9

Introduction

MT-3405 FTW

Select a mounting location which seems most workable,

and that best fits your needs. It should be con ve nient to

reach and high ly vis i ble to the op er a tor. DO NOT IN STALL

IN A PO SI TION THAT OB STRUCTS THE VIEW OF THE ROAD

OR WORK AREA. Whenever pos si ble, avoid lo ca tions that

expose the con sole to direct sun light, high tem per a ture,

strong chemicals or rain.

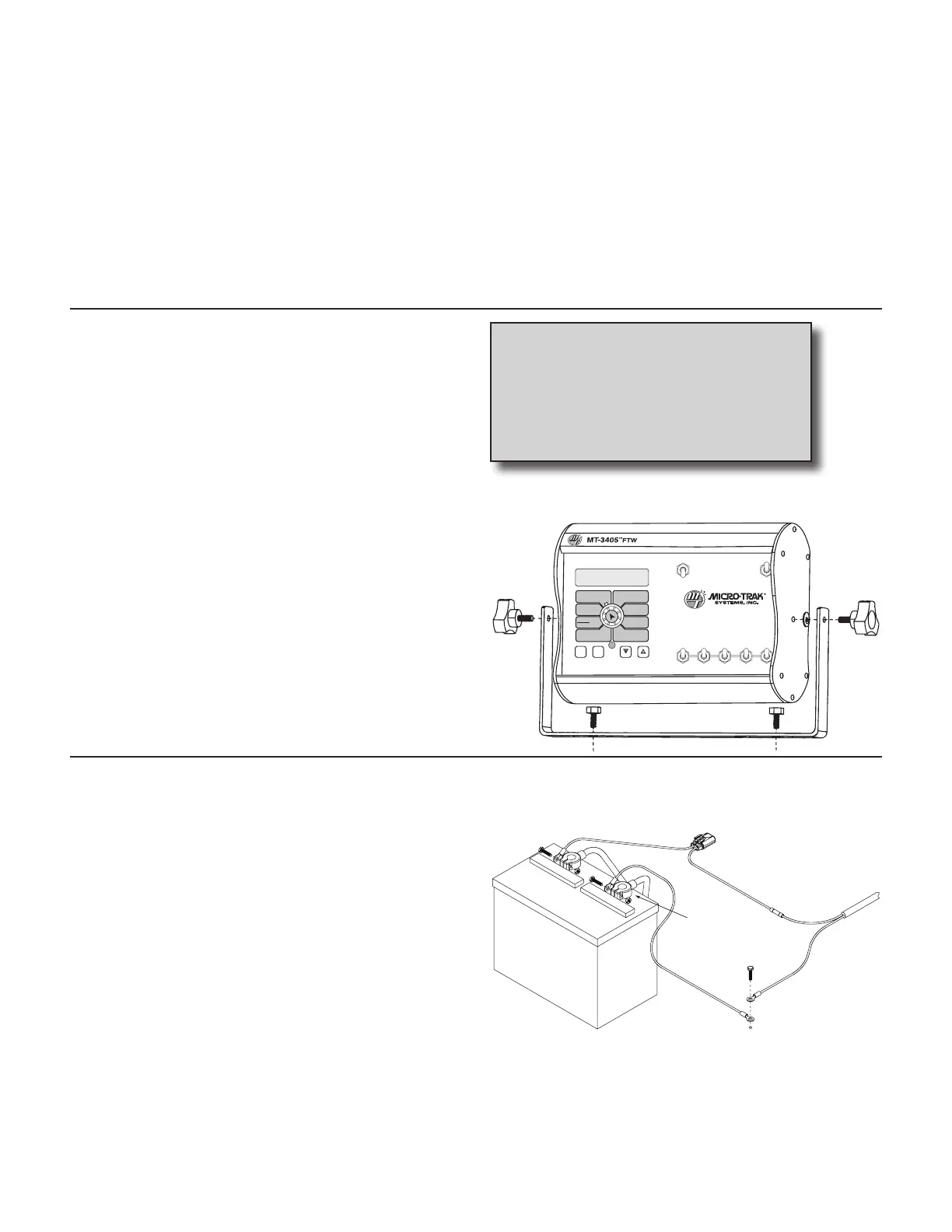

Place the mounting bracket in the selected lo ca tion, mark

holes, drill 1/4” (7mm) holes and mount bracket with bolts,

lock wash ers and nuts pro vid ed. (If bolts are not practical, use

self-tapping screws.) See Illustration 1.

Insert the console in the “U” bracket and install the console

knobs through the bracket, placing a rubber washer over the

threaded stud. Position console to proper viewing angle and

tighten the knobs securely.

Illustration 1

Tools Needed to Install MT-3405 FTW

• Screwdrivers • Pliers

• Set of Wrenches • Wire Cutter

• Electric Drill and Bits • Hammer

• 12-Volt Test Light • Hacksaw

• Center Punch • Bench Vise

The MT-3405 FTW is a flow-based control system which is

designed to be used on sprayers with diverting (three-way)

boom valves.

Using typical boom valves and a Micro-Trak flow-based rate

control system, when one of more of the boom sections are

turned off, the flow of liquid is discontinued to that boom

section, and flow is adjusted through the remaining boom

sections so that application rate (when in automatic) is not

affected.

Using the diverting (three-way) valve and the MT-3405 FTW

flow-based control system, liquid is actually diverted or

by-passed back to the tank. With the special “FTW” software,

the MT-3405 FTW counts only the liquid that has been

sprayed.

The MT-3405 FTW system uses individually entered boom

widths to determine which portion of the total liquid is being

by-passed rather than sprayed from the boom section. For

this reason, it is extremely important to adjust and verify

the amount of liquid that is diverted by the three-way valve

when a boom is shut off. Please read your sprayer’s operating

manual for details, or see Appendix C for basic instructions.

Installation

Mounting the Display Console

WIDTHBOOM

SELECT

TEST

SPEED

ADJUST

RATE

TARGET

RATE

CIRC

MIN

FLOW

FLOW

CAL

SPEED

DISTANCE

FLOW

RATE

TOTAL AREA

APP. RATE TOTAL FLOW

SUB AREA

ON

OFF

12345

B O O M S

RUN

HOL

AREA

HOUR

CAL

AUTO

MAN

RESET

MT-3405

™

F

AUTOMATIC RATE CONTROLLER

MANAUTO

CALHOLD

V 1 2 3 4 5

AUTOMATIC SPRAY RATE CONTROLLER

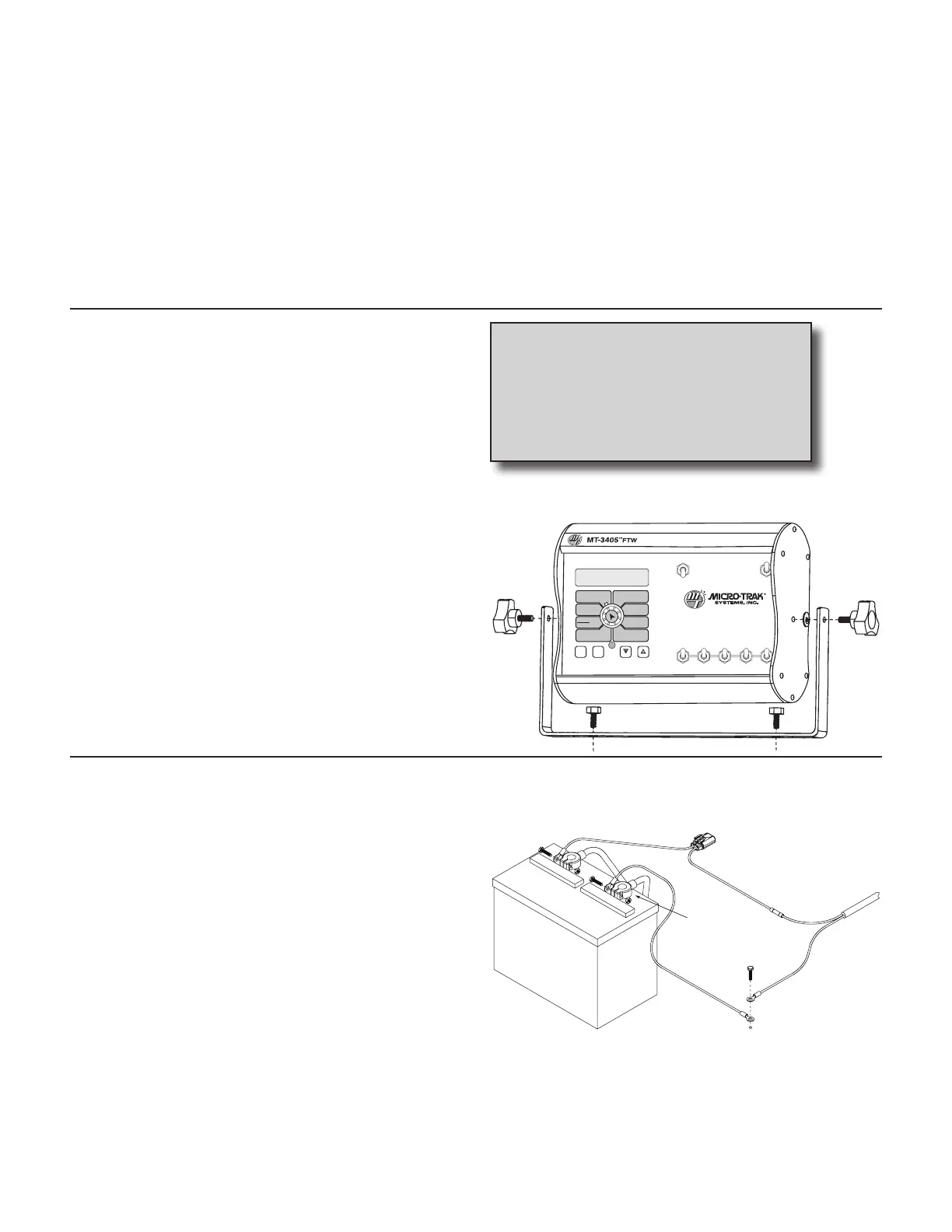

Electrical Installation

The MT-3405 FTW must be connected to a 12-volt DC elec-

tri cal system. Power is connected directly to the battery. The

MT-3405 FTW has an ON/OFF switch on the console to turn

the power off when the system is not being used.

Locate the power cable harness and connect to the mating

connector on the console. Connect the blue chassis ground

wire to a good frame ground. See Illustration 2. Make sure

there is good metal-to-metal contact. Route the power cable

from the console to the battery. Cut off excess length. In

routing cable to battery, avoid ar eas where the ca ble may

be subjected to abra sion or ex ces sive heat. Install the in-line

fuse provided with the kit on the white wire, as illustrated,

to protect the circuit. Connect the WHITE wire (hot) to the

positive battery terminal. At tach the BLACK wire (ground) to

a screw or bolt on the equipment frame. See Il lus tra tion 2. Be

sure there is good metal-to-metal con tact.

Your MT-3405 FTW is equipped with an ad vanced electronic

mem o ry which does not re quire a con stant supply of pow-

er to re tain daily totals or calibration values. The advantage

Hot

(WHITE)

Fuse Required

Chassis Ground

(BLACK)

Ground

Illustration 2

NOTE: For negative ground systems ONLY.

with this type of memory is that it conserves battery power

and will not dis charge the vehicle’s battery when equipment

is not in use.

Loading...

Loading...