IMPORTANT: Opening the flowmeter will void the

Flowmeter Calibration value assigned to your unit.

However, you may need to take the flowmeter apart for

periodic cleaning or to remove an obstruction.

If you can shake the flowmeter from end-to-end to produce

a “rattling” sound (shaft-end play), and if you can blow

into the meter from either end and cause the turbine to

spin freely, your flowmeter does not need cleaning. If

you cannot hear the “rattling” sound or get the turbine

to spin freely, your flowmeter needs to be cleaned. See

Illustrations 26 & 27 for reassembly instructions.

OPENING FLOWMETER

Cut the calibration tag retaining wire. Remove the screws

and disassemble the flowmeter. Do not attempt to remove

the sleeve bearings from the flowmeter housing.

Use warm water and if necessary, a mild detergent and a

soft bristle brush to clean all parts. Do not use solvents or

diesel fuel to clean the flowmeter. A magnet works well for

removing fine metallic particles from the turbine.

Inspect all parts. Check for excessive bearing or shaft wear.

The shaft will wear shorter until the turbine drags on

the housing. Illustration 25 shows you what a new shaft

looks like. When the shaft is worn to the point of drag, the

turbine must be replaced.

NOTE: The turbines have magnets built into the fins. There

are no visible magnets.

On a flat surface, place each housing half on end. Set and

spin the turbine in each half. It should spin freely. If it does

not spin freely, remove the turbine, wipe the shaft and try

again. If is still does not spin freely, the shaft or bearings may

have excessive wear. (Service may be necessary).

TO ASSEMBLE THE FLOWMETER

Place turbine in non-sensor housing. Coat O-ring with silicon

grease and position O-ring on housing. (O-ring may be

reused a few times, but will eventually need to be replaced).

Carefully set turbine in place. Set other housing half in place.

Drop all screws into holes. Hold nuts in place and finger-

tighten screws. Making sure O-ring is still properly aligned,

evenly tighten all screws. Attach tag.

After assembly, shaking flowmeter end-to-end should

produce a “rattling” sound (shaft end play). Blowing into

the meter from either end should cause the turbine to spin

freely. If the turbine only spins from one direction, install the

flowmeter so that the liquid flows in that direction (service

may be required).

For maximum accuracy the flowmeter should be mounted in

a vertical position. Accuracy of flowmeter readings cannot

be guaranteed for flow rates below two gallons per minute.

Recalibration is required before field operation.

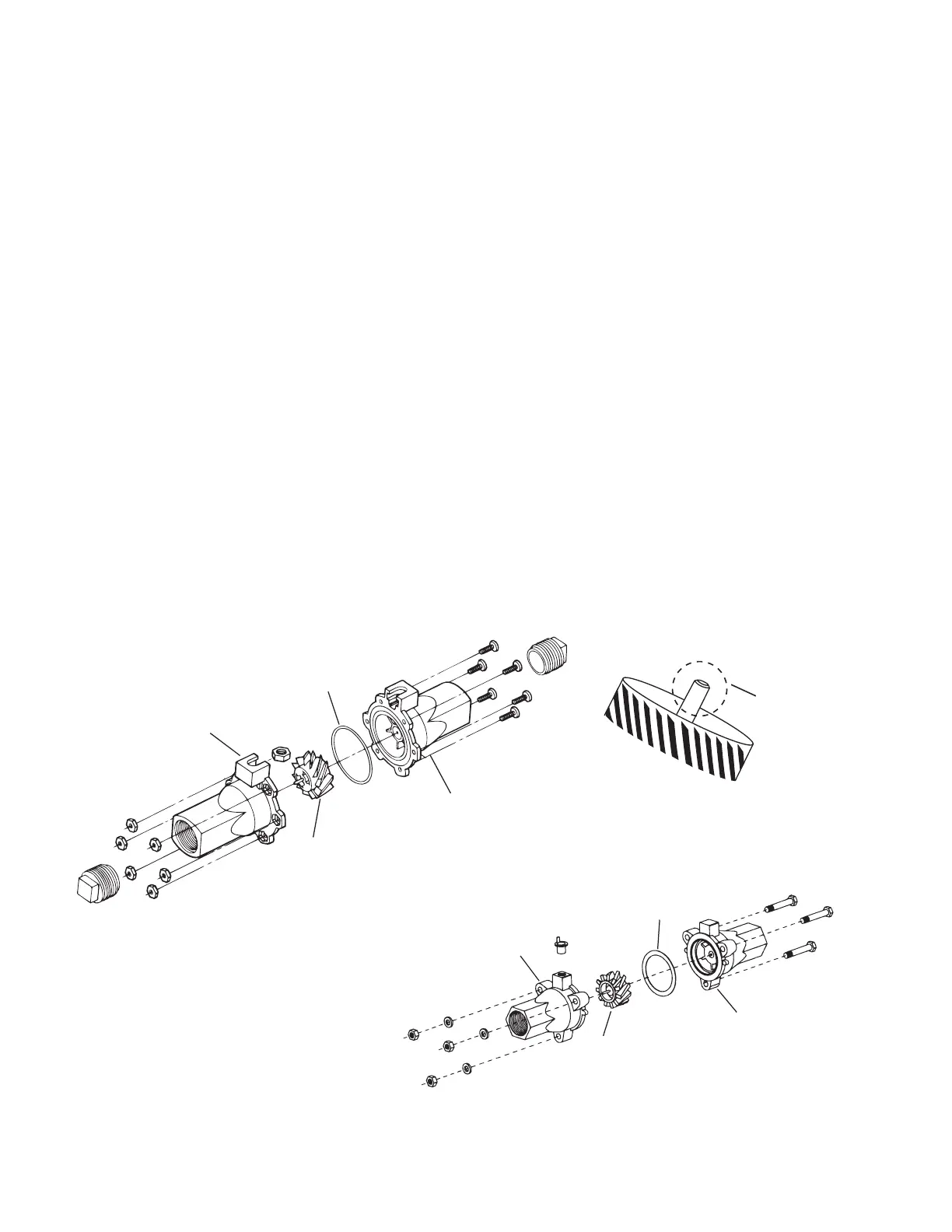

Illustration 27

Complete assembly

FM750 SS Flowmeter

33

Troubleshooting (cont)

Flowmeter Cleaning and Assembly

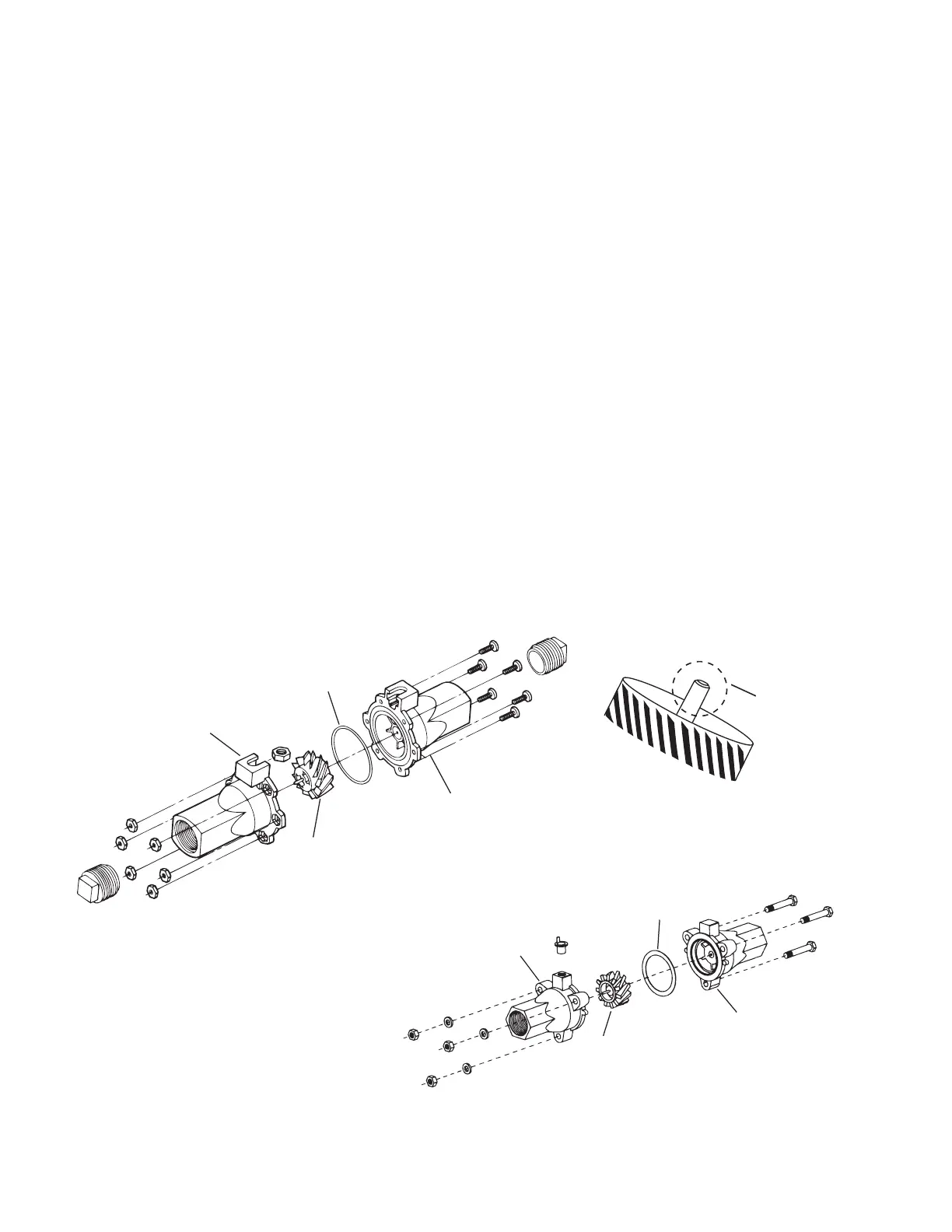

Housing FM750 GFN

Turbine

P/N 14836

Quad-ring

P/N 13783

Housing FM750 GFN

(Non Sensor)

Illustration 26

Complete assembly

FM750 GFN Flowmeter

Housing FM750 SS

Turbine

Gasket

Housing FM750 SS

(Non Sensor)

Illustration 25

New Shaft

Loading...

Loading...