S CHASSIS FRAME

REPAIBS--~~

that

It is a very difficult

operation

to

re-form It exactly

to

Its original shape.

Note.-We

do not

recommend

that this

operation

becarriedout bythe DistrIbutoror Dealer

unless

adequate

assembly

fixtures

are available.

The

majority of frames

are

damaged as a

result

of

oblique

frontal impacts, and straightening of

the

front

and'section of

the

frame is carried

out

as follows. (See

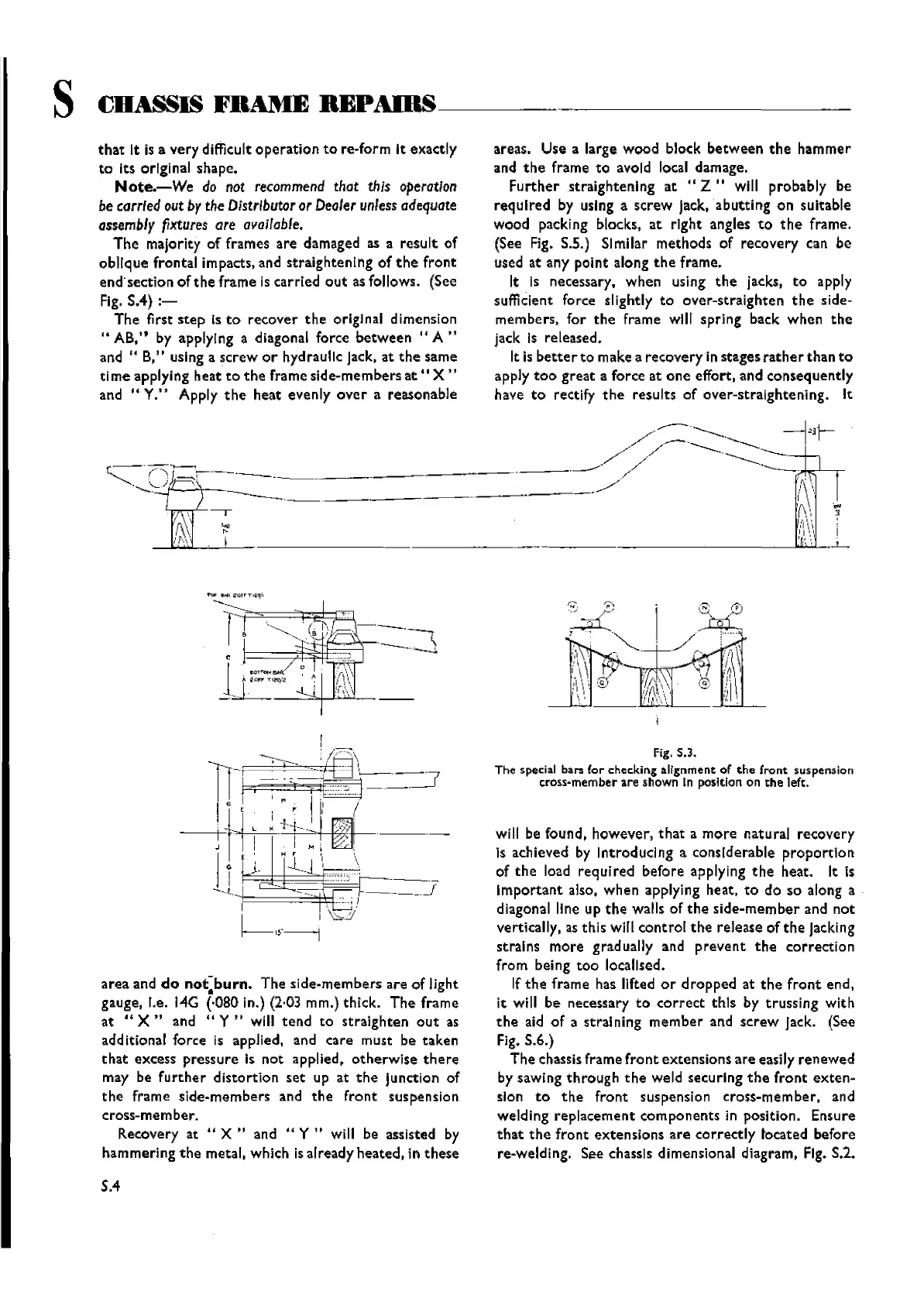

Fig.

5.4):-

The

first

step

Is

to

recover

the

origInal dimension

.. AB," by applying a diagonal force

between"

A "

and"

B,"

using a

screw

or

hydraulic Jack, at

the

same

time

applying heat

to

the

frame side-members

at"

X"

and

"Y."

Apply

the

heat

evenly

over

a reasonable

area

and

do

not:burn. The

side-members

are

of light

gauge, I.e. 14G (·080 in.) (2·03 mm.) thick.

The

frame

at ..

X"

and

"Y"

will

tend

to

straighten

out

as

additional force is applied, and

care

must be taken

that

excess

pressure

is

not

applied.

otherwise

there

may be

further

distortion

set

up at

the

Junction of

the

frame

side-members

and

the

front

suspension

cross-member.

Recovery at

"X

" and

"Y"

will be assisted by

hammering

the

metal, which isalready

heated,

in

these

SA

areas. Use a large

wood

block

between

the

hammer

and

the

frame

to

avoid local damage.

Further

straightening at

"Z

II

will probably be

requlred by using a

screw

jack.

abutting

on suitable

wood

packing blocks. at right angles

to

the

frame.

(See Fig. 5.5.) Similar methods of recovery can be

used at any

point

along

the

frame.

It Is necessary.

when

using

the

jacks,

to

apply

sufficient force

slightly

to

over-straighten

the

side-

members, for

the

frame will spring back

when

the

jack is released.

It is

bette

r

to

make a recovery In stages

rathe

r

than

to

apply

too

great

a force at

one

effort, and consequently

have

to

rectify

the

results of

over-straightening.

It

I

_________

~

------''''''-'-L-....L-

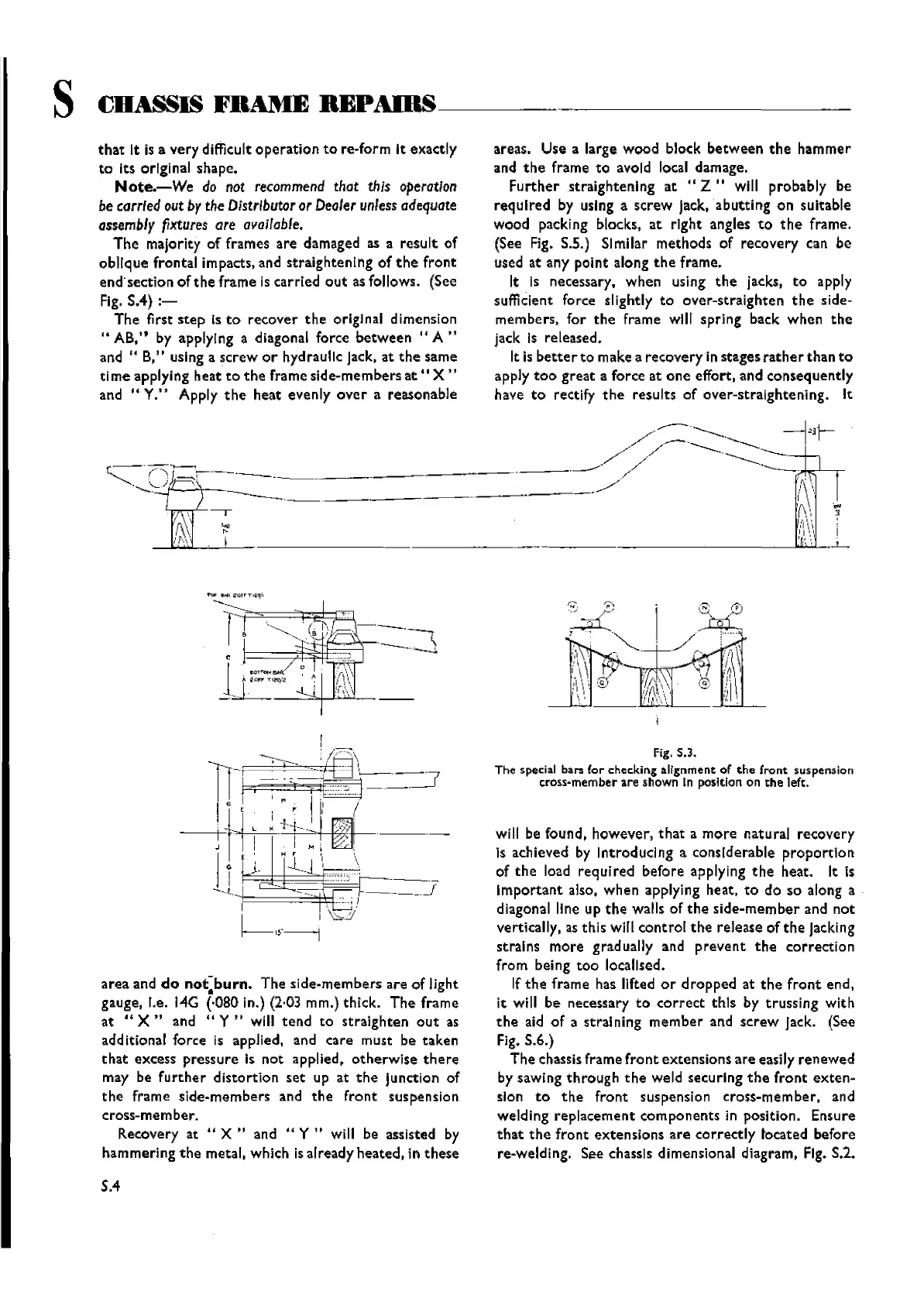

fig. S.3.

The special bars

for

checking

alignment

of

the

front

suspension

cress-member are

shown

In

position

on the left.

will be found,

however,

that

a

more

natural

recovery

is achieved by Introducing a considerable

proportion

of

the

load

required

before applying

the

heat. It Is

Important

also.

when

applying heat.

to

do so along a

diagonal line up

the

walls of

the

side-member

and

not

vertically, as

this

will

control

the

release of

the

Jacking

strains

more

gradually and

prevent

the

correction

from

being

too

localised.

If

the

frame has lifted

or

dropped

at

the

front

end,

it will be necessary

to

correct

this

by

trussing

with

the

aid of a straining

member

and

screw

Jack. (See

Fig. S.6.)

The

chassis frame

front

extensions

are

easily

renewed

by sawing

through

the

weld securing

the

front

exten-

slon

to

the

front

suspension

cross-member,

and

welding

replacement

components

in position. Ensure

that

the

front

extensions

are

correctly

tocated before

re-welding. See chassis dimensional diagram, Fig. 5.2.

Wishvilles Classic

Automobile Library

Loading...

Loading...