B

THE

FUEL

SYSTEM-----------------

8.6

If a roller

drops

out

of position

it

will

get

trapped

between

the

two

ports, and this will

cut

a hole In

the

diaphragm.

Make

sure

th:lt

the

cast-Iron body Is seating

properly

on

the

main body, and Insert

the

five

coupling screws and

the

earth

terminal screw.

These

screws should

not

be screwed up tightly

In che first Instance as It Is absolutely necessary

at this stage to

stretch

the

dIaphragm to Its

outermost

position. This Is best effected by

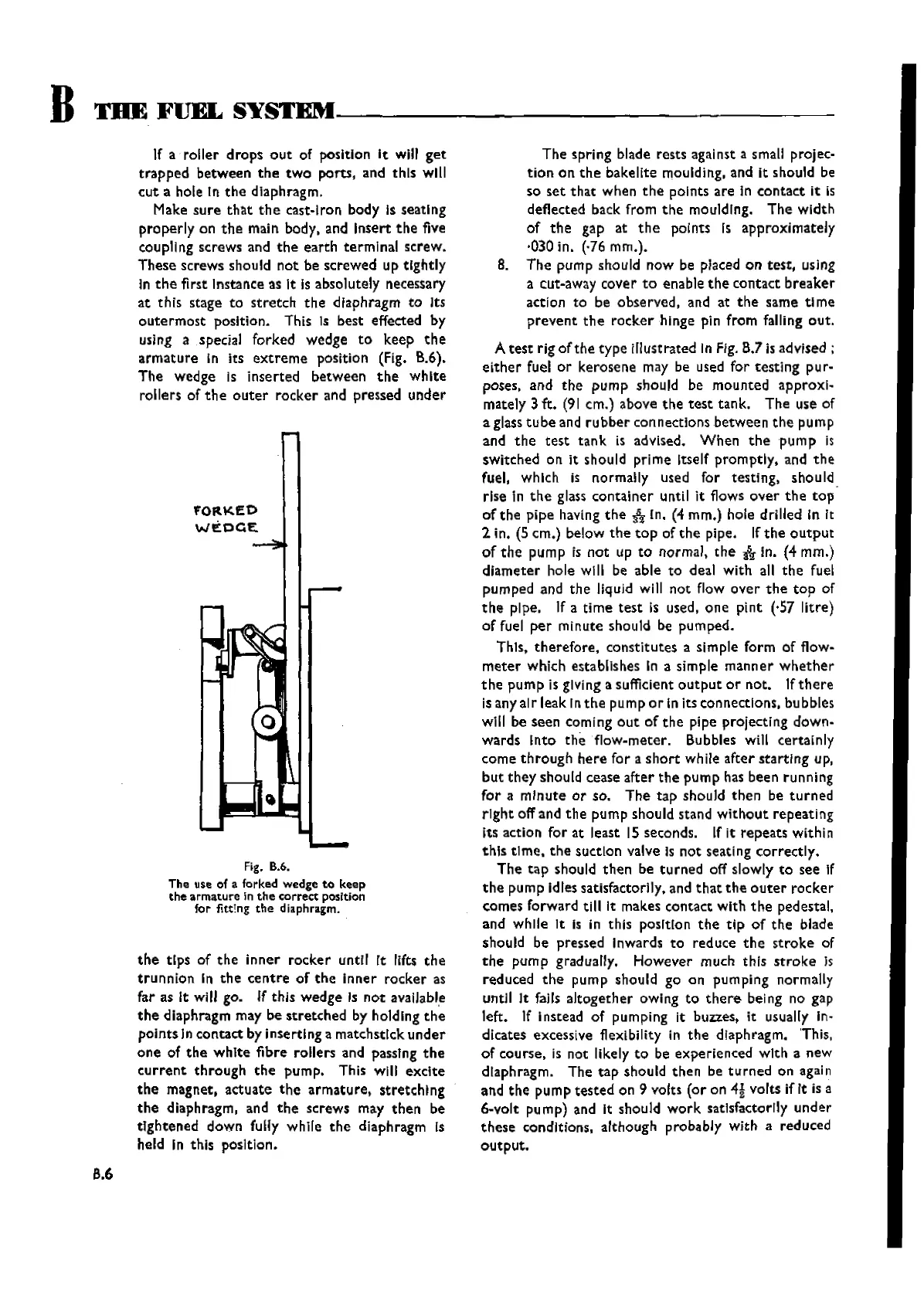

using a special forked wedge

to

keep

the

armature

In its

extreme

position (Fig. B.6).

The

wedge Is Inserted between

the

white

rollers of

the

outer

rocker

and pressed

under

'FORKED

WEOGE

Fig. 8.6.

The use of a forked wedge to keep

the

armature

in

the

correct

position

for fittIng

the

diaphragm.

the

tips of

the

inner

rocker

until rt lifts

the

trunnion

In

the

centre

of

the

inner

rocker

as

far as It will go. If this

wedge

Is

not

available

the

diaphragm may be

stretched

by holding

the

points In contact by inserting a matchstick

under

one

of

the

white

fibre rollers and passing

the

current

through

the

pump. This will

exclte

the

magnet,

actuate

the

armature,

stretching

the

diaphragm, and

the

screws may

then

be

tightened

down fully while

the

diaphragm Is

held In this posItIon.

The

spring blade rests against a small projec-

tion

on

the

bakelite moulding, and It should be

so

set

that

when

the

points

are

In

contact

it is

deflected back from

the

moulding.

The

width

of

the

gap at

the

points Is approximately

·030in. (,76 mrn.],

B.

The

pump should now be placed on

test,

using

a cut-away cover

to

enable

the

contact

breaker

action

to

be observed, and at

the

same

time

prevent

the

rocker

hinge pIn from falling

out.

A

test

rig of

the

type

illust rated In Fig. B.7 is advised ;

either

fuel or kerosene may be used for

testing

pur-

poses, and

the

pump

should be mounted approxl-

rnately 3 ft.

(91

em.) above

the

test

tank. The use of

a glass

tube

and

rubber

connections

between

the

pump

and

the

test

tank. is advised.

When

the

pump

Is

switched on it should prime Itself promptly, and

the

fuel, which is normally used for testing, should

rise In

the

glass

container

until it flows

over

the

top

of

the

pipe having

the

:&

In. (4 mm.) hole drilled in It

2 in. (5 crn.) below

the

top

of

the

pipe. If

the

output

of

the

pump is

not

up

to

normal,

the

"*

in. (4 mrn.)

diameter

hole will be able

to

deal with all

the

fuel

pumped and

the

liquid will

not

flow

over

the

top

of

the

pipe. If a

time

test

is used,

one

pint

(·57 litre)

of fuel

per

minute should be pumped.

This,

therefore,

constitutes a Simple form of flow-

meter

which establishes In a simple

manner

whether

the

pum

pIs

glving a sufficient

output

or

not. Ifth ere

is any alr leak In

the

pump 0 r In Its con nectlons, bubbles

will be seen coming

out

of

the

pipe projecting down-

wards Into

the

flow-meter. Bubbles will certainly

come

through

here

for a

short

while

after

starting

up,

but

they

should cease

after

the

pump has been running

for

a

minute

or

so.

The

tap

should

then

be

turned

right

off and

the

pump should stand

without

repeating

its action for at Ieast 15 seconds. If It

repeats

within

this

time.

the

suction valve Is

not

seating

correctly.

The

tap

should

then

be

turned

off slowly

to

see If

the

pump idles satisfactorily. and

that

the

outer

rocker

c.omes forward till it makes contact with

the

pedestal,

and while It

Is in this posItIon

the

tip

of

the

blade

should be pressed Inwards

to

reduce

the

stroke

of

the

pump

gradually. However much this

stroke

Is

reduced

the

pump should go on pumping normally

until It fails

altogether

owing

to

there

being no gap

left. If instead of pumping It buzzes, it usually ln-

dicates excessive flexibility in

the

diaphragm. 'This,

of course, Is not likely

to

be experienced with a new

diaphragm. The

tap

should

then

be

turned

on again

and

the

pump

tested

on 9 volts

(or

on

4!

volts if It is a

6-volt pump) and it should

work

satisfactorily

under

these

conditions, although probably with a reduced

output.

Wishvilles Classic

Automobile Library

Loading...

Loading...