N ELECTRICAL

EQUIPMENT-------------

worn so

that

they

no longer bear on

the

commutator

or

if

the

brush flexible has become exposed on

the

running face they must be renewed.

If

the

commutator

is blackened

or

dirty. clean it by

holding a petrol-moistened

doth

against it while

the

armature

Is

rotated.

Dismantling

Take off

the

cover band

"A"

(Fig.

N.II)

at

the

commutator

end. hold back

the

brush

springs"

D "

and

take

out

the

brushes"

B " from

their

holders.

Withdraw

the

two

through

bolts and remove

the

armature

complete with driving end bracket.

Remove

the

terminal nuts and washers from

the

terminal post at

the

commutator

end bracket and

remove

the

commutator

end bracket.

Brushes

(0)

Test

the

brush springs with a spring scale.

The

correct

tension is 30-40 oz.

(850--1134

grams). Fit a new spring If

the

tension Is low.

(b) If

the

brushes are

worn

so

that

they

no longer

bear on

the

commutator,

or

If

the

flexible

connector

has become exposed. on

the

running

face,

they

must be renewed.

Two

of

the

brushes are connected

to

termInal eyelets

"A

It

(Fig. N.12) attached to

the

brush boxes

"

B"

on

the

commutator

end bracket. and

two

"A"

(Fig. N.13)

are

connected

to

a

tappi ng .. B " on

the

field coiIs.

The flexible connectors

must

be removed by un-

soldering and

the

connectors of

the

new brushes

secured In

their

place by soldering. The brushes are

pre-formed so

that

bedding of

theIr

working face

to

the

commutator

is unnecessary.

Drive

(0) If

the

pinion is

tight

on

the

screwed sleeve,

wash away any

dlrt

with paraffin (kerosene).

(b) If any parts

are

worn

or

damaged

they

must be

renewed.

(c) Remove

the

split

pin"

H " (Fig. N.14) from

the

shaft

nut

at

the

end

of

the

starter

drive.

Hold

the

squared end of

the

starter

shaft at

the

commutator

end by means of a

spanser

and unscrew

the

shaft

nut"

J."

(d)

Lift

off

the

main spring .. K .. (Fig. N.14) and

remove

the

retaining

ring"

L."

(e) The control

nut

..

M,"

sleeve

"N"

and

restraining

spring"

P"

will now slide off.

(n

Withdraw

the

spllned

washer

from

the

armature

shaft and remove

the

pinion and

barrel assembly.

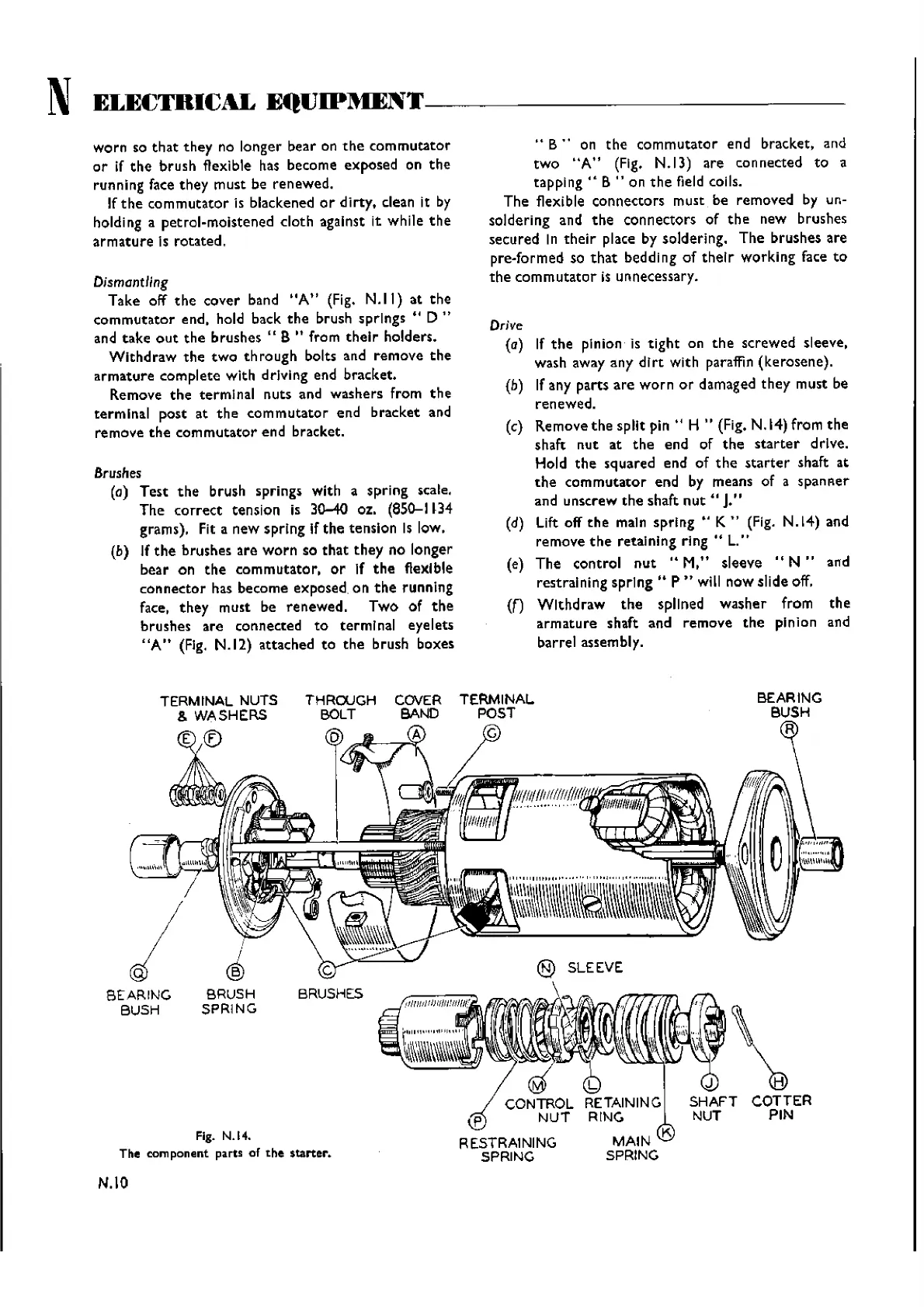

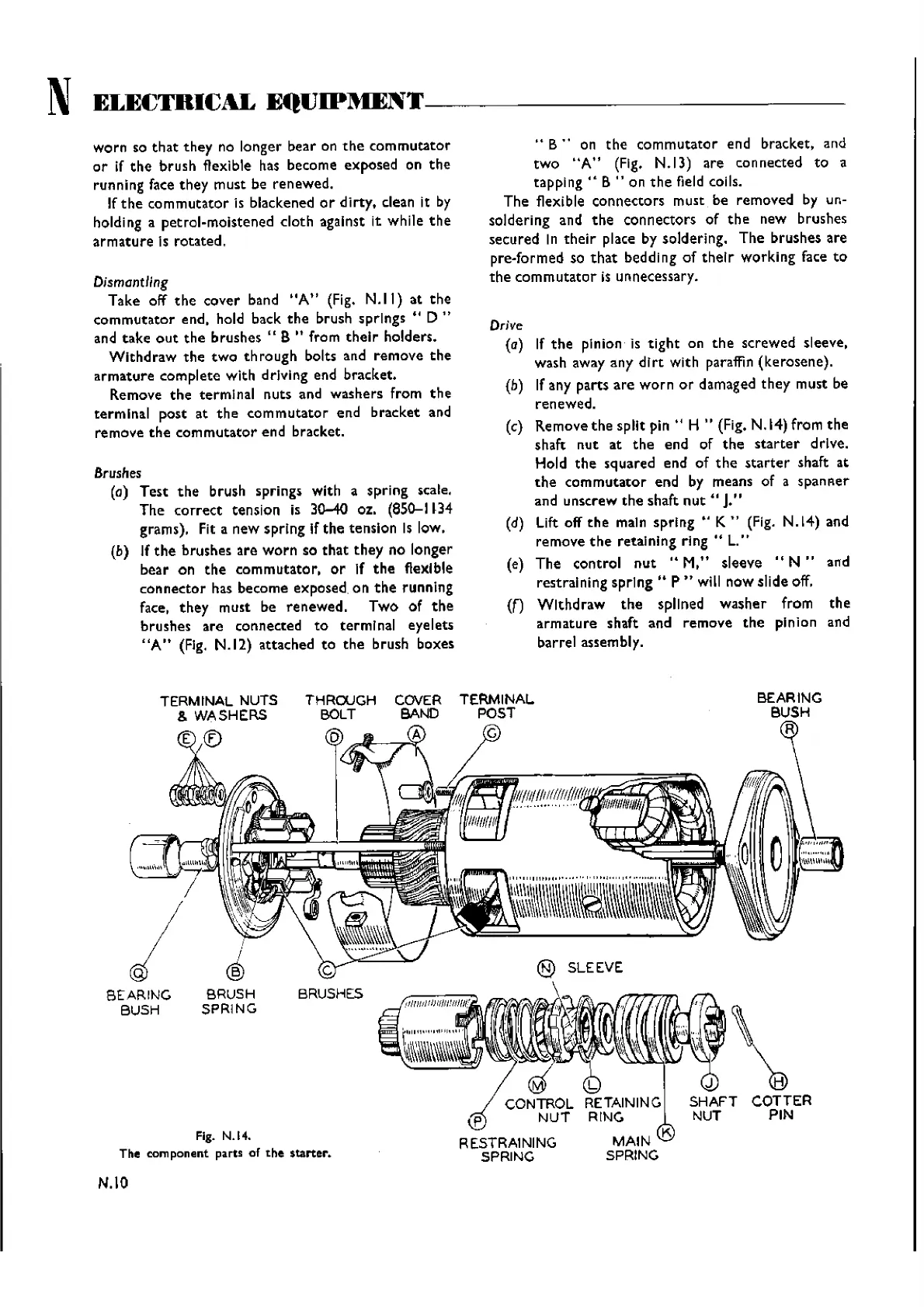

Fig. N.H.

The

component

parts of

the

$tarter.

BEARING

BUSH

R

COTTER

PIN

@ SLEEVE

\

COVER

TERMINAL

BAND POST

A G

...,.jlLL--..---....>;r'"

THROUGH

BOLT

D

C

BRUSHES

i

I

®

BRUSH

SPRING

TERMINAL NUTS

& WASHERS

E ®

BEARING

BUSH

N.IO

Wishvilles Classic

Automobile Library

Loading...

Loading...