------

.---THE

IGNITION

EQUIPMENT

C

Whenever

possible,

sparking

plugs should be

cleaned in a special plug

cleaner

of

the

type

supplied

by

the

plug

manufacturer.

Oily

plugs should be

washed

with

petrol

first. A

compressed

air Jet should

then

be used

to

remove

any abrasive from

the

Interior

of

the

plug body and

the

insulator.

If a plug

cleaner

is

not

available, a

wire

brush

is

the

best

substitute.

This

should

also be used

to

clean any accumulation of

carbon

from

the

threads.

The

thread

portion

of

the

plug body is

often

neglected

when

cleaning

owing

to

the

fact

that

it is

not

generally realised

that,

like

the

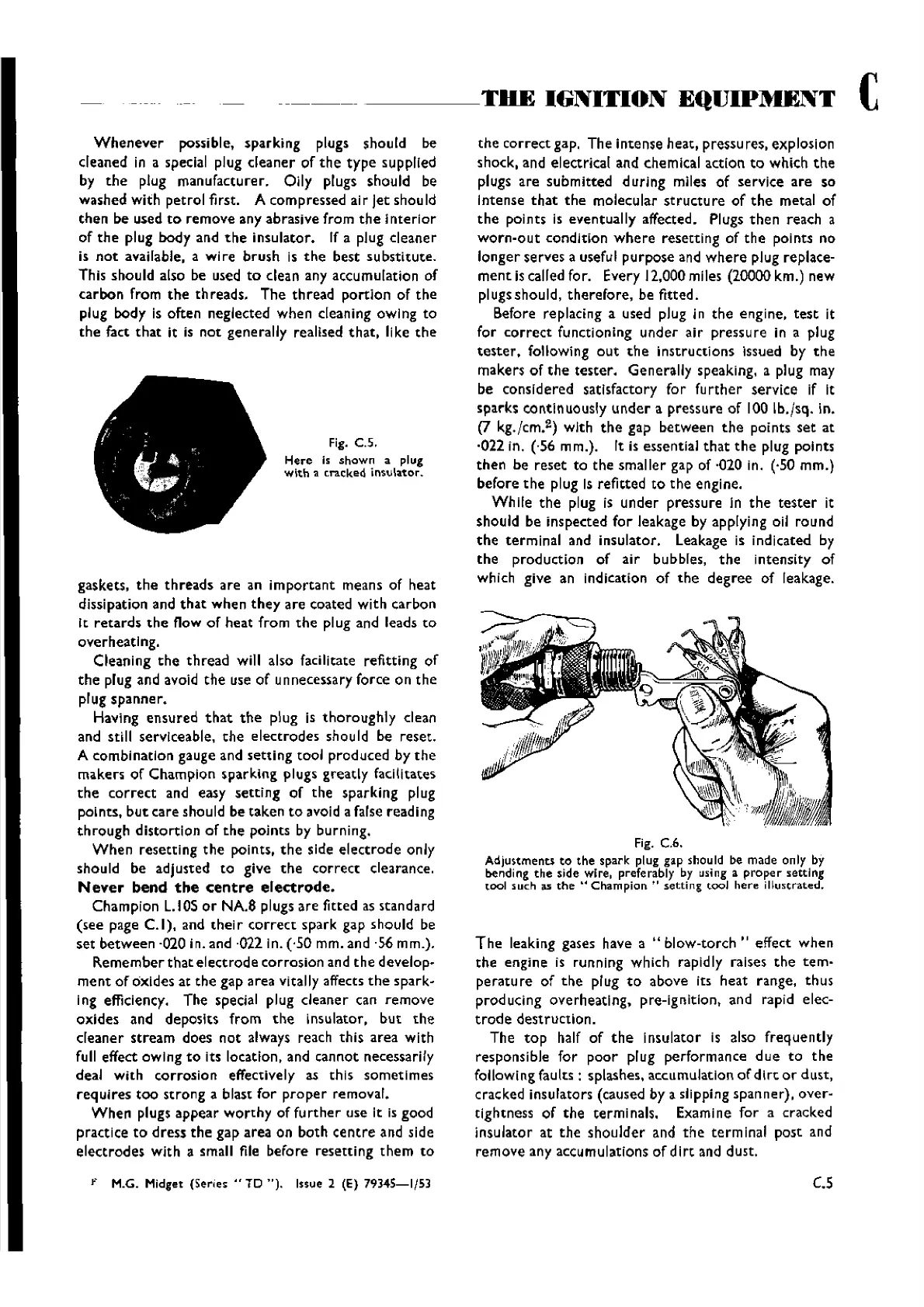

Fig. c.s.

Here

is shown a plug

with

a

cracked

insulator.

gaskets,

the

threads

are

an

important

means of heat

dissipation and

that

when

they

are

coated

with

carbon

It

retards

the

flow

of

heat

from

the

plug and leads

to

overheating.

Cleaning

the

thread

will also facilitate refitting

of

the

plug and avoid

the

use

of

unnecessary force on

the

plug

spanner.

Having

ensured

that

the

plug is

thoroughly

clean

and

stiII serviceable,

the

electrodes

sh0 uId be

reset.

A

combination

gauge and

setting

tool

produced

by

the

makers

of

Champion

sparking

plugs

greatly

facilitates

the

correct

and easy

setting

of

the

sparking

plug

points,

but

care

should be

taken

to

avoid a false reading

through

distortion

of

the

points

by burning.

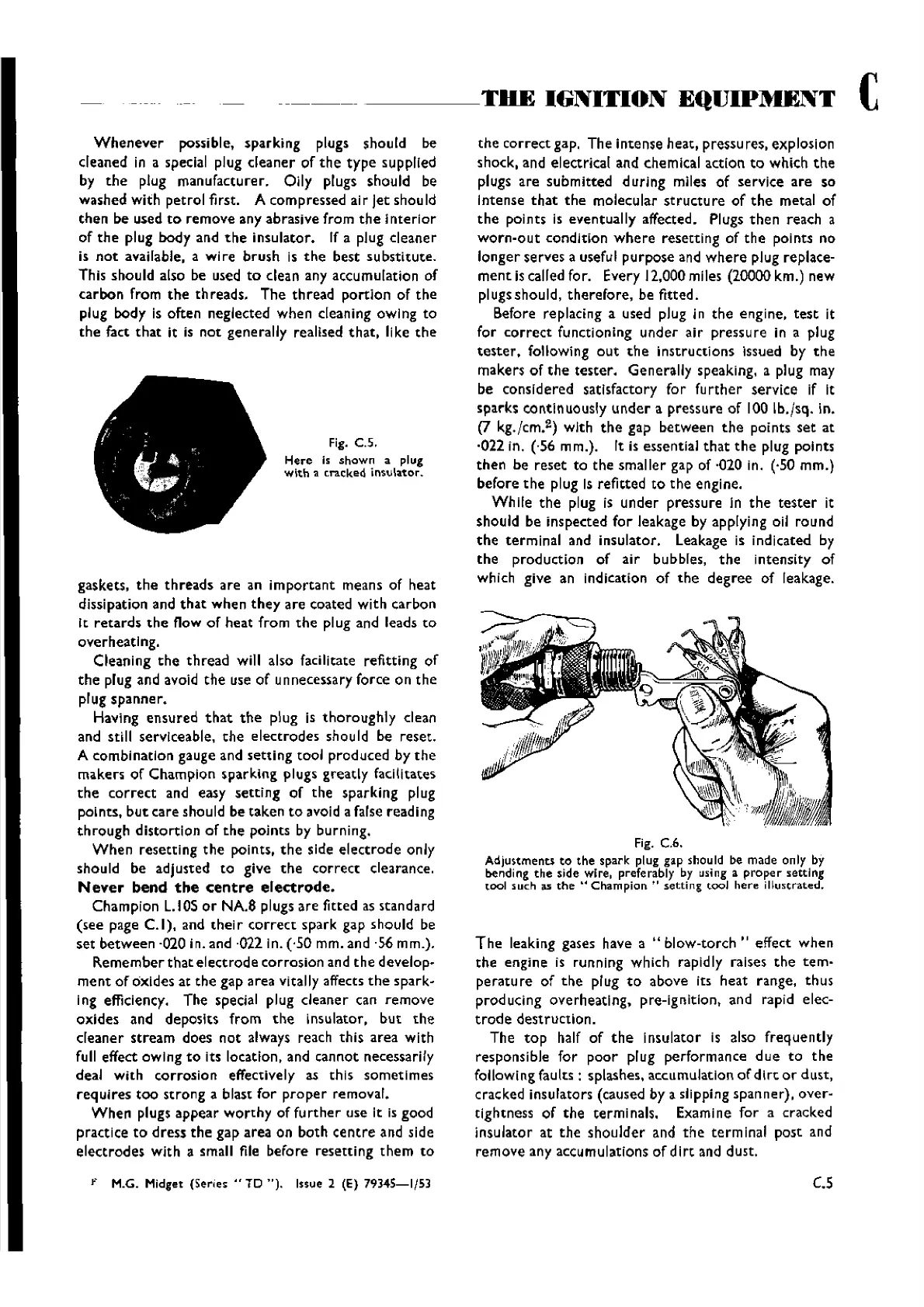

When

resetting

the

points,

the

side

electrode

only

should be

adjusted

to

give

the

correct

clearance.

Never

bend

the

centre

electrode.

Champion

L.IOS

or

NA.8 plugs

are

fitted as

standard

(see

page

CI),

and

their

correct

spark

gap

should

be

set

between

·020 in. and ·022 in. (,50 mm. and ·56

mm.).

Remember

that

electrode

corrosion

and

the

develop.

ment

of

oxides

at

the

gap

area

vitally affects

the

spark-

ing efficiency. The special plug

deaner

can

remove

oxides

and

deposits

from

the

insulator,

but

the

deaner

stream

does

not

always reach

this

area

with

full effect

owing

to

its location, and

cannot

necessarily

deal

with

corrosion

effectively as

this

sometimes

requires

too

strong

a blast

for

proper

removal.

When

piugs

appear

worthy

of

fu

rthe

r use it is good

practice

to

dress

the

gap

area

on

both

centre

and side

electrodes

with

a small file

before

resetting

them

to

F M.G. Midget {Series" TD "J. Issue 2 (E)

79345-1/53

the

correct

gap. The i

nte

nse

heat,

p

ressu

res,

exp

loslon

shock, and electrical and chemical

action

to

which

the

plugs

are

submitted

during

miles

of

service

are

so

Intense

that

the

molecular

structure

of

the

metal of

the

points is

eventually

affected. Plugs

then

reach a

worn-out

condition

where

resetting

of

the

points no

longer

serves

a useful

purpose

and

where

plug replace-

ment

is called for. Every 12,000 miles (20000 km.) new

piugs

should,

therefore,

be

fitted.

Before replacing a used plug in

the

engine,

test

it

for

correct

functioning

under

air

pressure in a plug

tester,

follow! ng

out

th e i

nstru

ctl

ons

issued by

the

makers

of

the

tester.

Generally

speaking, a plug may

be

considered

satisfactory

for

fu

rther

service

if it

sparks

continuously

under

a

pressure

of

100

lb.jsq,

in.

(l

kg·/cm.

2

)

wlth

the

gap

between

the

points

set

at

·022 in.

(-56

mm.). It is essential

that

the

plug points

then

be

reset

to

the

smaller

gap of ·020 in. (·50

mm.)

before

the

plug Is

refitted

to

the

engine.

While

the

plug is

under

pressure

In

the

tester

it

should be inspected

for

leakage by applying oil

round

the

terminal

and

insulator.

Leakage is indicated by

the

production

of

air

bubbles,

the

intensity

of

which give an indication

of

the

degree

of leakage.

Fig. C,6.

Adjustmenu

to

the spark plug gap should be made only by

bending

the

side wi re, prefe rably by us;ng a prope r settlng

tool

such

as

the"

Champion"

setting

tool

here

illustrated.

The

leaking gases have a

"blow-torch"

effect

when

the

engine is running which rapid Iy raises

the

tem-

perature

of

the

plug

to

above

its

heat

range,

thus

producing

overheating,

pre-ignition, and rapid elec-

trode

destruction.

The

top

half

of

the

Insulator is also

frequently

responsible

for

poor

plug

performance

due

to

the

foHowing

faults:

splashes, accumulation

of

dirt

or

dust,

cracked insulators (caused by a slipping

spanner),

over-

tightness

of

the

terminals.

Examine

for

a

cracked

insulator

at

the

shoulder

and

the

terminal

post

and

remove

any accumulations

of

dirt

and

dust.

c.s

Wishvilles Classic

Automobile Library

Loading...

Loading...