongue Is making oontaet

with

the

head of

the

dummy pInion spindle.

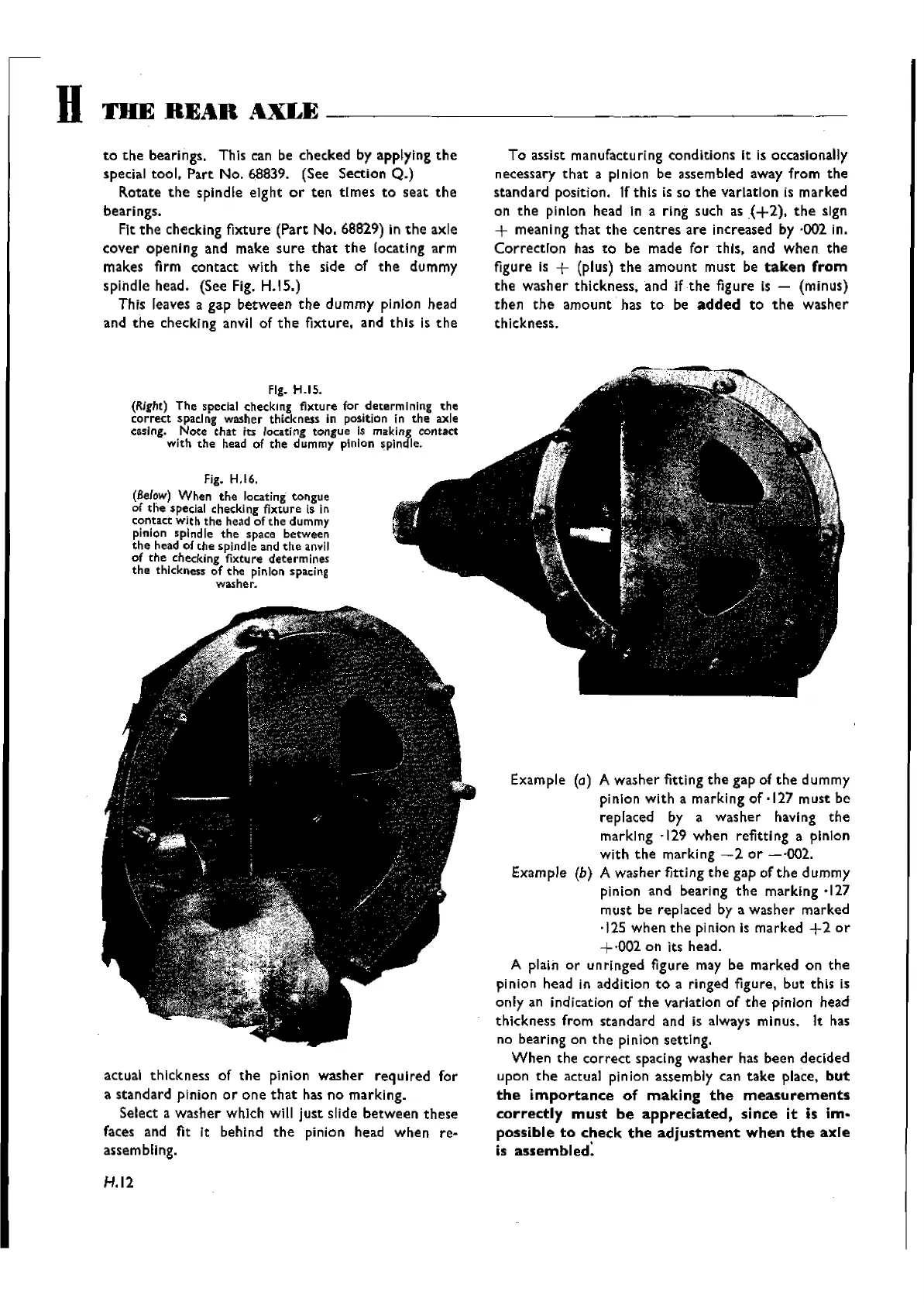

Fig. H.16.

(Below)

When

the

locating tongue

of

the

special checki ng fixture is ill

contact

with

the

head of

the

dummy

pinion spindle

the

space between

the

head of the splnd Ie and

the

anviI

of

the

checking flxture determines

the

thic:kness of

the

pinion spacing

washer.

actual thickness of

the

pinion

washer

required

for

a

standard

pinion

or

one

that

has no

marking.

Select a

washer

which will

just

slide

between

these

faces and fit It behind

the

pinion head

when

re-

assembling.

H.12

To assist manufacturing

conditions

it is occasionally

necessary

that

a pinion be assembled away

from

the

standard

position. If

this

is so

the

variation

is

marked

on

the

pinion head In a ring such as .(+2),

the

sign

+ meaning

that

the

centres

are

increased by ·002 in.

Correction

has

to

be made for thts, and

when

the

figure is + (plus)

the

amount

must be

taken

from

the

washer

thickness, and if

the

figure Is - (minus)

then

the

amount

has

to

be

added

to

the

washer

thickness.

Example (a) A

washer

fitting

the

gap of

the

dummy

pinlon

with

a marklng

of

·127

must

be

replaced

by a

washer

having

the

marklng ·129

when

reflttl ng a pinIon

with

the

marking

-2

or

-·002.

Example (b) A

washer

fitting

the

gap of

the

dummy

pinion

and

bearing

the

marking

·127

must

be replaced by a

washer

marked

·125

when

the

pinion is

marked

+2

or

+·002

on its head.

A plain

or

unringed

figure may be

marked

on

the

pinion head in addition

to

a ringed figure,

but

this

is

only

an indication

of

the

variation

of

the

pinion

head

thickness

from

standard

and is always minus. It has

no bearing on

the

pinion

setting.

When

the

correct

spacing

washer

has

been

decided

upon

the

actual pinion assembly can

take

place,

but

the

importance

of

making

the

measurements

correctly

must

be

appreciated,

since

it

is

lm-

possible

to

check

the

adjustment

when

the

axle

is

assembled:

Wishvilles Classic

Automobile Library

Loading...

Loading...