19

CIRC: This position is used to calibrate the speed sensor

for ac cu rate speed and dis tance measurement. When this

position is selected, the display will alternately show, every

three seconds, the wheel

circumference value and

the distance value. The

wheel circumference value

is the number shown along with “CAL” on the

display. See Illustration 17B. The distance

value is the number shown when “CAL” is not shown on the

display. Either one may be selected to calibrate for speed

and distance measurement. Select by pressing the “+” or “-”

button when the desired value is being displayed.

Working Width

Banding Application Calibration

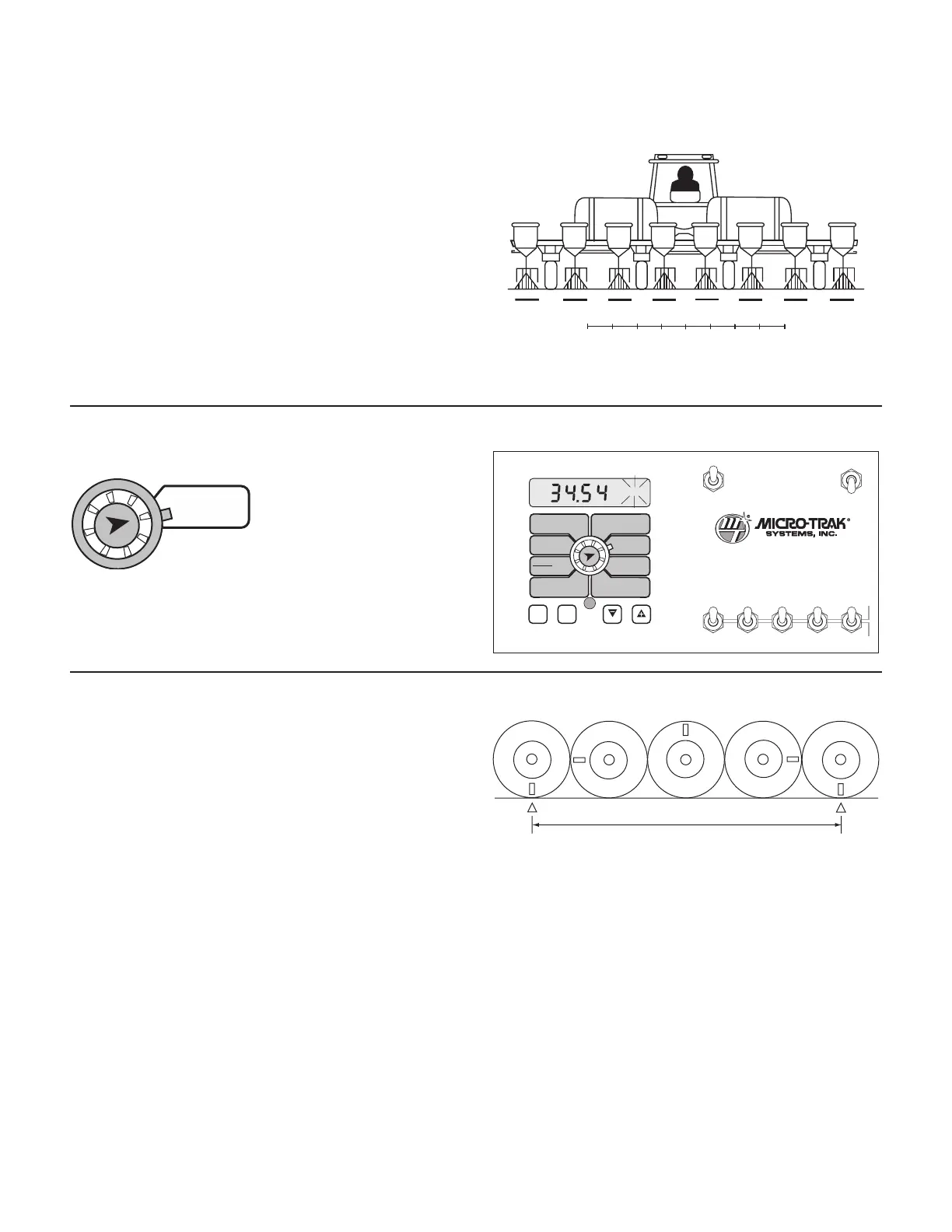

In banding applications, you will still need to enter the total

width of each boom section so that area counts correctly, but

you must also calculate the percentage of your total width

the band is covering and reduce your target rate to match.

For example, if you are planting with an eight-row planter

with 30-inch spacing, your total working width, regardless

of the width of bands, is 240 inches (8 x 30 inches). Now, for

purposes of this example, you have eight 12” bands. Your

total band coverage is 96 inches (8 x 12 inches). Based on

that, your band is covering 40 percent of your total width

(96 divided by 240). If you want to apply 20 GPA in the

band, enter 8 GPA as your target rate (40 percent of 20 GPA).

See Illustration 17A.

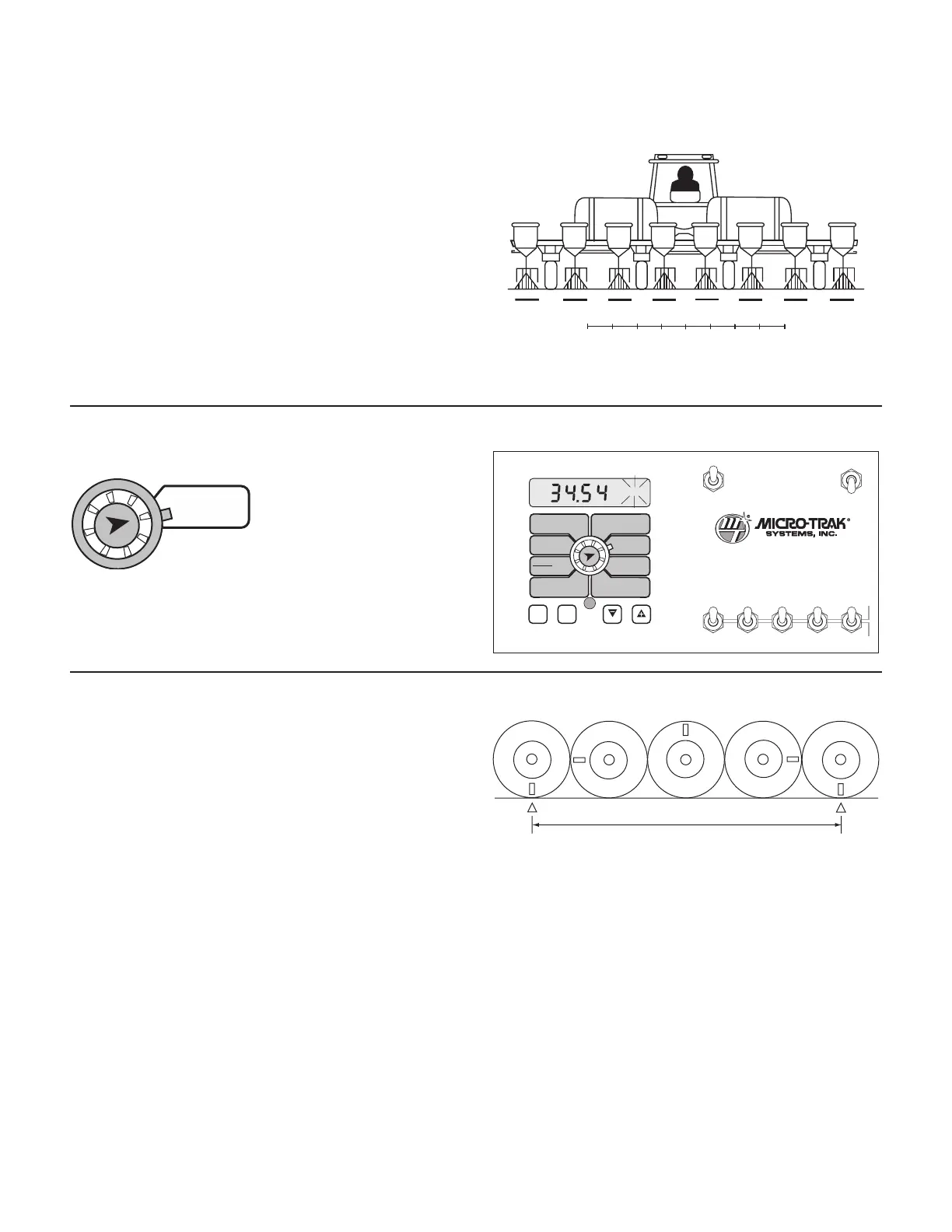

To determine circumference, measure the

distance of one complete wheel revolution

and divide by the number of magnets installed .

Determining Wheel Circumference

For the console to calculate the correct number of acres

(hectares), both the circumference of the sen sor-equipped

wheel and the implement width must be entered. Determine

the circumference of the sensor-mounted wheel to the

nearest tenth of an inch (thousandth of a meter) with the

fol low ing method:

METHOD

Mark tire with a piece of chalk and mea sure distance traveled

on the ground for one com plete rev o lution. See Illustration 19.

For accuracy, measure the wheel rev o lu tion sever al times and

take the average. Divide that val ue by the num ber of magnets

installed on the wheel hub to get your starting wheel cir cum-

fer ence (CIRC) calibra tion val ue.

Illustration 17A

Illustration 17B

Illustration 18

Calibration (cont)

Entering Calibration Values (cont)

+

+

+

+

+

+

+

WIDTHBOOM

SELECT

TEST

SPEED

ADJUST

RATE

TARGET

RATE

CIRC

MIN

FLOW

FLOW

CAL

SPEED

DISTANCE

FLOW

RATE

TOTAL AREA

APP. RATE TOTAL FLOW

SUB AREA

ON

OFF

ON

OFF

12345

B O O M S

RUN

HOLD

AREA

HOUR

CAL

AUTO

MAN

RESET

MT-3405

™

F

AUTOMATIC RATE CONTROLLER

MANAUTO

CALHOLD

V 1 2 3 4 5

CIRC

DISTANCE

Loading...

Loading...