B

TIlE

FUEL

SYSTEM----------------

you should be able

to

blow freely

but

not

be able

to

suck air back, and with

the

latter

you should be able

to

suck freely and

not

blow

air

back. If

these

are

In

order

it Is best

to

leave

the

valves alone,

Clean

the

filter in fuel with a brush and swill

out

the

body of

the

pump.

Next

unscrew

the

diaphragm assembly from Its

trunnion

in

the

contact

breaker.

This is

done

by

rotating

the

whole assembly in an anti-clockwise

direction.

While

doing this, care should be

taken

not

to

lose

the

brass rollers fitted behind

the

dia-

phragm. The easiest method Is to hold

the

body in

the

left hand and

to

rotate

the

diaphragm.

Now

remove

the

contact

breaker

cover

by taking

off

the

nut

which holds it In place on

the

terminal,

and

then

undo

the

farther

nut

on

the

terminal. which acts

as a seating

for

the

cover. Beneath this will be found

a lead

washer

which is squeezed

into

the

thread

on

the

terminal. This should be

cut

away

with

a pocket

knife, allowing

the

terminal

to

be pushed down a

short

way so

that

the

tag on

the

coli end is free on

the

terminal.

The

5 B.A. screw holding

the

contact

blade in

position should now be removed,

together

with Its

spring

washer

and

the

contact

blade.

The

two

long 2 B.A. screws holding

the

bakelite

pedestal In place should now

be removed,

together

with

their

spring washers. This will enable

the

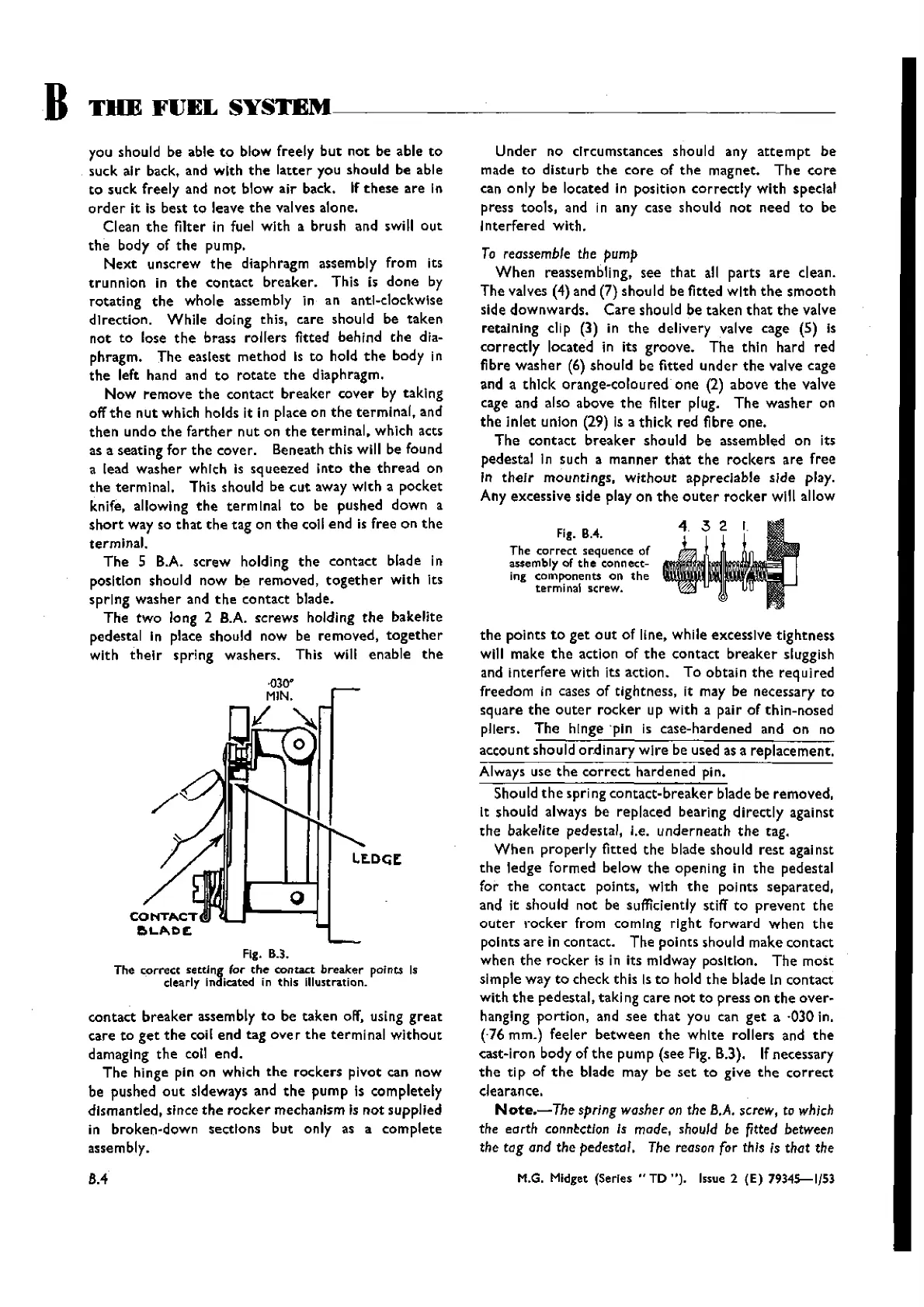

Fig. 8.3.

The

correct

setting for

the

contact

breaker

points Is

clearly

Indicated in

this

Illustration.

contact

breaker

assembly

to

be taken off, using

great

care

to

get

the

coil end tag

over

the

terminal

without

damaging

the

coli end.

The

hinge pin on which

the

rockers pivot can now

be pushed

out

sideways and

the

pump Is completely

dismantled, since

the

rocker

mechanism Is not supplied

in broken-down sections but only as a

complete

assembly.

8,4

Under

no circumstances should any

attempt

be

made

to

disturb

the

core

of

the

magnet.

The

core

can only be located in position

correctly

with special

press tools, and in any case should

not

need

to

be

Interfered with.

To

reassemble the pump

When

reassembling, see

that

all parts

are

clean.

The valves

(4) and (7) should be fitted with

the

smooth

side downwards.

Care

should be

taken

that

the

valve

retaining elip

(3) in

the

delivery valve cage (5) Is

correctly

located in its groove. The thin hard red

fibre

washer

(6)should be fitted

under

the

valve cage

and

a

thick

orange-coloured

one

(2) above

the

valve

cage and also above

the

filter plug.

The

washer

on

the

inlet

union (29) Is a

thick

red fibre one.

The

contact

breaker

should be assembled on its

pedestal In such a manner

that

the

rockers

are

free

In

their

mountings,

without

appreciable sIde play.

Any excessive side play on

the

outer

rocker

wlll allow

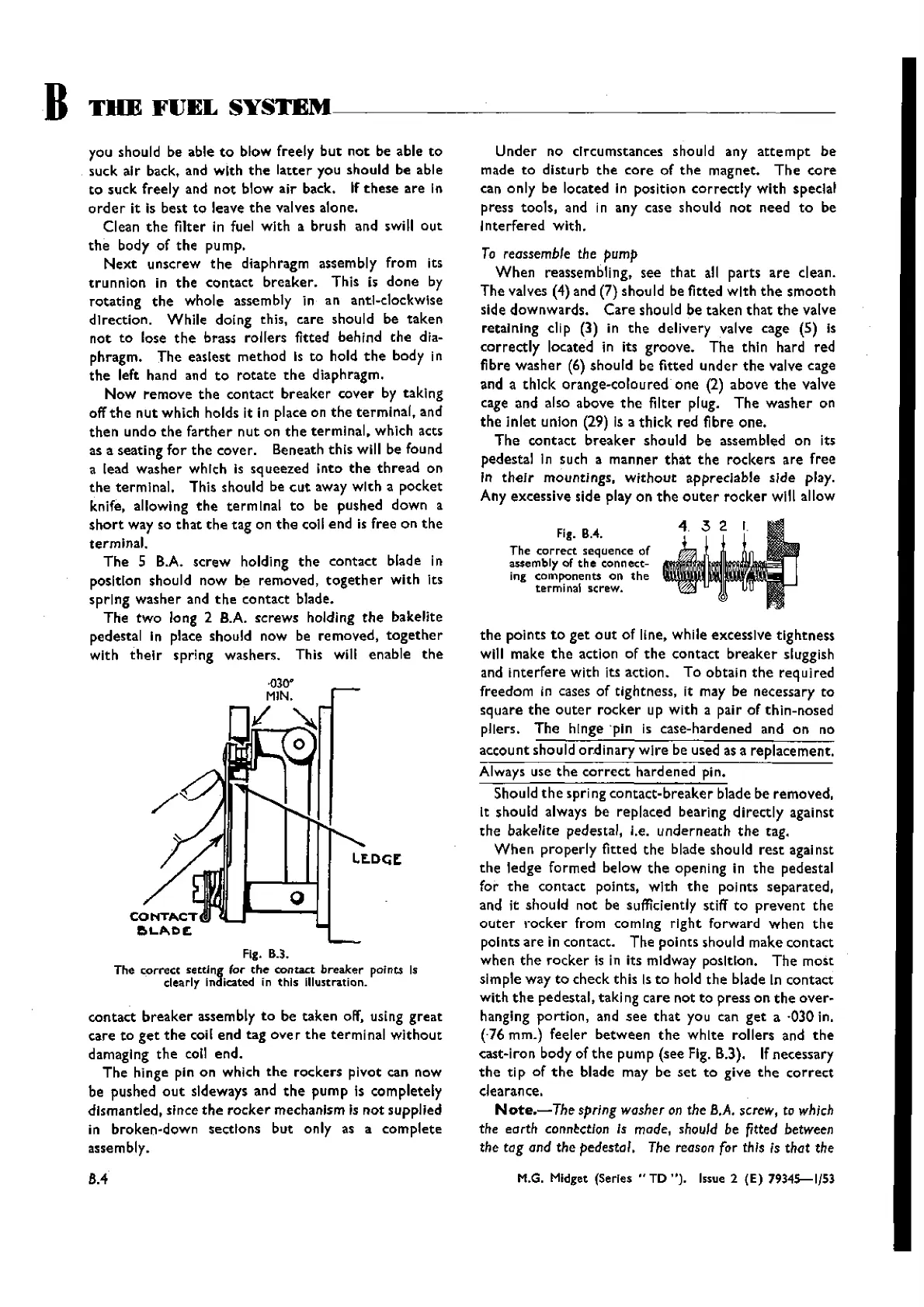

Fig. BA.

The

correct

sequence of

assembly of

the

connecc-

ing components on

the

terminal screw.

the

points

to

get

out

of line. while excessive tightness

will make

the

action of

the

contact

breaker

sluggish

and

interfere

with its action. To obtain

the

required

freedom

in cases of tightness, it may be necessary

to

square

the

outer

rocker

up with a pair of thin-nosed

pliers.

The

hInge ·pln Is case-hardened and on no

account should

or.dinary

wire

be used as a replacement.

Always use

the

correct

hardened pin.

Should

the

spring

contact-breaker

blade be removed,

It should always be replaced bearing directly against

the

bakelite pedestal, I.e,

underneath

the

tag.

When

properly

fitted

the

blade should

rest

against

the

ledge formed below

the

opening in

the

pedestal

for

the

contact points, with

the

points separated,

and it should

not

be sufficiently stiff

to

prevent

the

outer

rocker

from coming

right

forward

when

the

points

are

in contact. The points should make contact

when

the

rocker

is in its midway position.

The

most

simple way

to

check this Is

to

hold

the

blade In contact

with

the

pedestal, taking care not

to

press on

the

over-

hanging portion, and

see

that

you can

get

a ·030in.

(-76

mm.) feeler

between

the

white

rollers and

the

cast-iron body of

the

pump (see Fig.

B.3).

Ifnecessary

the

ti p of

the

blade may be

set

to

give

the

correct

clearance.

Note.-The

springwasheron the

B.A.

screw, to which

the earth

conn~ctlon

Is made,

should

be fitted

between

the tag and the pedestal. The

reason

for this ;s that the

M.G. Midget

(Series"

TO

").

Issue 2

(E)

79345-1/53

Wishvilles Classic

Automobile Library

Loading...

Loading...