13

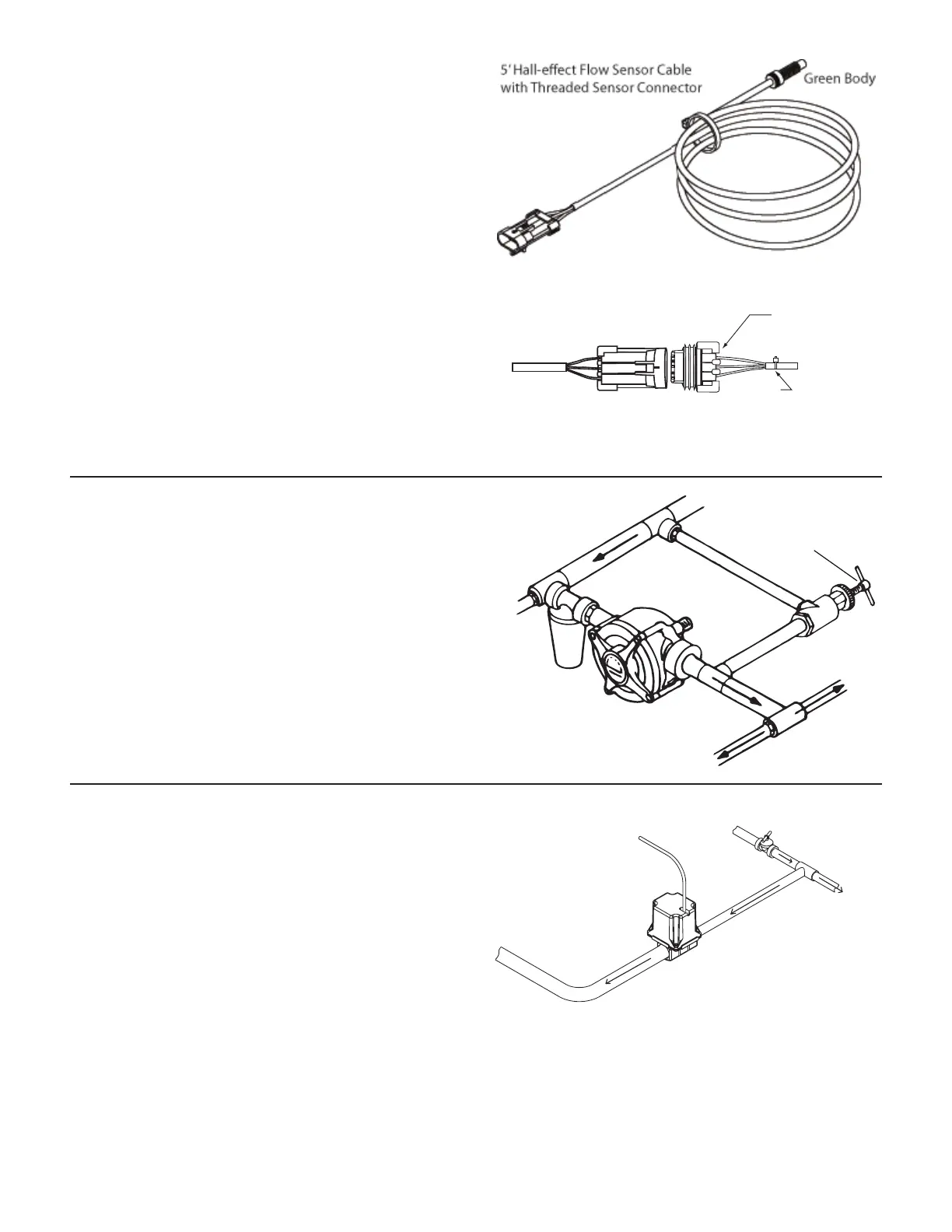

With the flowmeter in place, install the flow sensor cable

(GREEN body).

Screw sensor all the way into hole of flow me ter. Tight en 3/8”

jam nut to lock sen sor in place.

Uncoil flow sensor cable and carefully route it to meet the

main harness flow connector marked with GREEN tie. Align

connectors and press firmly together until locking tab clicks

into place. Secure cable with ties provided. See Illustration 7.

Connect flow sensor cable to green-tie console cable.

Installation (cont)

Installing Flow Sensor Cable

Illustration 7

A B C

C B A

Flow Sensor

Cable Connector

Main Harness

Flow Connector

Green Tie

Pressure Relief Valve

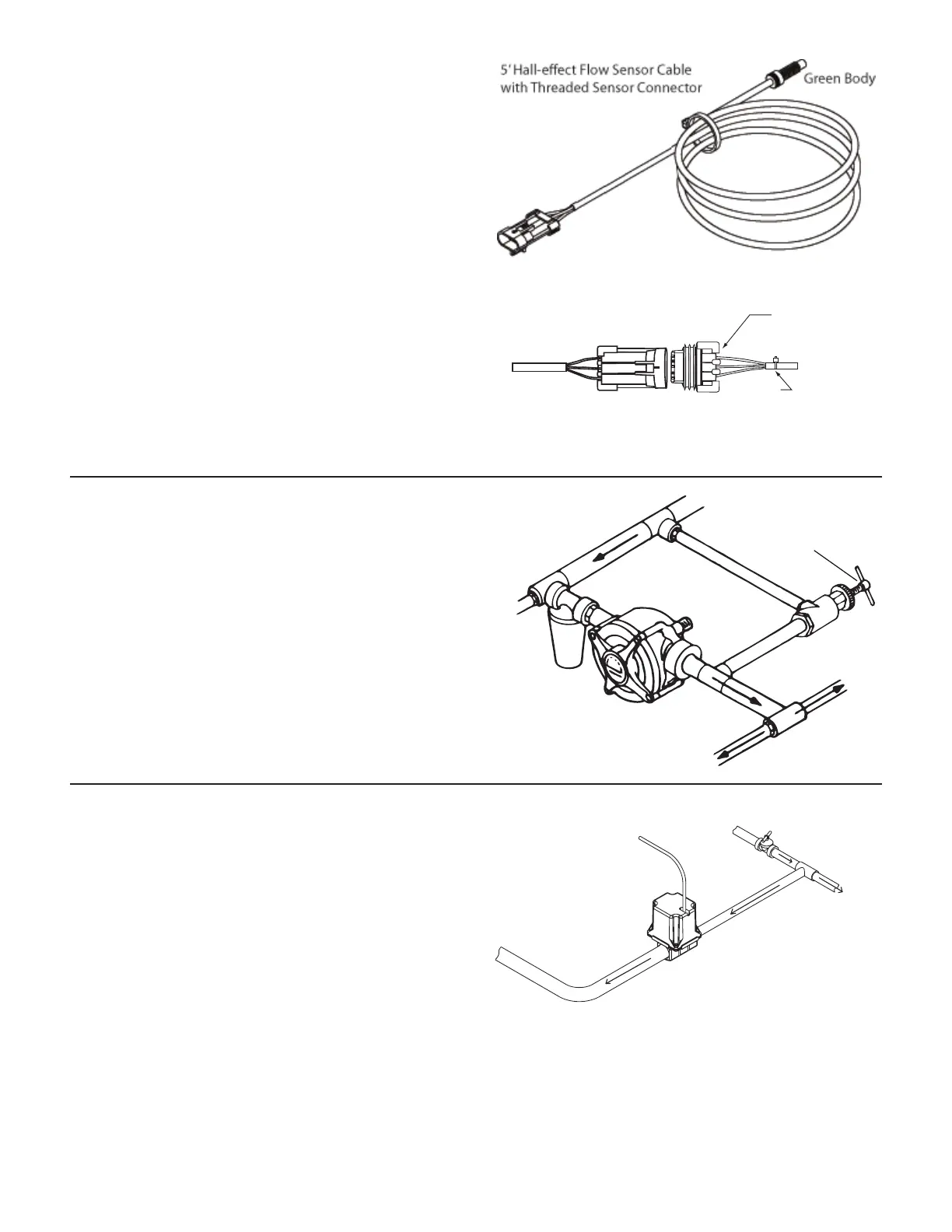

If you have a positive displacement pump or a cen trif u gal

pump capable of generating excessive pressure, you must

in stall a pressure relief valve and adjust it to a safe max i-

mum pressure. If a positive dis place ment pump is operated

without a pressure relief valve, damage may re sult to pump

or other plumbing component. See Illustration 8.

For Positive Displacement Pump

Illustration 8

Tee “C”

Tee “A”

Pressure

Relief Valve

Servo, Throttling Valves

The servo valve installs in an unrestricted return line to the

inlet of the pump or directly into the tank. DO NOT install the

servo valve closer than 12” to the flowmeter. The servo valve

has a flow direction decal on it. Make certain that the actual

flow direction matches the decal on the servo valve. DO NOT

install the servo valve in the agitation line. Slow response

time and marginal operation may result. The return line

should tee from the main line just after the throttling valve.

See Illustration 9. The throttling valve is used to limit the

output (set maximum output) of the pump to the flowmeter

and servo valve. The throttling valve is adjusted to put

the servo valve in its optimal operating range. Please refer

to Pre-Field System Checkout for proper valve adjustment

procedure.

The servo valve connects directly to the main harness 3-pin

W/P cable lead. If more length is required, use a 3-pin W/P

extension cable of the appropriate length. If using a Braglia

Illustration 9

Return to pump

inlet or unrestricted

return to tank

Servo Valve Cable

From Pump

Throttling Valve

To Flowmeter

Servo Valve

or other 12-volt control valve, please refer to 12-Volt Control

Valve Calibration on page 39.

NOTE: The servo valve may be installed in the main spray

line. For in-line installations, you will need to cut the servo

cable and reverse the wires. Connect the RED wire to the

BLACK wire and vice versa. Failure to reverse the wires will

result in the servo valve operating backwards.

Loading...

Loading...