10

PLEASE NOTE: If you have purchased a Trak-Star speed

sensor, disregard the section on magnetic speed sensors

and install the Trak-Star as described in the instructions

packed with the unit.

Locations where the sensor may be installed:

1. Non-driven wheel on tractor, vehicle or implement. This

is less susceptible to errors resulting from wheel slip.

2. Tractor, vehicle or planter drive shaft. This type of

mounting is recommended for trucks, four-wheel drive

tractors or other equipment that has poor or no access

to a non-driven wheel.

Installation (cont)

Speed Sensor Installation

Locate the Following Parts:

• Speed Sensor Cable

• Mounting “L” Bracket

• Magnet Clips

• Magnets

• Cable Ties

Magnets

Please read the following information about magnet spacing

and polarity.

The number of magnets that must be used depends on

where you mount the sensor. The general rule for tractor

or implement wheels is one magnet for each wheel bolt

(minimum of two, and always use an even number). For drive

shafts or small wheels (ATV’s), a minimum of two magnets

are required.

The magnets provided by Micro-Trak are marked with

a dashed line on the SOUTH pole side of the magnet.

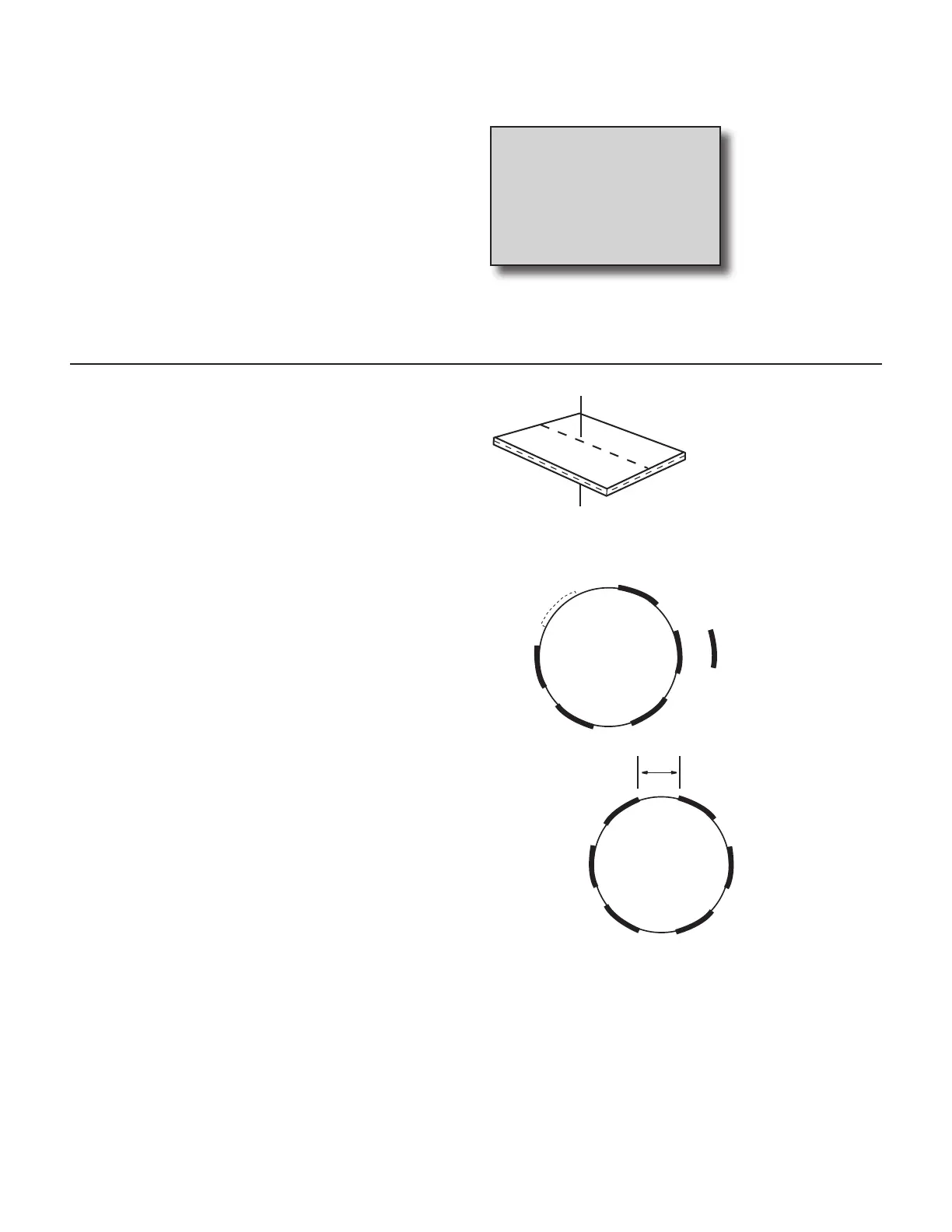

See Illustration 3A.

Always use an even number of magnets, and always alternate

the polarities of the magnets as you go around the wheel

hub or drive shaft.

To install, mount the first magnet with the SOUTH pole side

(dashed line) facing toward the hub or shaft. Mount the

second magnet with the NORTH pole side facing toward the

hub or shaft. See Illustration 3B.

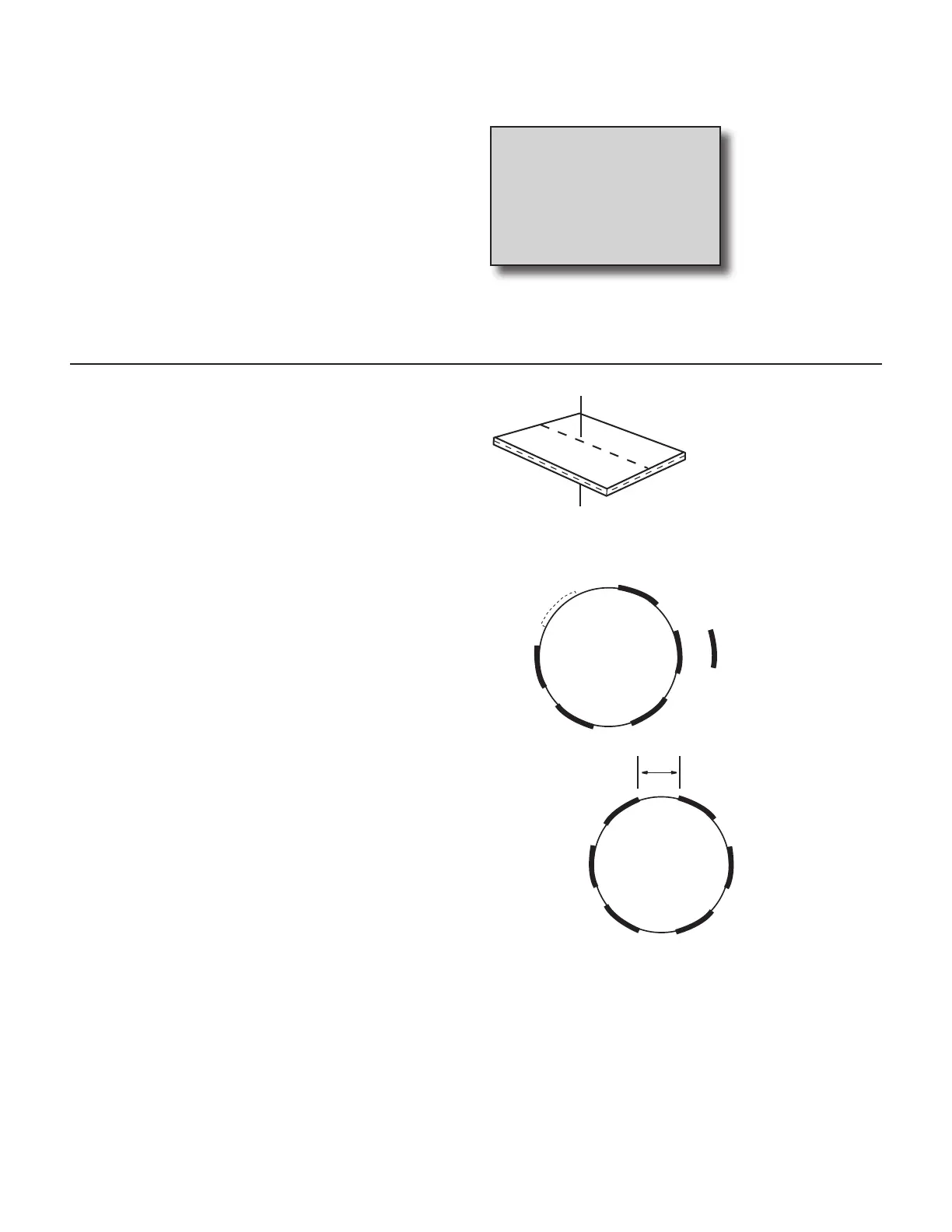

For proper operation, the magnets must be evenly spaced

around the wheel or drive shaft. The magnets must be at

least 1” apart. See Illustration 3C.

Illustration 3A

Illustration 3C

Illustration 3B

N

North

North

North

South

South

South

1

2

4

3

5

6

should alternately

attract and repel.

1” Minimum

Loading...

Loading...