15

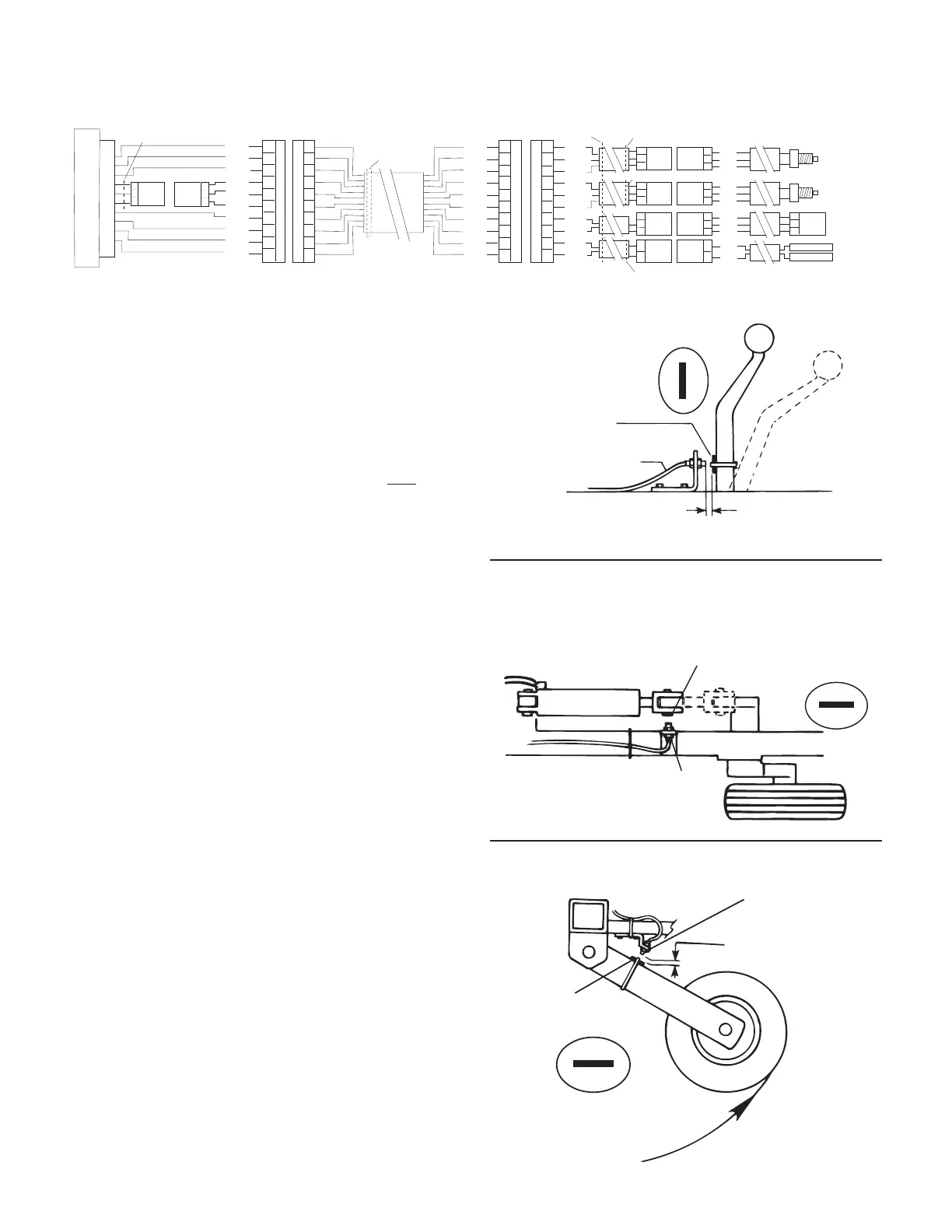

Lift Wheel Mounting

Hydraulic Cylinder Mounting

Remote Run sensor on hydraulic cylinder. Magnet and sensor

are in line when equipment is lowered and operating.

The run/hold sensor cable has a black body and a GRAY tie

near the 3-pin M/P connector and mates with the main har-

ness cable having a GRAY cable tie near the 3-pin M/P con-

nec tor. Make certain that you install the correct sen sor cable

and connect it to the correct connector on the main harness.

The run/hold sensor has a BLACK body. DO NOT use a speed/

flow sensor (GREEN body). See Illustration 13.

• Attach a magnet to a lever or some part of the equipment

that moves when the im ple ment is raised and lowered.

The Hall-effect run/hold sensor is sensitive only to the

south pole (side with dashed line) of the magnet. Check

the polarity of the magnet by bring ing it near the run/

hold sensor with the console turned on. Note and mark

the face of the magnet that is toward the sensor when

the console does not indicate “HOLD.” When the mag net

is away from the sen sor, the con sole will be in HOLD and

will shut off the boom valves and stop count ing acres.

NOTE: The run/hold kit includes a 5’ sensor cable

and 10’ extension. You may re quire additional

extension cables which are avail able in 5 ft. (1.5

m), 10 ft. (3 m), 15 ft. (4.5 m), 20 ft. (6 m) and 25 ft.

(7.6 m) lengths.

• You may also use a toggle or other type switch. Sim ply

cut the blue jumper wire in the dust cover and splice on

an appropriate length of wire to reach your switch.

When switch is closed, console is in RUN. When the switch is

open, the console is in HOLD.

INSTALLATION NOTE: The main harness provides two

connection points for the run/hold. For Run/Hold in stal la-

tions in the cab or near the control con sole, it may be more

prac ti cal to use the local access con nec tor on the control

console pigtail (GRAY tie) ex it ing the rear of the con sole.

Using this connection point will disable the con nec tion

point on the end of the main harness. For run/hold sensor

in stal la tions on im ple ments, it may be more practical

to use the run/hold connector on the end of the main

harness. When using this connection point, make certain

that the local access con nec tor is mated together.

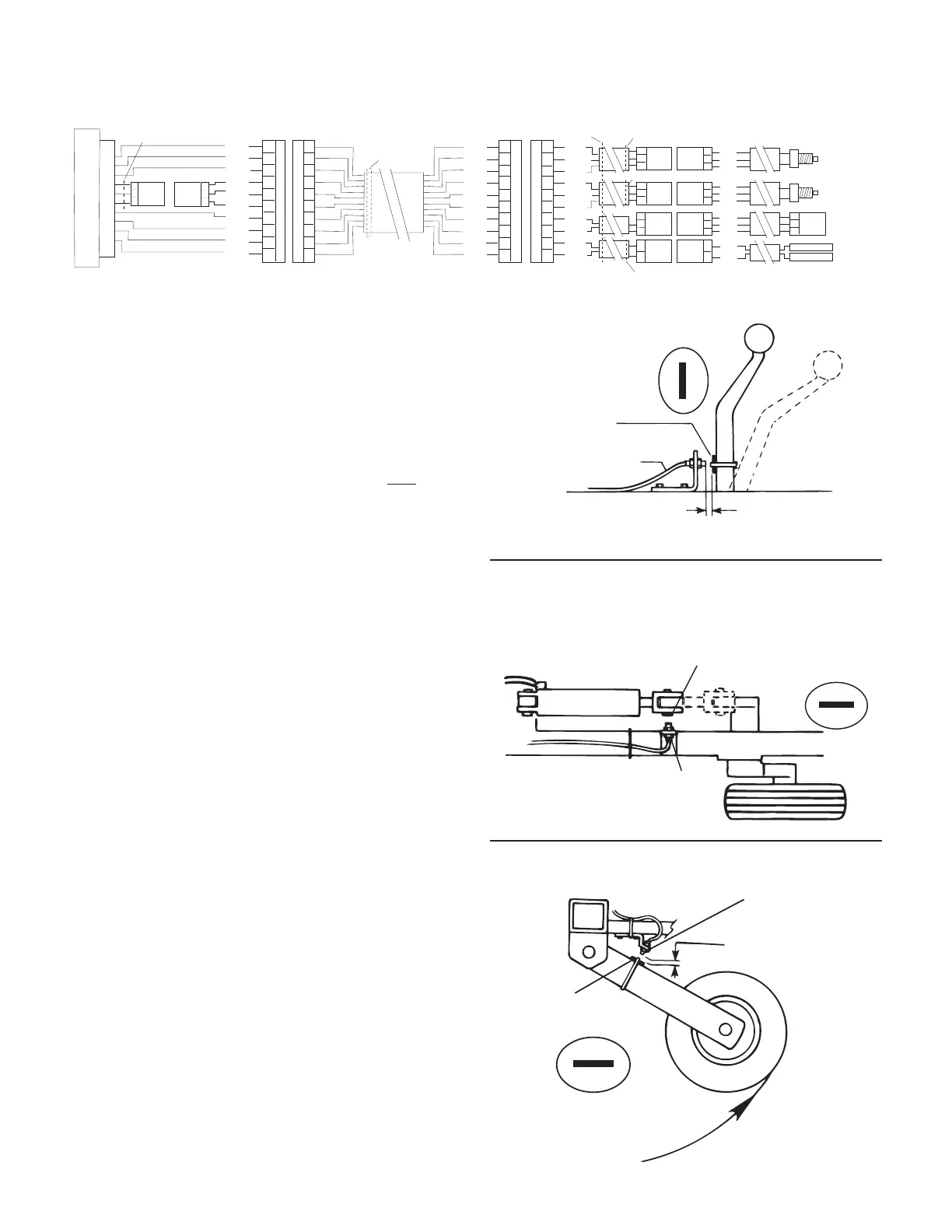

Illustration 13

GREEN TIE

FLOW

SERVO

BOOM ONE

RUN/HOLD

BRN

RED

ORG

YEL

GRN

BLU

VIO

GRY

WHT

BLK

A

B

C

D

E

F

G

H

J

K

10-PIN METRI-PACK TOWER

A

B

C

D

E

F

G

H

J

K

10-PIN METRI-PACK SHROUD

A

B

C

A

B

C

3-PIN

M/P 150

TOWER

LOCAL ACCESS RUN/HOLD CONNECTOR

BROWN TIE

RED TIE

GRAY TIE

GRAY TIE

MT 3405 FTW CONSOLE

3-PIN

M/P 150

SHROUD

BRN

RED

ORG

YEL

GRN

BLU

VIO

GRY

WHT

BLK

A

B

C

D

E

F

G

H

J

K

A

B

C

D

E

F

G

H

J

K

A

B

C

D

E

F

G

H

J

K

10-PIN METRI-PACK TOWER

10-PIN METRI-PACK SHROUD

RED

WHT

BLK

RED

WHT

BLK

RED

BLK

RED

BLK

3-PIN

M/P 150

SHROUD

A

B

C

A

B

C

A

B

C

A

B

C

A

B

C

A

B

C

3-PIN

M/P 150

SHROUD

3-PIN

M/P 150

TOWER

3-PIN

M/P 150

TOWER

3-PIN

W/P 150

TOWER

3-PIN

W/P 150

SHROUD

2-PIN

M/P 150

SHROUD

2-PIN

M/P 150

TOWER

A

B

A

B

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

BLK

A

B

C

3-PIN

W/P 150

SHROUD

FEMALE .250 QD

FEMALE .250 QD

Installation (cont)

Remote Run/Hold

1/8” to 3/8 “ (6 mm to 13 mm)

space when equipment is

Sensor Cable

(black body)

Magnet

South

North

Run Position

Hold

Position

1/8” to 3/8”

(6 mm to 13 mm)

when wheels are up

Magnet

South

North

Run

Position

Hold

Position

Sensor

(Black body)

Magnet

North

South

Rockshaft Control Lever Mounting

Loading...

Loading...