32

Troubleshooting (cont)

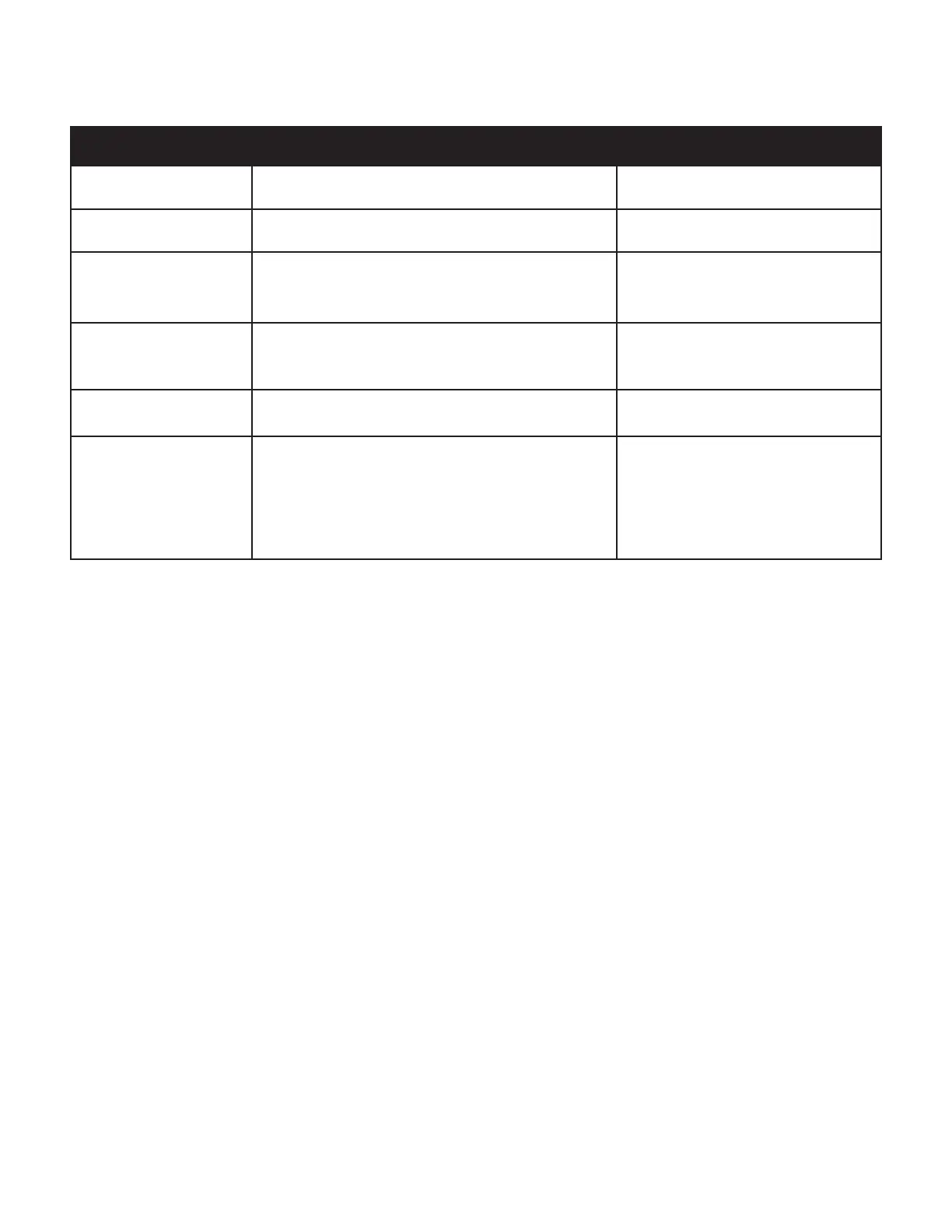

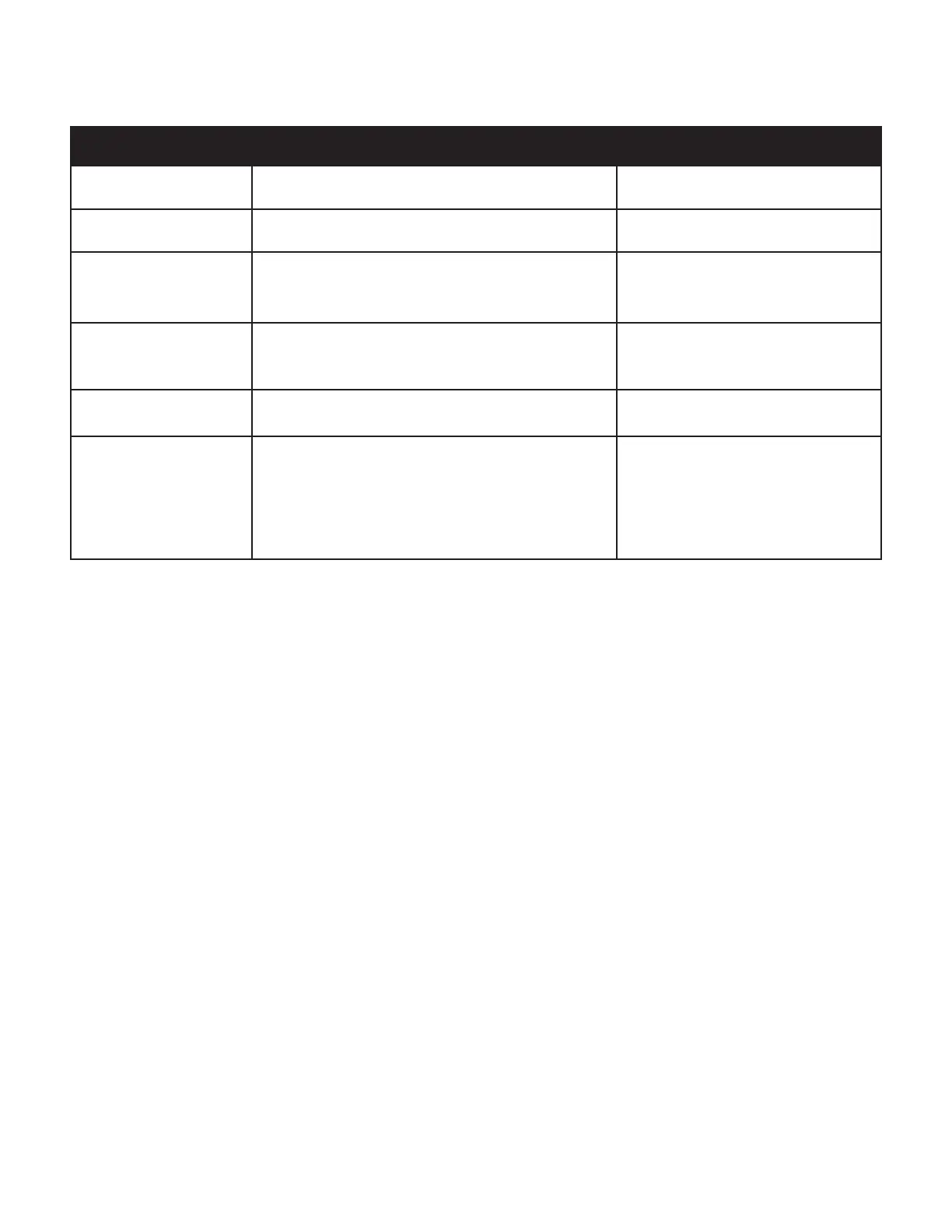

Plumbing Troubleshooting Chart

SYMPTOM POSSIBLE CAUSE POSSIBLE SOLUTION

Loses pressure in

MANUAL

• Pump Air-lock • Clean strainer

• Larger hoses

Little or no pressure

adjustment in MANUAL

• Too much restriction in servo loop • Larger hoses and ttings

• No sharp bends

Pressure won’t go high

enough in MANUAL

• Pump starved or too small

• Too much agitation

• Throttle, range adjust or pressure relief valves

• Larger hoses

• Reduce agitation

• Adjust

Pressure, Speed and

Spray Rate don’t check

out according to charts

• Inaccurate pressure reading

• Dirty or worn tips

• Use a dierent gauge and check

each boom.

• Clean or place

Pressure always goes

too high in AUTO

• Minimum ow rate too high

• Inline/Bypass setting

• Re-calibrate

• Set appropriately

Pressure uctuates

greatly in AUTO

• Sagging or kinked hoses

• Throttle valve too far closed

• Pump starved or too small

• Valve response speed set too high (“Special” Cal)

• Support or replace hoses

• Adjust throttle and range valves

• Larger hoses

• Larger pump

• Clean strainer

• Reduce valve speed setting

* Make sure the sprayer’s flow return adjusting valves are

set properly. See your sprayer’s operating manual for

details, or see Appendix C for basic instructions.

Loading...

Loading...